2021 Good Quality Cut Cnc - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi

2021 Good Quality Cut Cnc - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi Detail:

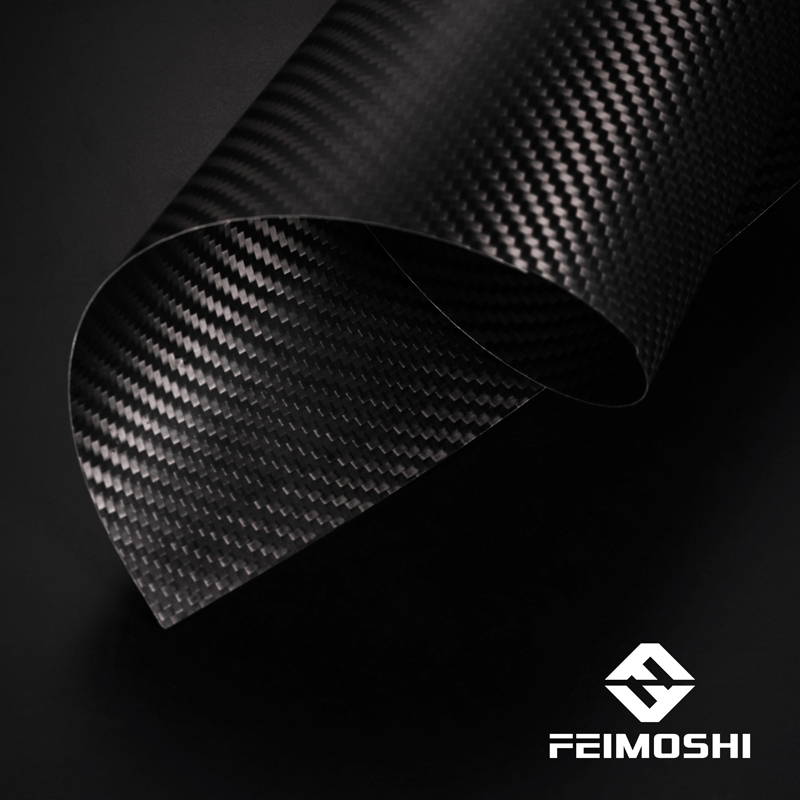

2.0mm Twill matte CNC carbon fiber composite cutting opener mount

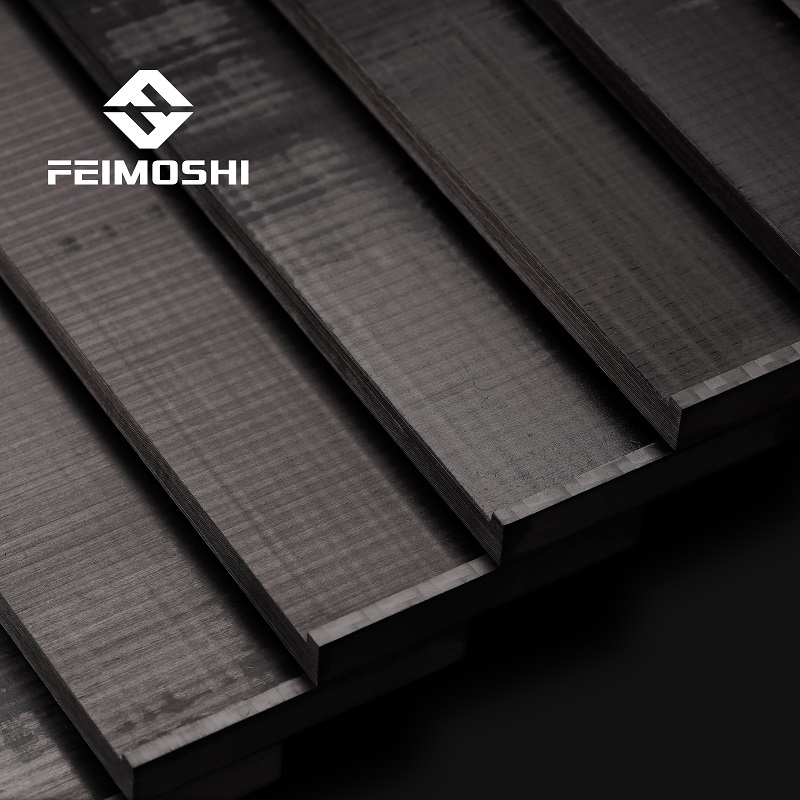

400X500X2.0mm and 500X600X2.0mm 3K twill matte carbon fiber plate could be cut to different types. 2.0mm thickness is very suitable for the carbon fiber opener. Normally, we could do some stocked quantity for 2.0mm thickness. Carbon fiber sheet is made of 3K twill matte cloth and UD cloth and epoxy resin.

CNC cutting service is ok for us. If you feel that the edge is very sharp, we could do the chamfer for the edge to make it more professional. Also wanting to connect the hardware with carbon fiber parts, contact us freely. Our engineer team will offer some good suggestions for your choosing.

Product detail pictures:

Related Product Guide:

In recent years, the demand for carbon fiber has maintained a steady upward trend, and enterprises and investment institutions are also optimistic about the development prospects of the carbon fiber industry. What's new. At the same time, the carbon fiber industry has a wide range of applications, and its M&A demand and activity are also very obvious. 2021 Good Quality Cut Cnc - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi , The product will supply to all over the world, such as: Bahamas, Japan, New Zealand, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Send your message to us:

Write your message here and send it to us