Carbon fiber tube, also known as a carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin by heating, curing, and pultrusion (twisting). In the manufacturing process, various profiles can be produced through different molds, such as carbon fiber round tubes of different specifications, square tubes of different specifications, sheets of different specifications, and other profiles: 3K can also be packaged during the production process. Surface packaging beautification and so on.

Carbon fiber tube has the advantages of high strength, long life, corrosion resistance, lightweight and low density. It is widely used in kites, aviation model airplanes, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment, and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, low thermal expansion coefficient, self-lubricating, energy absorption, and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high-temperature resistance, corrosion resistance, wear resistance, etc.

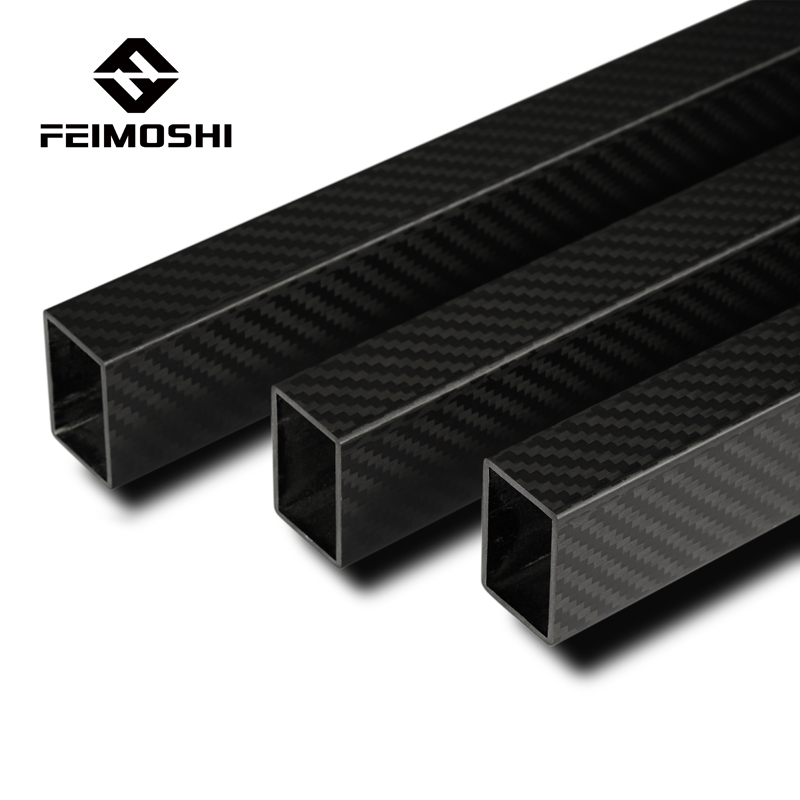

Specification of carbon fiber pipe:

Carbon fiber tubes generally have several forms such as square tubes, round tubes, and special-shaped tubes. The processing methods include rolling, pultrusion, and winding. The surface can be divided into the plain weave, twill weave, and pure black. In addition, it can be processed into two forms of matte and bright. Commonly used carbon fiber round pipes have a diameter between 10 and 80 mm, the longest can be 10 meters, and the thickness is generally between 0.5 and 5 mm.

The product quality of carbon fiber tubes is greatly affected by the processed porosity. The voids have a great influence on the interlayer shear strength, bending strength, and bending modulus; the tensile strength decreases relatively slowly with the increase of the porosity; the stretching Modulus is less affected by porosity.

Carbon fiber tubes are currently widely used in the industrial field. In addition to aerospace and military products, due to their unique lightweight and high-strength characteristics, kite frames, drone racks, robotic arms, medical supports, sporting goods, etc., are used in the civil field. There is a lot of use. Carbon fiber tube is an excellent product to upgrade and replace traditional materials. To improve the quality and experience of the product, carbon fiber is an excellent choice

Post time: Sep-23-2021