Carbon fiber prepreg is a raw material for carbon fiber board processing. According to its tow size, it can be divided into 1k, 3k, 6k, 12k, etc., generally 3k is mostly used. Jiangsu Boshi Carbon Fiber will also process the surface of the carbon fiber board according to the needs of customers, such as plain/twill, bright/matte, and engraving according to requirements in the later period. The production process of carbon fiber board includes cutting, laying, curing, cutting and post-processing of carbon fiber prepreg.

1. Tailoring of prepreg:

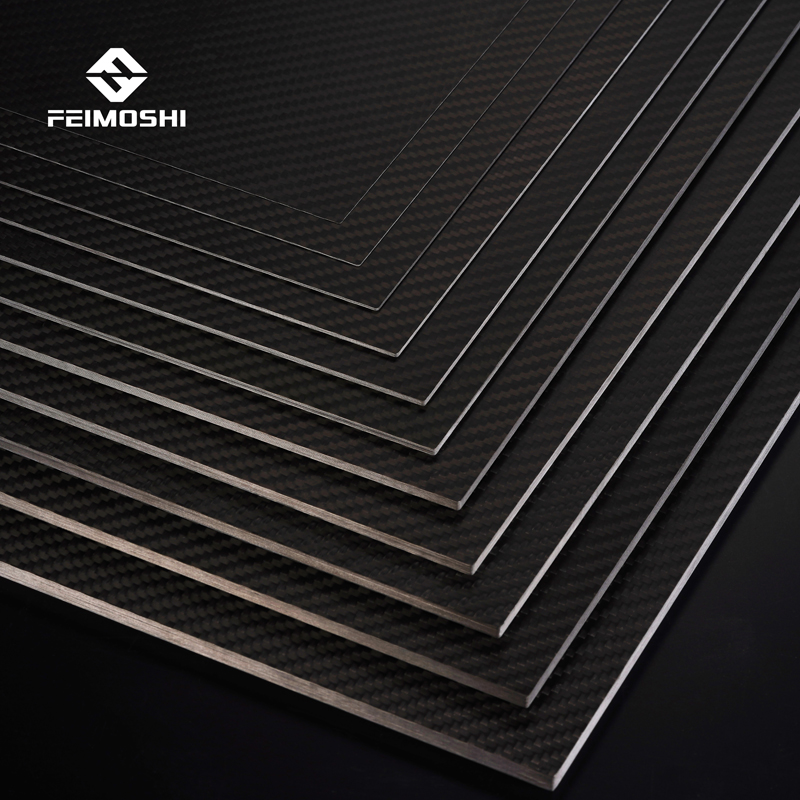

First, we need to cut the prepreg according to the length and width of the carbon fiber sheet, and determine the required prepreg thickness according to the thickness of the sheet. Jiangsu Boshi Carbon Fiber has many years of rich experience in the production of carbon fiber boards. Carbon fiber boards of different thicknesses can be customized according to customer needs. The conventional board thicknesses are: 0.2mm, 0.5mm, 1.0mm, 1.5mm, 2.0mm, 3.0mm , 5.0mm, 6.0mm, 10.0mm, 20mm, etc.

The thicker the sheet, the more layers of carbon fiber prepreg are required. Generally, a 1mm carbon fiber board requires about 5 layers of prepreg. Boshi introduced an imported automatic cutting machine to cut the prepreg, which can better control the size and quality of the cutting. Boshi designers will optimize the design before cutting, which can increase the utilization rate of the prepreg and reduce the generation of margins, thereby helping customers reduce production costs.

2. Laying of prepreg:

The difference of the layup sequence will not only affect the initial load, growth rate, and fracture toughness of the matrix cracks, but also have a significant impact on the saturation and crack density of the matrix cracks. For example, for orthogonal laminates, there is a corresponding relationship between fracture toughness and crack growth rate under the same external load. Therefore, technicians are required to determine the direction and order of layup of the prepreg according to the requirements of the sheet for tensile force, shear force and strength. Give full play to the advantages of carbon fiber composite materials.

The laying direction of the prepreg should be set according to the main direction of the load. The laying direction includes 0°, ±45°, and 90°. In the state of shear stress, the layer with an angle of 0° corresponds to the normal stress, the layer with an angle of ±45° corresponds to the shear stress, and the layer with an angle of 90° is used to ensure that the carbon fiber product has sufficient positive pressure in the radial direction. According to the staff of Boshi, if the load of the carbon fiber board is mainly tensile and compression load, then the direction of the layup should be the direction of the tension and compression load; if the load of the carbon fiber board is mainly the shear load, then the layup In the middle, it is mainly to lay in pairs of ±45°; if the load of the carbon fiber board is complex and includes multiple loads, then the paving design should be mixed in multiple directions of 0°, ±45°, and 90°.

3. Curing of prepreg:

After the carbon fiber prepreg is cut and laid up in an orderly manner, it will enter the heating and pressure curing process. The laminated prepreg is placed in a mold with a set temperature and heated and pressurized. The mold is closed. The laminated material gradually solidifies under hot pressure and reaches a certain degree of solidification. The mold opens and is pulled by the traction device. Press the mold to complete the curing.

During the entire curing process, the heating and pressing time needs to be adjusted according to the different needs of the carbon fiber board. Different temperatures and heating time will have an impact on the material properties of carbon fiber sheets. In the actual production process, the time of the hot pressing stage should be shortened as much as possible under the premise of maintaining dimensional stability during the post-curing stage of the part.

The carbon fiber board produced by Jiangsu Boshi Carbon Fiber can select the appropriate production process according to the customer’s technical requirements to ensure product stability, surface treatment, thickness tolerance, etc., and product quality can be effectively guaranteed.

4. Post-processing of plates:

After the carbon fiber board is solidified and formed, cutting, drilling and other post-processing are required for accuracy requirements or assembly needs. Under the same conditions of cutting process parameters, cutting depth, etc., the effect of choosing tools and drills of different materials, sizes, and shapes is very different. At the same time, factors such as the strength, direction, time and temperature of the tools and drills will also Affect the result of processing.

Post time: Sep-23-2021