High definition Composite Plate Fit - custom 20mm thick CNC cutting machine carbon fiber sheet for construction – Feimoshi

High definition Composite Plate Fit - custom 20mm thick CNC cutting machine carbon fiber sheet for construction – Feimoshi Detail:

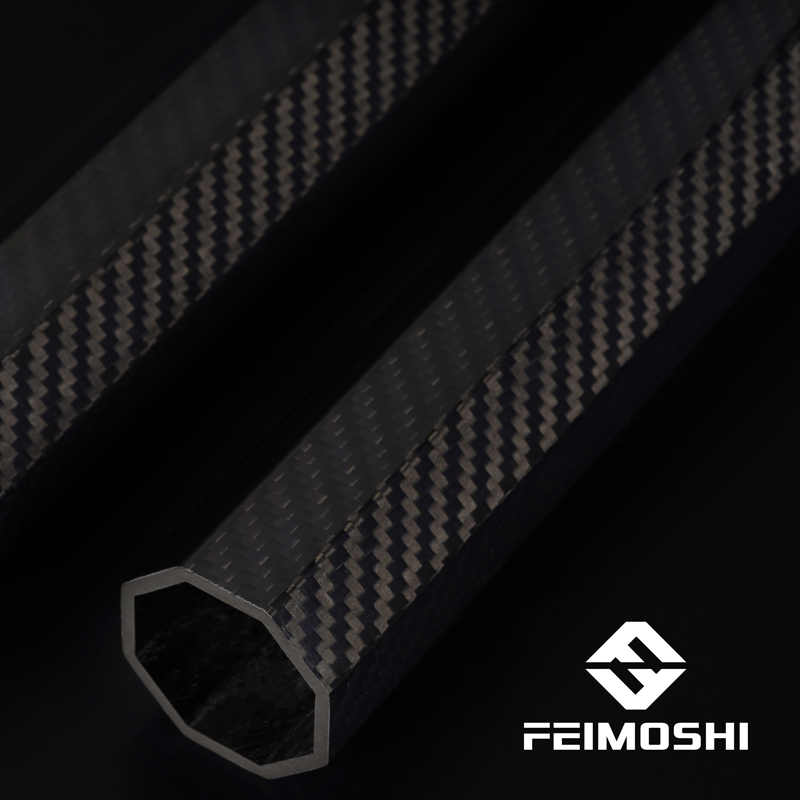

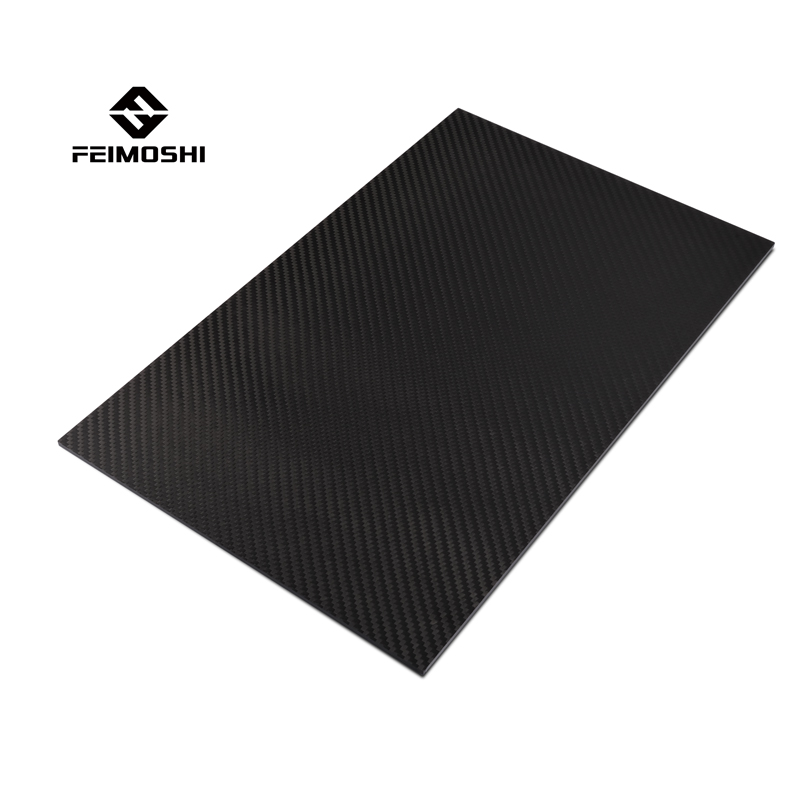

custom 20mm thick CNC cutting machine carbon fiber sheet for construction

Custom cutting machine Full Carbon Fiber Sheet have many advantage, Stiffer, stronger, and lighter than steel and aluminum, carbon fiber works miracles reinforcing materials and lifting many industries to new levels of performance.The future of carbon fiber is very bright, with vast potential in many different industries. So many advantages help to custom cutting machine. carbon fiber sheet quickly become the leader of the drone market, widely use in the uav and fpv market. If any need of custom cutting machine carbon fiber sheet, please feel free to contact us.

Surface: 3K twill matte

Finish: matte or glossy in both sides, twill or plain weave

Stock: twill matte 0.5-10.0mm pure carbon fiber plates in stock

Service: OEM & ODM and CNC services, Logo Service,Carbon Fiber CNC Cutting

FAQ

1) Do you produce the thick carbon fiber sheet?

Yes, 20.0mm, 30.0mm thick carbon fiber sheet is ok for us.

2) Can you do the countersunk or chamfer on carbon fiber material?

Yes, countersunk could help to reduce the weight and do the logo on carbon fiber sheet. Carbon fiber chamfer could make the edge round and smooth.

3) Do you offer the cutting service?

Yes, CNC cutting is ok according to your drawings. We will make the quotation according to the drawings’ comprehensive.

4) MOQ requirements?

Normally, one 400X500mm plate or 500X600mm plate for cutting is fine.

5) How many days do you need for the cutting?

Normally, it needs about 7-10 working days for cutting.

Looking for ideal Carbon Fiber Sheet Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Sheet Cutting are quality guaranteed. We are China Origin Factory of Custom Cutting Machine Carbon Fiber Sheet. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The basic properties of chopped carbon fiber are mainly inherited from its raw material, continuous carbon fiber. What kind of continuous carbon fiber is used as the raw material also directly determines the price of chopped carbon fiber. The tensile strength of continuous carbon fibers directly affects the tensile properties of chopped carbon fiber composite thermoplastics. Some chopped carbon fiber manufacturers will mix different types of continuous carbon fibers due to insufficient raw material supply or cost issues, but this will lead to unstable properties of chopped carbon fiber composite thermoplastic materials. Therefore, when purchasing chopped carbon fiber, it is best to ask the supplier to indicate the type or main performance of continuous carbon fiber on the quality inspection sheet. High definition Composite Plate Fit - custom 20mm thick CNC cutting machine carbon fiber sheet for construction – Feimoshi , The product will supply to all over the world, such as: Turin, Swiss, Jordan, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.