Carbon Fiber Tube - China Factory, Suppliers, Manufacturers

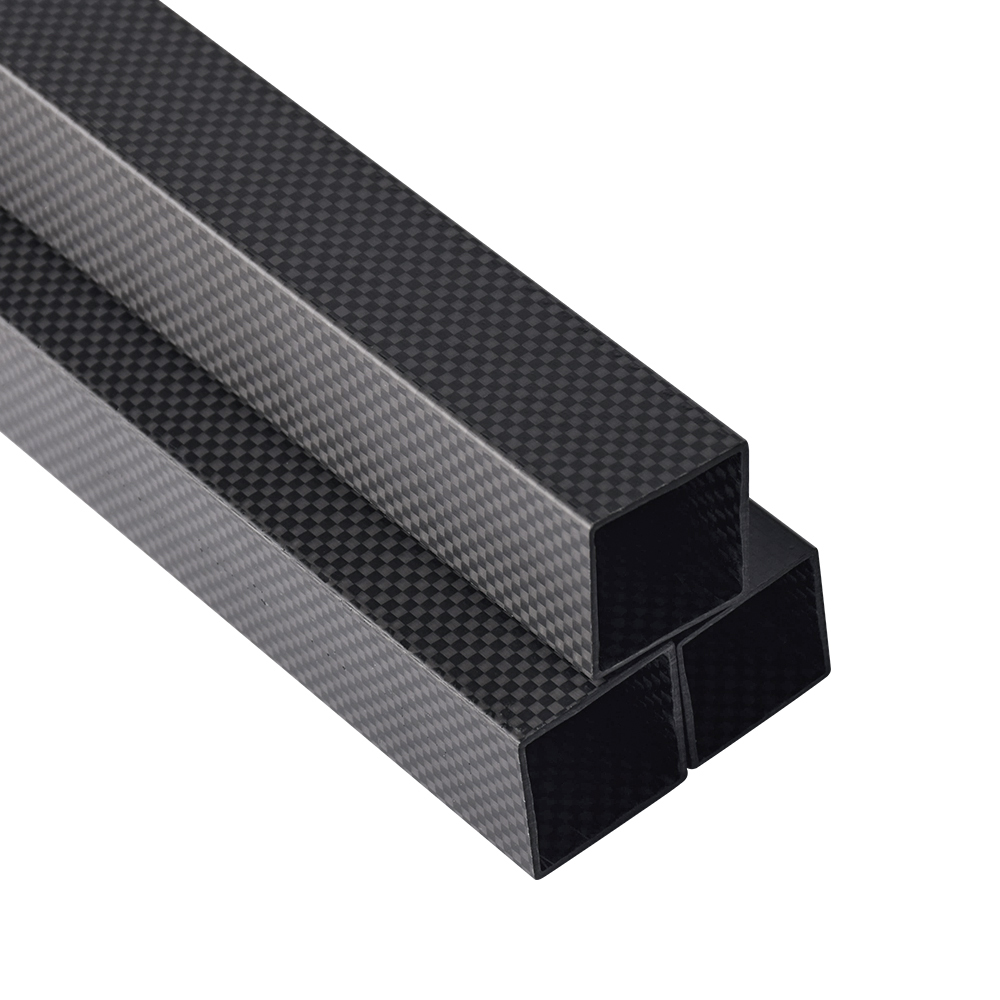

In the aerospace industry, carbon fiber sheets are used to make aircraft components such as fuselage panels, control surfaces and wingtips. The resulting components are lightweight, yet robust. Carbon fiber is widely adopted by the aerospace industry due to its superior strength-to-weight ratio. Because carbon fiber has such a beautiful appearance, it is also ideal for aircraft interiors. Carbon Fiber Tube, Composite Boom, Design Carbon Fiber, Custom Carbon Fiber Wallet,Carbon Fiber Tube Drilling. When the surface moisture is completely dry, you can design and make the driving path of the spray gun according to the shape of the carbon fiber tube to carry out spray painting. When painting, pay attention to the evenness of the paint. Generally, the carbon fiber tube has to be sprayed three times: topcoat, varnish, and surface clear paint, and each time it is sprayed, it must be baked once. During the whole process of painting, it is found that there are paint particles or dents on the surface of the carbon fiber tube, and it must be polished or compensated until the surface is smooth, so that the painting process of the carbon fiber tube is completed. The product will supply to all over the world, such as Europe, America, Australia,New Zealand, St. Petersburg,Maldives, Comoros.There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

Related Products