China Cheap price Composite Part - 3K carbon fiber CNC cutting parts – Feimoshi

China Cheap price Composite Part - 3K carbon fiber CNC cutting parts – Feimoshi Detail:

3K Carbon Fiber CNC Cutting parts

Have you designed your own frame and are looking to have it cut?

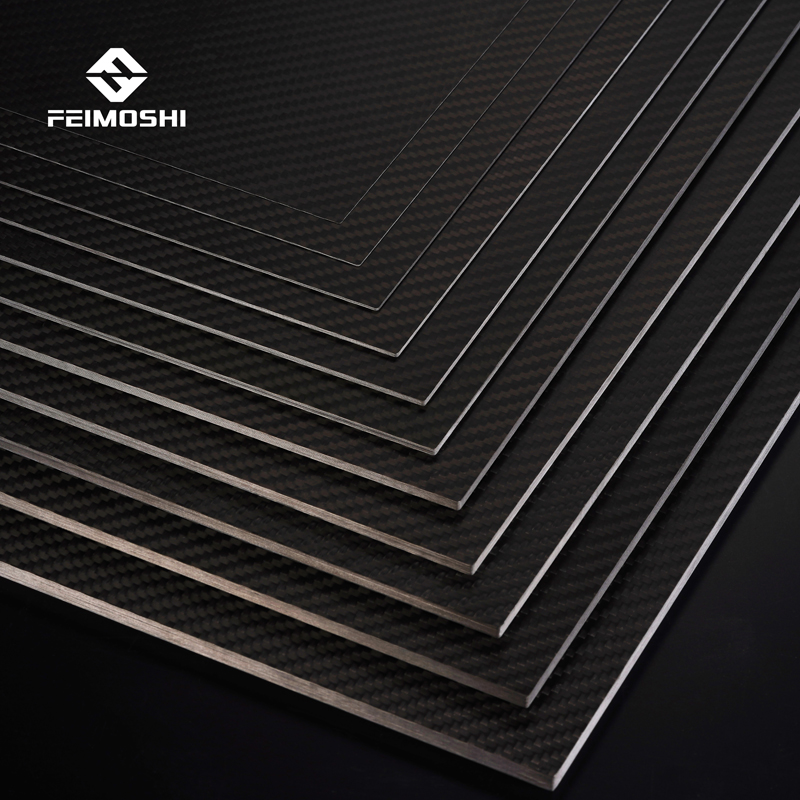

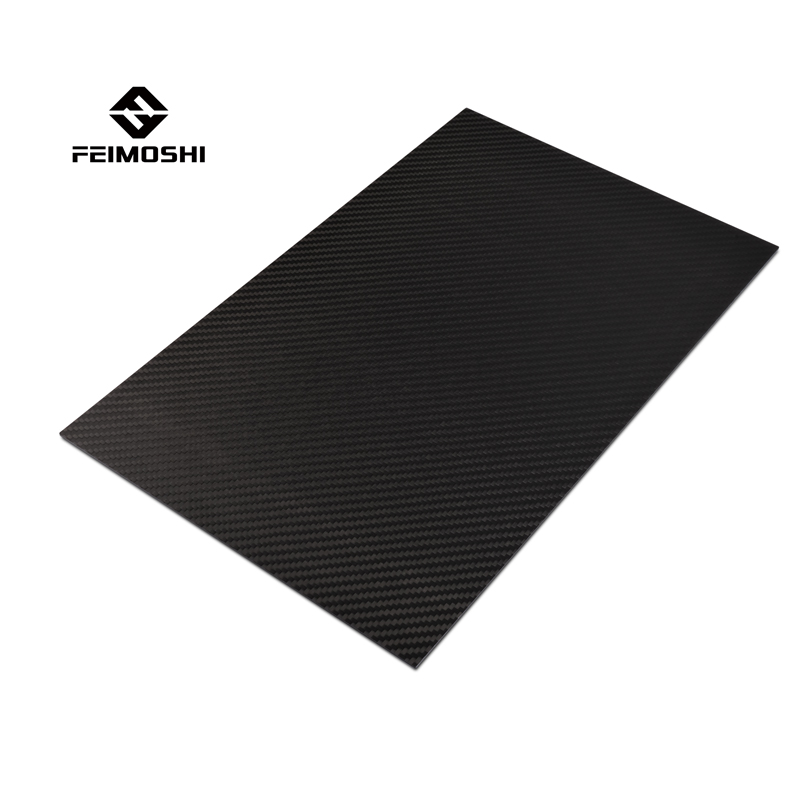

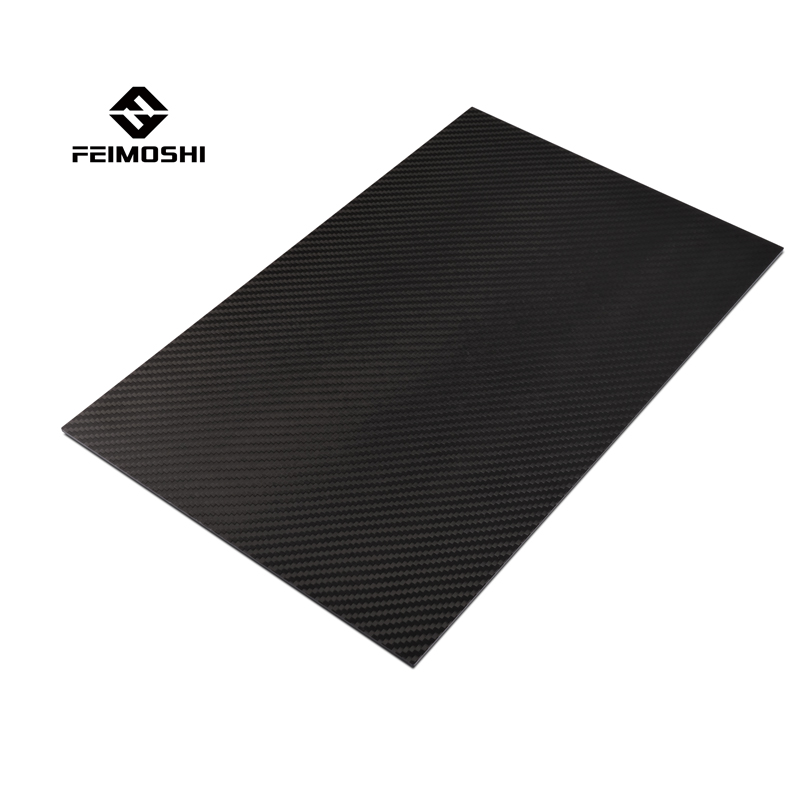

We can turn it into a reality for you. We carry high quality 3K Twill, Matte Finish Carbon Fiber Plates in .5, 1, 1.5, 2, 2.5, 3, 4 & 5mm thickness (up to 500 X 600mm). We can also special order other sizes and types of finishes. All Carbon Fiber edges are lightly wet sanded to clean them up after cutting.

We support CNC Carbon Fiber Cutting, shaped carbon fiber part, customized carbon fiber tube( curved carbon fiber tube, Octagon carbon fiber boom) and Logo Service.

Material: full carbon fiber plates sheets

Size: 400x500mm, 500X600mm, 600X800mm, 800X1000mm or other customized size

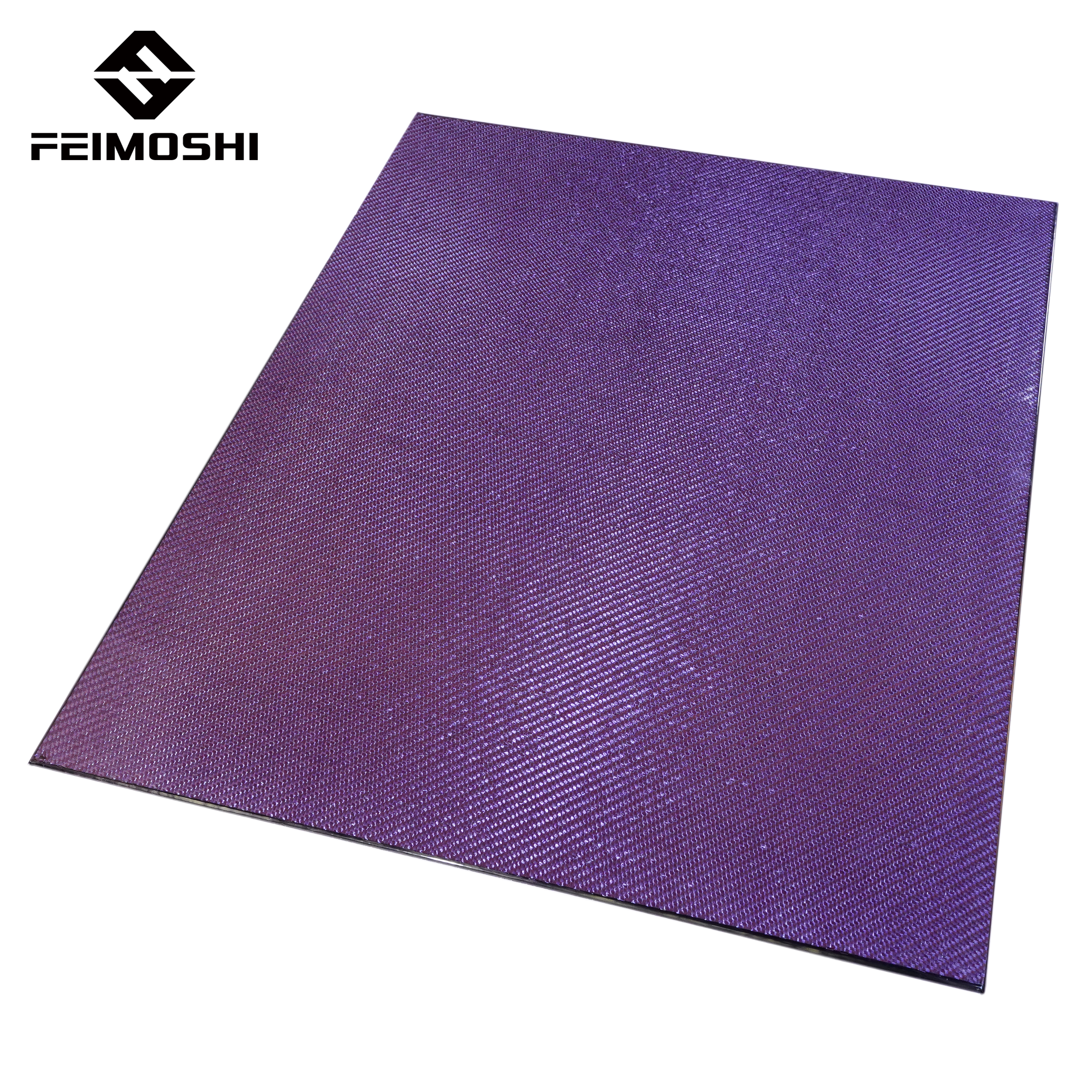

Surface: 3K/1K twill/Plain matt/Glossy

Stock: twill matte 0.5-10.0mm full carbon plates in stock

Service: OEM & ODM and CNC cutting services

Our service

* Drawings, photos and samples are welcome.

* We can produce the products as to your requirement or samples. Special for your own.

* Please contact us freely if there is any question.

* We are looking forward to have a good cooperation with you.

* Welcome to Hobby Carbon!

FAQ

Q:1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q: 2. What is the lead time?

A:Sample needs 1-3 days, mass production needs 10-15 days, also according to the order volume.

Q: 3. Do you have any MOQ limit?

A: Our MOQ is 200pcs for both formal raw material and processing parts.

Q: 4. Can you accept mixed batch of different products?

A: Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc

Q: 5. How do you ship the goods and how long does it take arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

Looking for ideal Carbon 3K Fiber Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the CNC Cutting Parts are quality guaranteed. We are China Origin Factory of Carbon Fiber CNC. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber was produced in the early 1950s in response to the needs of cutting-edge science and technology such as rockets, aerospace and aviation, and is now widely used in sports equipment, textiles, chemical machinery and medicine. With the increasingly stringent requirements of cutting-edge technology on the technical performance of new materials, scientific and technological workers are constantly striving to improve. In the early 1980s, high-performance and ultra-high-performance carbon fibers appeared one after another, which was another leap in technology, and also marked that the research and production of carbon fibers had entered an advanced stage. China Cheap price Composite Part - 3K carbon fiber CNC cutting parts – Feimoshi , The product will supply to all over the world, such as: Macedonia, Barbados, United States, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.