China Cheap price Carbon Fiber Cutting Part - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi

China Cheap price Carbon Fiber Cutting Part - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi Detail:

Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max

The ultra-thin autoclave kevlar phone case is on sale. Its main features are thinness, toughness, high-quality appearance, and comfortable touch.

Material: autoclave kevlar

Thickness: 0.35mm ultra thin

Finish: autoclave process

MOQ: 10pcs

Color: black, red, blue

Shipping methods: Express services like DHL, UPS, FedEx, TNT, or Air shipping, Sea shipping

Why choose Autoclave phone case?

Easy to use even with complex curvature of the product

Zero voids.

Perfect appearance of the carbon fiber fabric.

Excellent fatigue resistance.

Laminate thickness keeped under control.

The process is clean.

The process offers better quality as well as conformity.

Why choose Aramid/Kevlar fibers?

High strength

Good resistance to abrasion

Good resistance to organic solvents

Non-conductive

No melting point

Low flammability

Good fabric integrity at elevated temperatures

Note: We support free sample service!

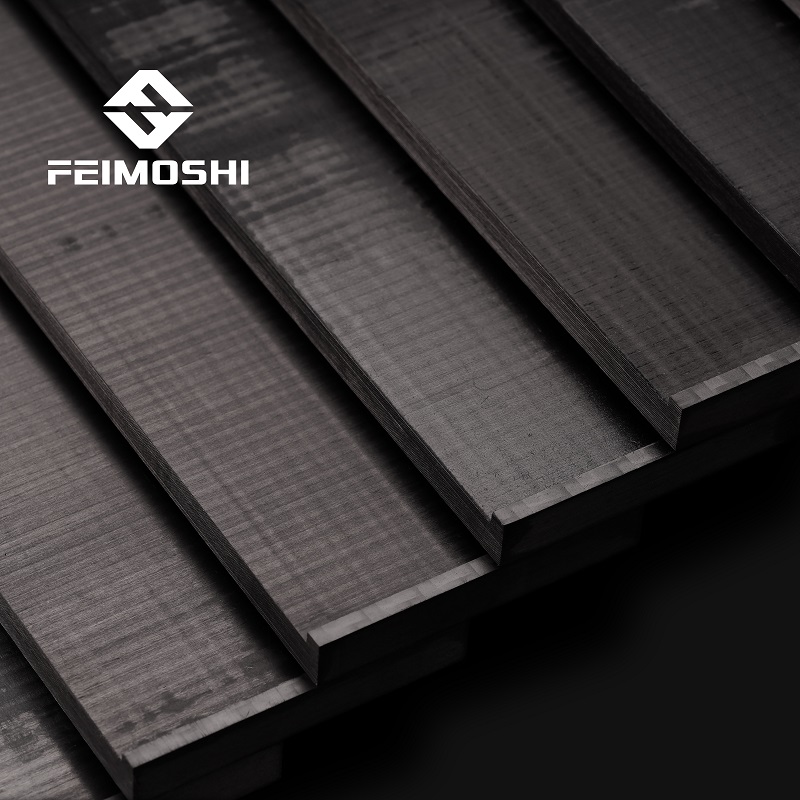

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. China Cheap price Carbon Fiber Cutting Part - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi , The product will supply to all over the world, such as: Johannesburg, Latvia, Hyderabad, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.