2021 High quality Cutting Carbon Fiber - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi

2021 High quality Cutting Carbon Fiber - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi Detail:

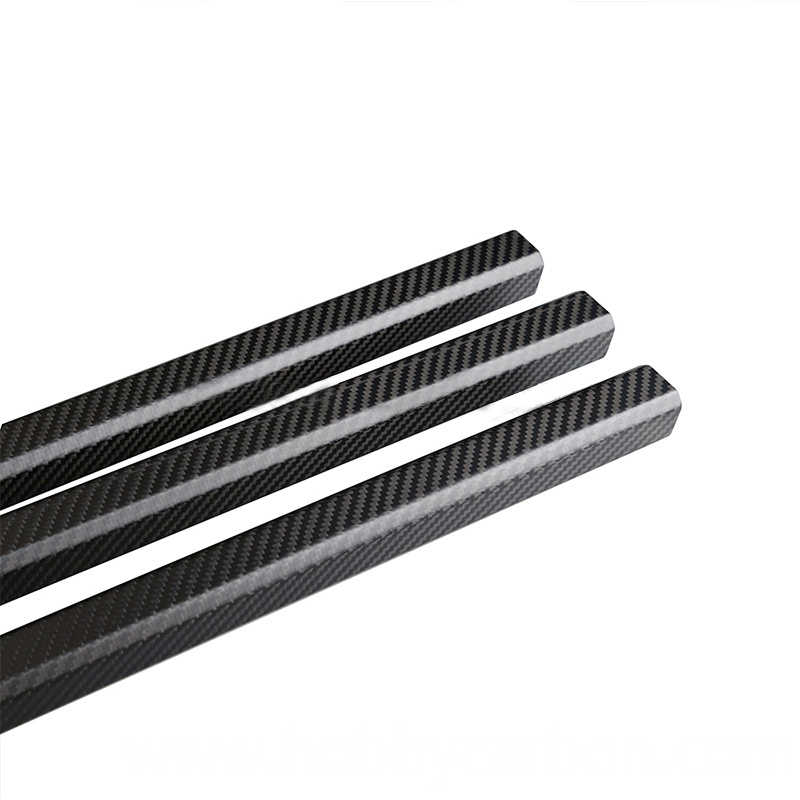

Customized carbon fiber octagonal tube accessories

New upgrading Octagon carbon fiber boom types in stock: 20X30mm, 30X30mm(Length is 1000mm.) We could cut the different length according to your detail requirements( Free cut length charge)

Thicknesss could do the 1.0mm, 1.5mm and 2.0mm or others. Octagon carbon fiber tube is more stable and professional than round carbon fiber tube.

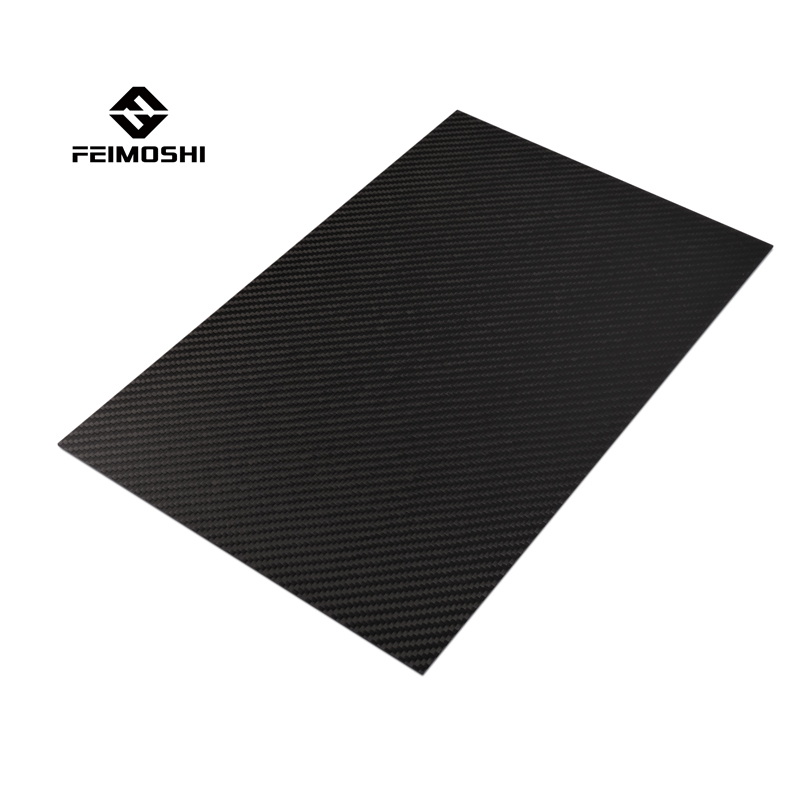

These 3K Carbon Fiber Tubes Carbon are made of pure carbon fiber with beautiful twill or plain weave;

Customized specs are accepted, like Outer Diameter : 6mm, 8mm,10mm,12mm,14mm,16mm, 20mm, 22mm, 25mm, 30mm……350mm;

Thickness:

1mm, 1.5mm, 2 mm, 2.5mm, 3mm…..16mm ;any size can do for you .

2.Specifications

1) High temperature resistance carbon fiber tubes:100%carbon fiber ;

2) Light & high strength;

3) Good corrosion resistance;

Besides Carbon Fiber Tube, we also can support you with Full Carbon Fiber Sheet, shaped carbon fiber parts, carbon fiber prototyping, carbon fiber guitar, carbon fiber rc chassis and carbon fiber furniture and so on.

We have about ten years more experience in carbon fiber market. Assembly serivce and packing service is welcomed by most customers. Any other requirements, please don’t hesitate to contact us.

Welcome to quote

Specification in common use

|

23mm*25mm*1000mm |

20mm*22mm*1000mm |

|

19.5mm*22mm*1000mm |

18mm*20mm*1000mm |

|

18mm*16mm*1000mm |

14mm*16mm*1000mm |

|

10mm*12mm*1000mm |

8mm*10mm*1000mm |

|

6mm*8mm*1000mm |

can custom as per customer’s requires |

FAQ

1) Do we need to make a mould for the shaped carbon fiber tube?

Yes, most of carbon fiber tube needs a mould to do it. And it will make the tube more straight and strength.

2) There is the moq requirements of shaped carbon fiber tube?

If you make the new mould for your project, the testing order is no moq for you.

3)When we decide to make the mould, it needs to make the payment for each order?

No, mould charge only need to pay one time. Ant the mould is only for you.

4) Could we sign the NDA?

Yes, it is ok for us. And it is also our duty to protect every customer’s design.

Looking for ideal Carbon Fiber Arms Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the X Class Frame are quality guaranteed. We are China Origin Factory of Big Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. 2021 High quality Cutting Carbon Fiber - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi , The product will supply to all over the world, such as: belarus, Mexico, Milan, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.