Bottom price Carbon Fiber Plate In Stock - OEM 1K 3K carbon fiber board sheet for Sale – Feimoshi

Bottom price Carbon Fiber Plate In Stock - OEM 1K 3K carbon fiber board sheet for Sale – Feimoshi Detail:

Shape: Carbon Plate, Carbon Fiber Tube, CARBON ROD

Species: Carbon Fiber Cloth, Carbon Fiber Board/ Panels, Carbon Fiber

Service: OEM/ODM

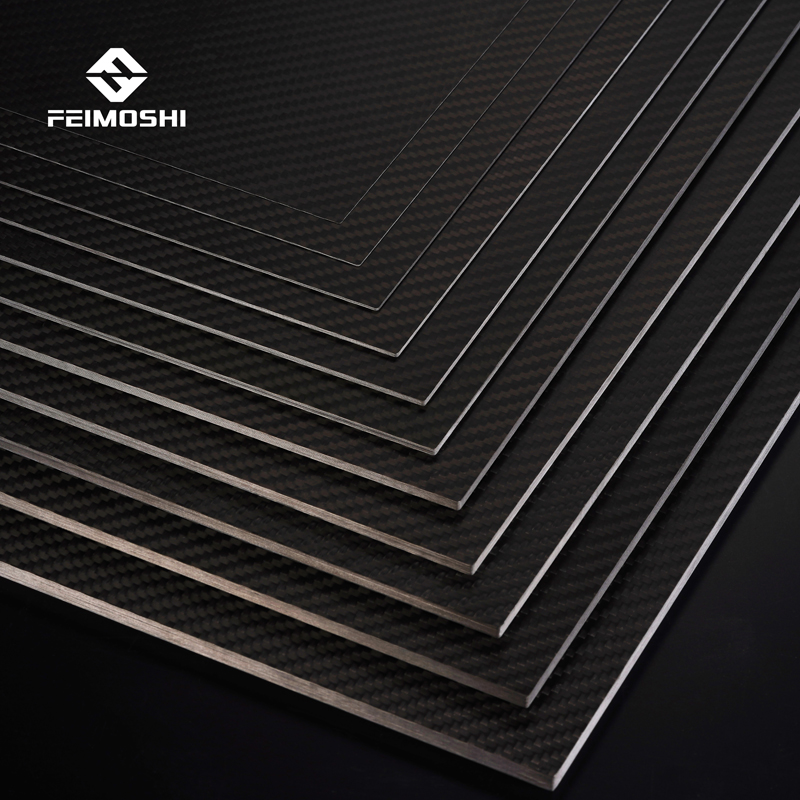

Tolerance: +/-0.1mm-0.2mm for thick

Processing: CNC Precise cutting

Delivery Time: About 7-15 Working Days

Extra Service: Assembly/Packing Or Others.

Shipping Way: DHL/Fedex/HongKong Post Or Others

Measurement: Different Type Is Ok For Us

Packaging: Plastic bag or Carton box

Certificate: ISO9001

Payment Type: T/T,Paypal,Western Union

Incoterm: EXW

Packaging & Delivery

Selling Units: Piece/Pieces

Package Type: Plastic bag or Carton box

Picture Example:

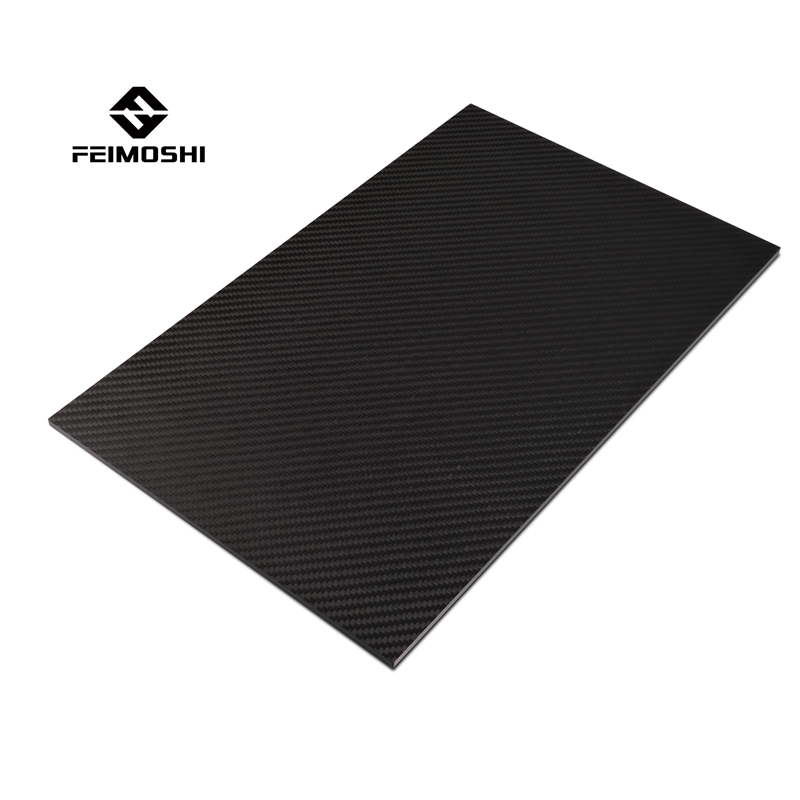

OEM carbon fiber board sheet for Sale

CNC Carbon Fiber Cutting is a special way to help customers get the unique frame to produce their drones in the market. We made many cooperation with many popular brand and also get more and more good feedback.

More quantity, more competitive price for your FPV frame.

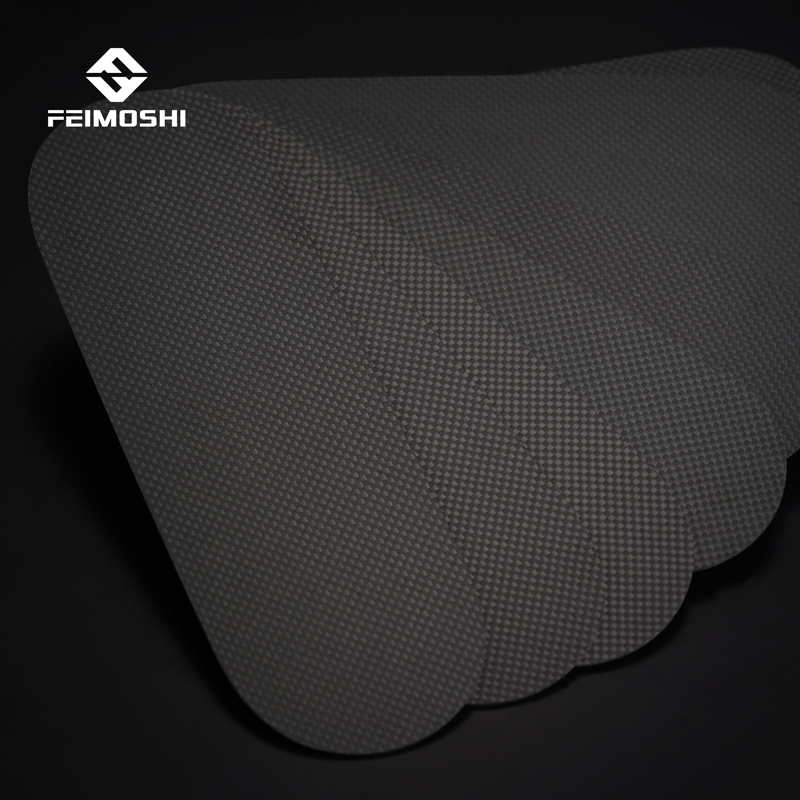

Carbon fiber is a kind of special fiber mainly composed of carbon elements, and its carbon content varies with different types, generally more than 90%. Carbon fiber has the characteristics of general carbon materials, such as high temperature resistance, friction resistance, electrical conductivity, heat conduction and corrosion resistance, etc. However, different from general carbon materials, its shape is significantly anisotropic, soft, and can be processed into various fabric. The fabric exhibits high strength along its direction. Carbon fiber has a small specific gravity, so it has a high specific strength.

Product Description

Material: Carbon fiber part

Size :Customized (welcome to customeied)

Surface: Twill/Plain Matte/Glossy or other colors

Stock: Normal plate are in stock

Service: OEM & ODM,Cnc Cutting Service And Logo Printing,CNC Customized Hardware, Logo Service

Looking for ideal 1/4 Thick Carbon Fiber Sheet Manufacturer & supplier?

We have a wide selection at great prices to help you get creative. All the OEM Carbon Fiber Sheet are quality guaranteed. We are China Origin Factory of OEM Carbon Fiber Sheet for Sale. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

3. Carbon fiber material shock absorber. It is manufactured from epoxy rubber sheet and carbon fiber production, and has the original vibration damping properties of high bending stiffness raw materials. Often in the case of industrial equipment, this type of feature will quickly reduce the vibration caused by sports and fitness, high stability, and improve production efficiency. In addition, it is also helpful for reducing load and extending life. Bottom price Carbon Fiber Plate In Stock - OEM 1K 3K carbon fiber board sheet for Sale – Feimoshi , The product will supply to all over the world, such as: Sao Paulo, venezuela, Washington, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.