Carbon Fiber Canopy - Manufacturers, Suppliers, Factory from China

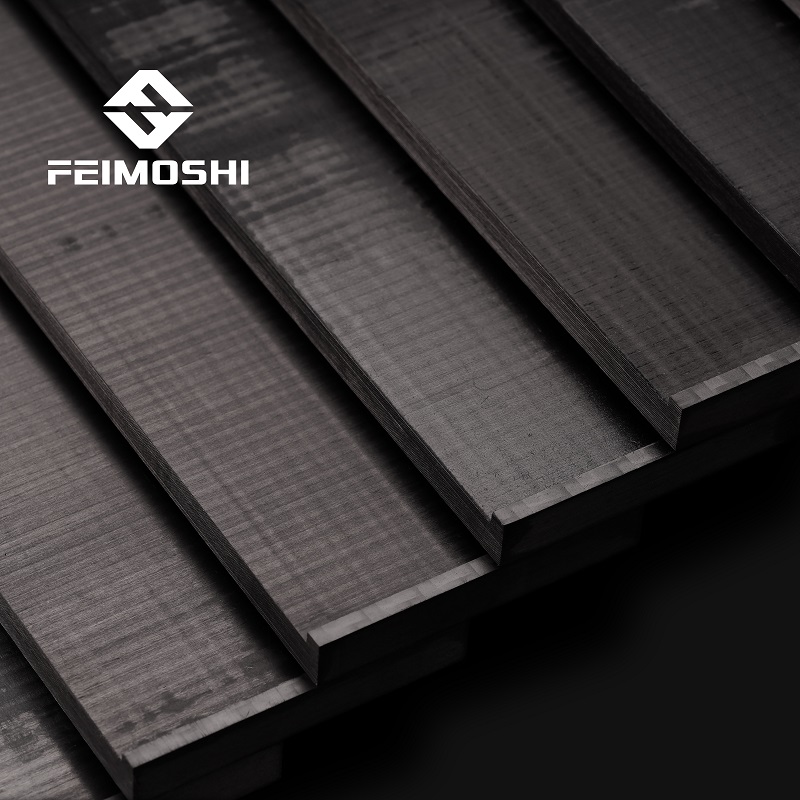

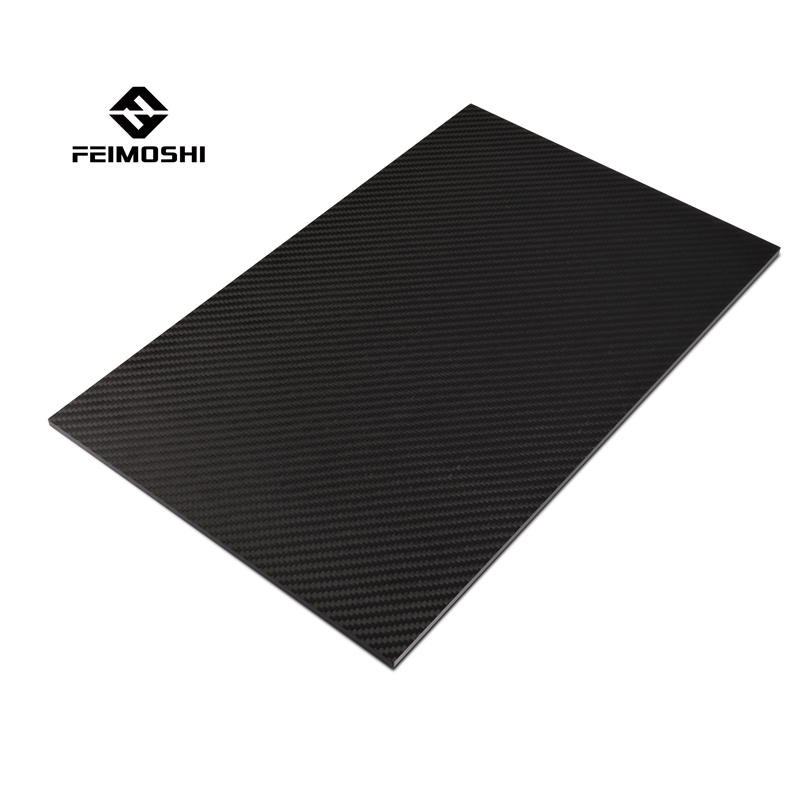

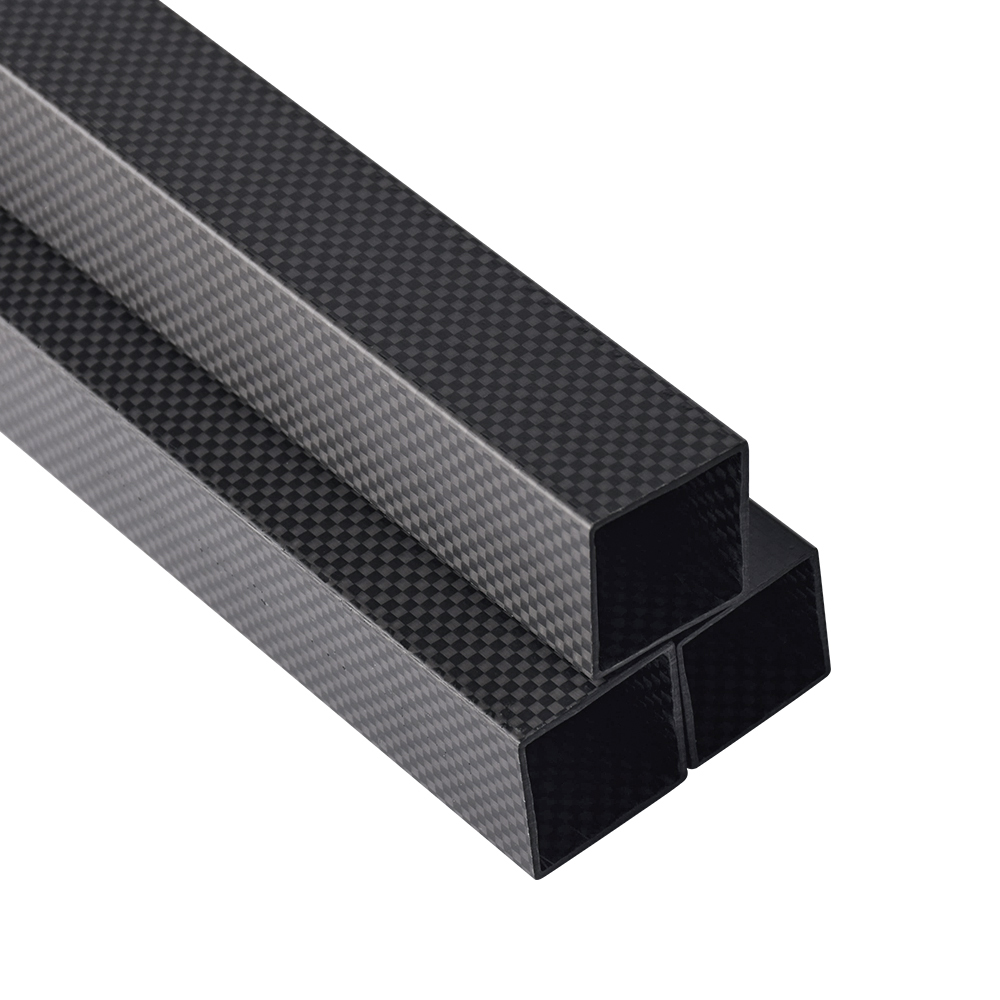

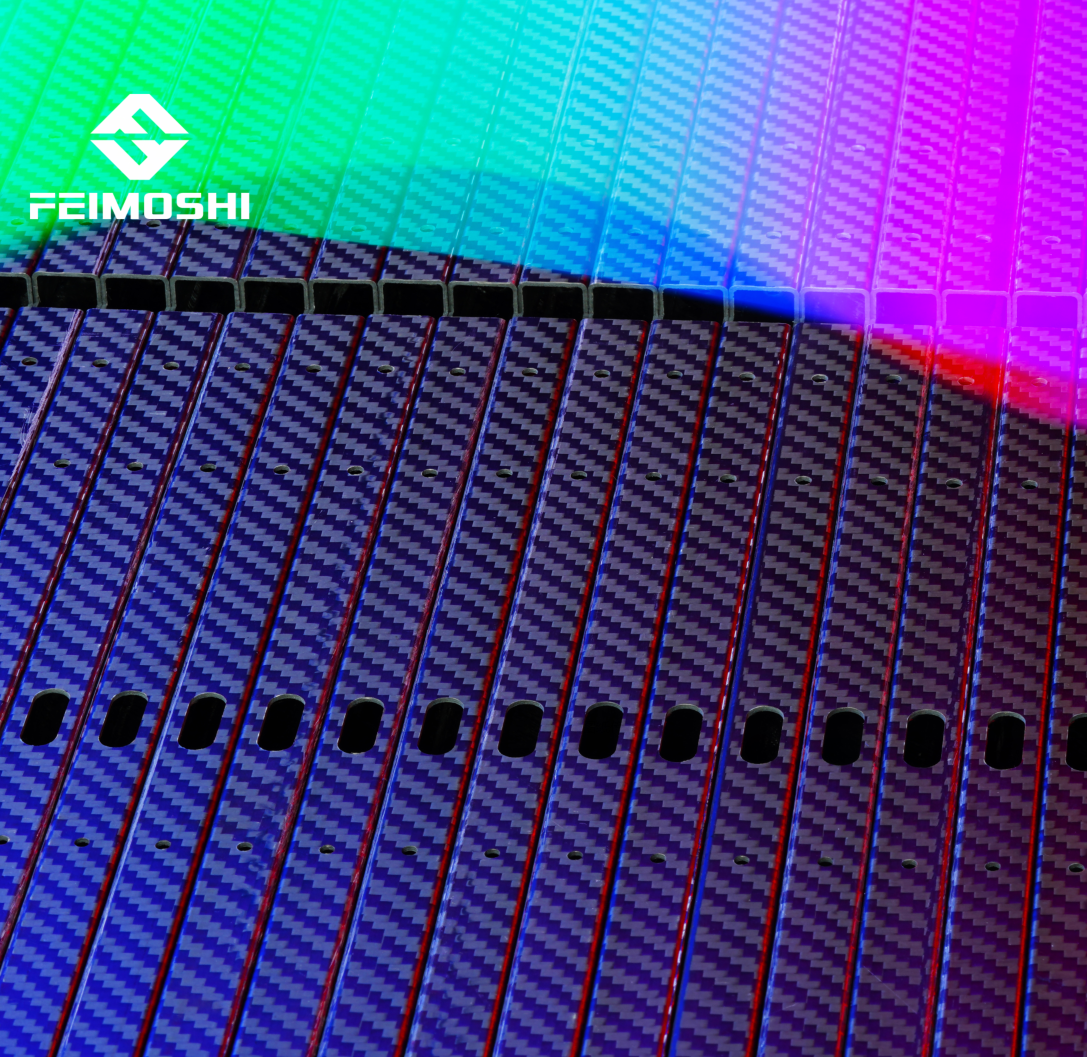

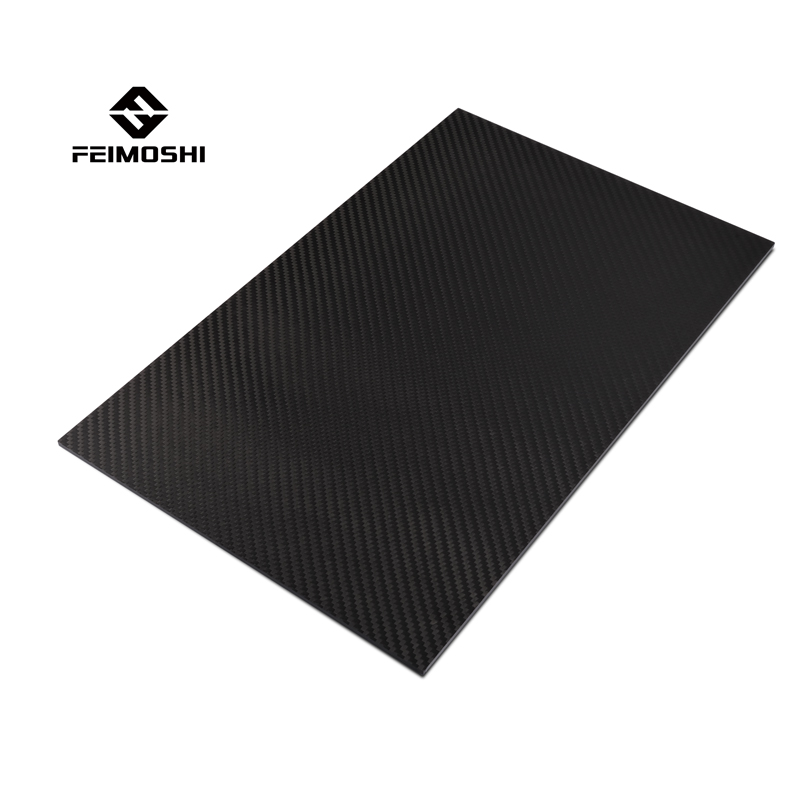

Carbon fiber board is a composite material composed of carbon fiber filaments and resin. The resulting product is lightweight, yet strong and durable. Carbon fiber sheets come in many different types to suit a variety of applications and industries, including automotive and aerospace. Carbon Fiber Canopy, Carbon Fiber Tube Handguard, Keyboard Carbon Fiber Plate, Carbon Fiber Panel,Carbon Fiber Laser Cutting. Carbon fiber board features; A. High tensile strength, good corrosion resistance, shock resistance and impact resistance.Carbon fiber board has excellent physical and mechanical properties, the tensile strength is more than 10-15 times that of ordinary steel, the elastic modulus is better than that of steel, and it has excellent creep resistance, corrosion resistance and shock resistance. It is very suitable for reinforcement and repair of reinforced concrete.B, light weight, good flexibility. Carbon fiber board has higher strength than steel, and its quality is only 1/5 of steel. It has higher toughness, can be coiled, and can be supplied in larger lengths without overlapping. C. The construction is convenient and the construction quality is easy to guarantee.There is no wet operation, no need for large-scale construction equipment, and no need for on-site fixed facilities. The length of the carbon fiber board can be arbitrarily cut, the construction is simple, and the construction period is short. The material does not need to be pre-processed, the process is convenient, and the plates are allowed to cross.D. Good durability and corrosion resistance.Resistant to acid, alkali, salt and atmospheric corrosion without regular maintenance. And it has a protective effect on the internal concrete structure, and can achieve the purpose of double reinforcement and repair. The product will supply to all over the world, such as Europe, America, Australia,Turkey, Bangladesh,Puerto Rico, Danish.In general, grinding and filing can grind the edges of sharp carbon fiber boards to a smooth appearance. However, if the fiberboard is exposed to harsh environments for a long time, such as marine environments, a two-part epoxy laminate is used to seal the edges.According to the different divisions of carbon fiber precursors, there are generally pitch-based carbon fiber cloth, PAN-based carbon fiber cloth, and viscose-based carbon fiber cloth.Second, according to different specifications, it can be divided into 1K, 3K, 6K, 12K and 24K and above carbon fiber cloth.Third, according to different carbonization, it can also be divided into graphitized carbon fiber cloth, (this carbon fiber cloth can withstand high temperature of 2,000 to 3,000), carbon fiber cloth (can cope with high temperature of about 1,000 degrees), and pre-oxidized carbon fiber cloth (can Resist the high temperature of 200~3 Baidu).Fourth, according to different manufacturing methods, subsequent divisions can be performed. Woven carbon fiber cloth, generally two-dimensional cloth, three-dimensional cloth and three-dimensional woven cloth, etc.; carbon fiber prepreg cloth, including dry and wet prepreg cloth; carbon fiber non-woven fabric, non-woven fabric, also known as chopped strand mat, Continuous felt, surface felt, stitched felt, etc.

Related Products