Factory wholesale Making Carbon Fiber Sheets - custom carbon fiber parts by CNC cutting – Feimoshi

Factory wholesale Making Carbon Fiber Sheets - custom carbon fiber parts by CNC cutting – Feimoshi Detail:

Description:

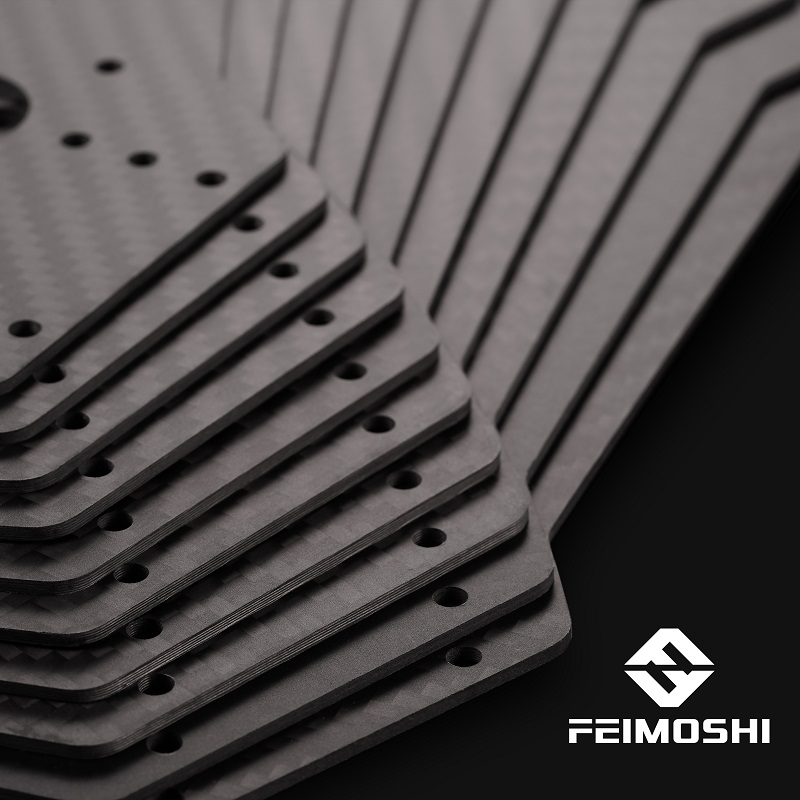

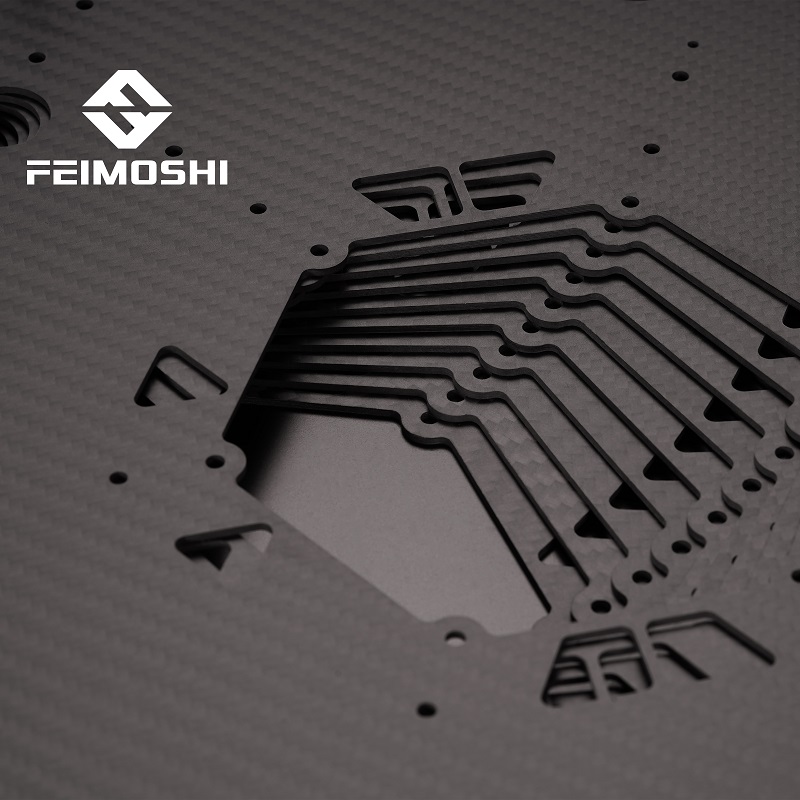

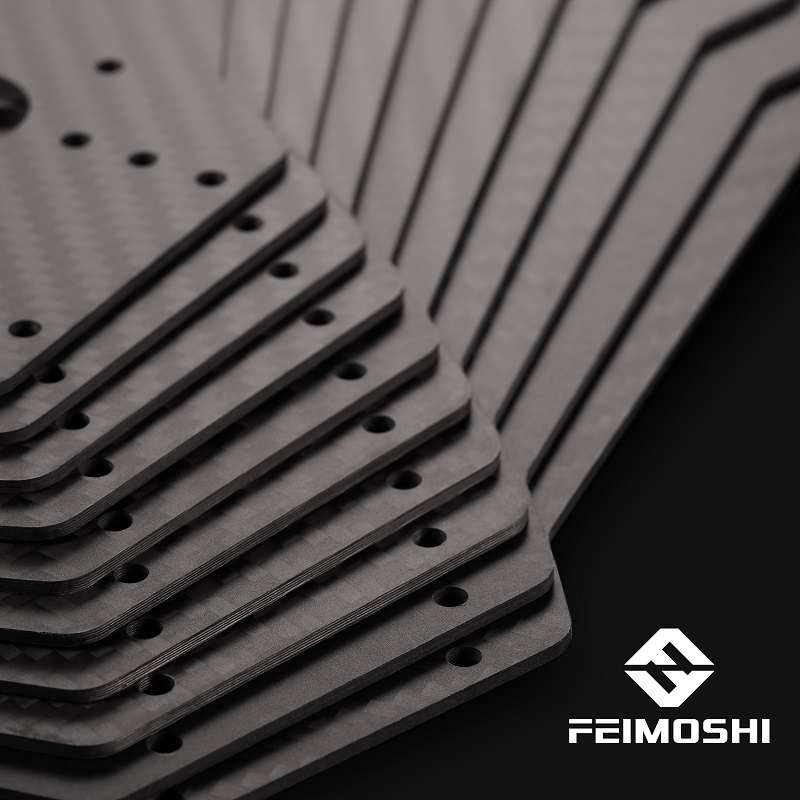

Cnc Carbon Fiber Cutting parts are made of carbon fiber plate through CNC machining. Compared with other materials, carbon fiber has more outstanding features, such as high strength, light weight, anti-aging, it’s widely used in different fields. We supply customized carbon fiber CNC machining service according to your drawings.

CNC service:

We are professional in carbon fiber plates and carbon fiber sheets CNC cutting for Drones /FPV for more than 10 years

We have been cooperating with lots of famous brand.

We do cutting according to our customers’ design(file with .dxf format) and we protect each design for our customers.

Product detail pictures:

Related Product Guide:

3. Carbon fiber material shock absorber. It is manufactured from epoxy rubber sheet and carbon fiber production, and has the original vibration damping properties of high bending stiffness raw materials. Often in the case of industrial equipment, this type of feature will quickly reduce the vibration caused by sports and fitness, high stability, and improve production efficiency. In addition, it is also helpful for reducing load and extending life. Factory wholesale Making Carbon Fiber Sheets - custom carbon fiber parts by CNC cutting – Feimoshi , The product will supply to all over the world, such as: Costa rica, New Zealand, Turin, The characteristics of carbon fiber tube:1. High tensile strength: The strength of carbon fiber is 6-12 times that of steel, which can reach more than 3000mpa.2. Low density and light weight. The density is only less than 1/4 of steel.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

Send your message to us:

Write your message here and send it to us