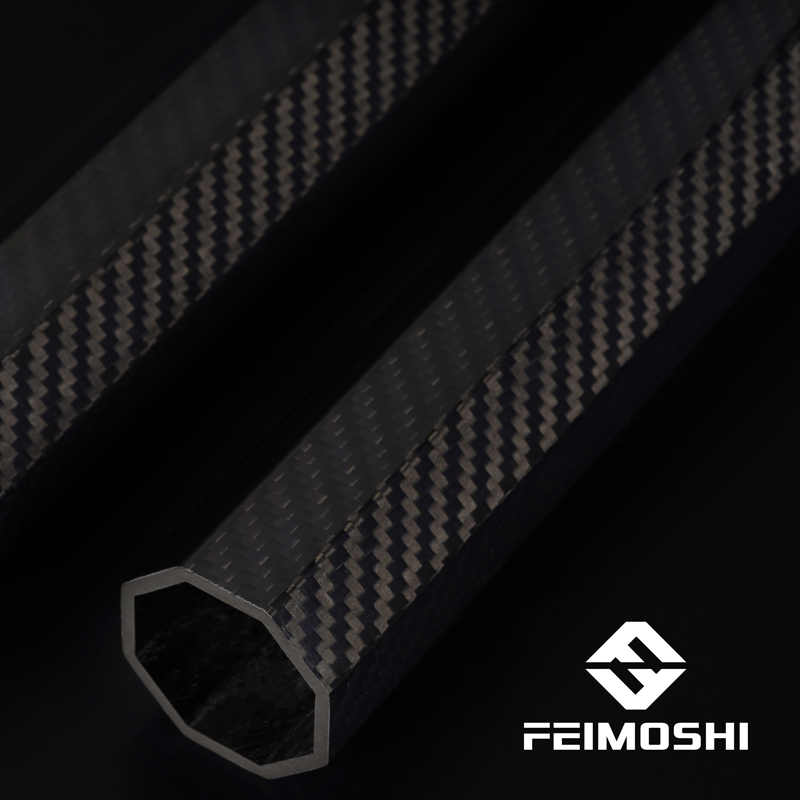

China wholesale Carbon Fiber Pipe - 30mm custom carbon fiber octagonal tube – Feimoshi

China wholesale Carbon Fiber Pipe - 30mm custom carbon fiber octagonal tube – Feimoshi Detail:

30mm custom carbon fiber octagonal tube

Carbon tube/pipe features:

1. Introduction

These 3K Octagonal Carbon Fiber Tubes Carbon are made of pure carbon fiber with beautiful twill or plain weave; Available in different colors and sizes( usually 3K twill matte); Customized Round tube specs are accepted, like Outer Diameter: 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 20mm, 22mm, 25mm, 30mm……350mm;

Customized Shaped Carbon Fiber Tube: such as: 20X30mm, 30X30mm or others. Thickness: 1.0mm, 1.5mm, 2.0mm or other thickness.

Length:

Recently we upgrade our machines to improve the carbon fiber tube precision.

Most precise tolerance shaped carbon fiber tubes for us.

2. Specifications

1) High temperature resistance carbon fiber tubes:100%carbon fiber ;

2) Light & high strength;

3) Good corrosion resistance;

After the use of carbon fiber drone components, not only the weight of the drone is reduced, but also the load, flight time and distance of the drone have been greatly improved. According to carbon fiber customer case analysis in recent years, the demand for carbon fiber pipes is mainly concentrated in the fields of unmanned aerial vehicles, automotive rail transit, industrial machinery, etc. The original intention of their applications is mostly lightweight.

Looking at the entire UAV market, we will find that lightweight is the most intuitive purpose, but ultimately, the performance of UAVs must be improved through lightweight. In fact, in addition to lightweight, because the linear expansion coefficient of carbon fiber materials is almost “0″, in some thermally sensitive areas, temperature changes will have a certain impact on measurement accuracy. High-end aerospace instruments need to pay special attention to this. The low creep of carbon fiber tubes can meet this demand.

Therefore, lightweight is the main purpose of the application of carbon fiber tubes, but it is not limited to this point. The physical and chemical properties of carbon fiber tubes are relatively excellent, and the ultimate goal is to achieve the overall performance of the equipment through it.

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal Carbon Fiber Pipe Cost Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fibre Tube 30mm are quality guaranteed. We are China Origin Factory of Carbon Fiber Charge Pipe. If you have any question, please feel free to contact us.

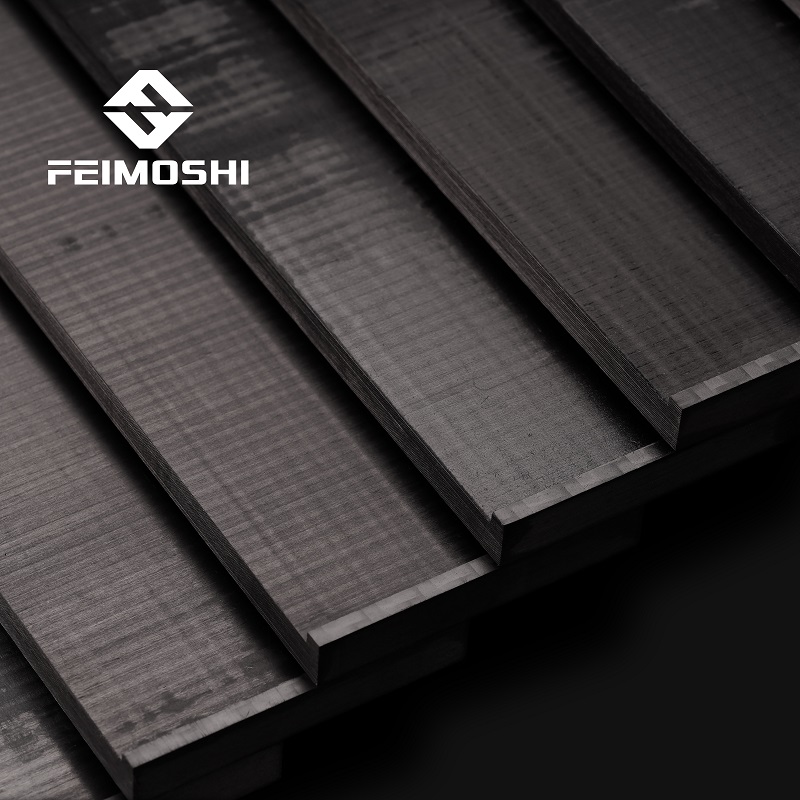

Product detail pictures:

Related Product Guide:

Carbon fiber is made of man-made fiber with high carbon content and does not melt during the whole process of heat treatment, and is made by thermal stable oxidation treatment, carbonization treatment and graphitization. In today's economic and social development, carbon fiber has long been widely used as a new material, ranging from aerospace industry equipment raw materials to small handbags and other fields. So why is carbon fiber so popular? What are its actual advantages? China wholesale Carbon Fiber Pipe - 30mm custom carbon fiber octagonal tube – Feimoshi , The product will supply to all over the world, such as: Sri Lanka, Irish, Porto, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.