Factory Cheap Hot Drill Composite Boom - CNC Cutting 3K Carbon Fiber Sheet Plates – Feimoshi

Factory Cheap Hot Drill Composite Boom - CNC Cutting 3K Carbon Fiber Sheet Plates – Feimoshi Detail:

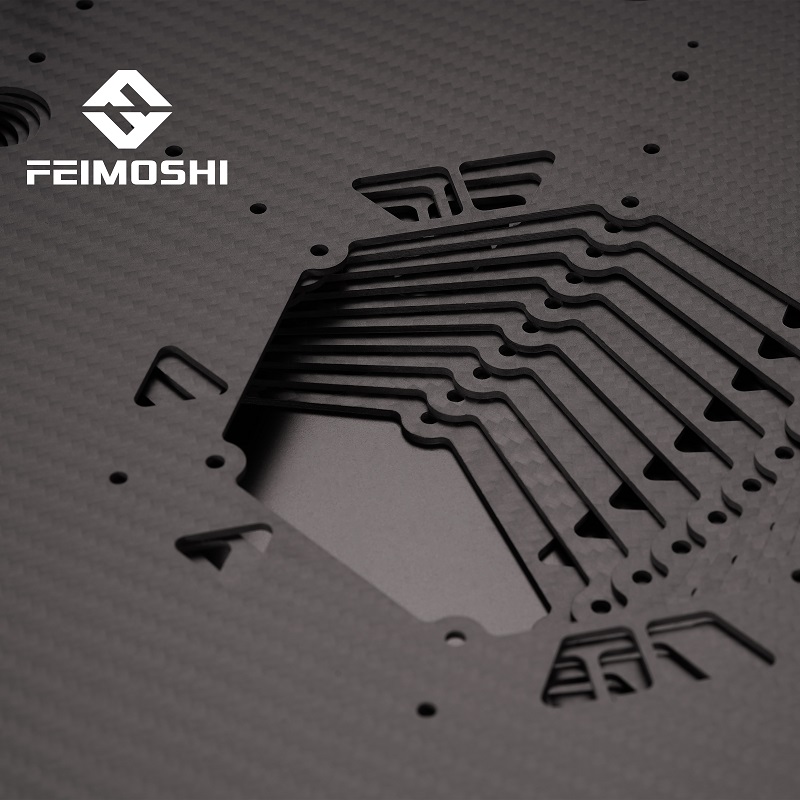

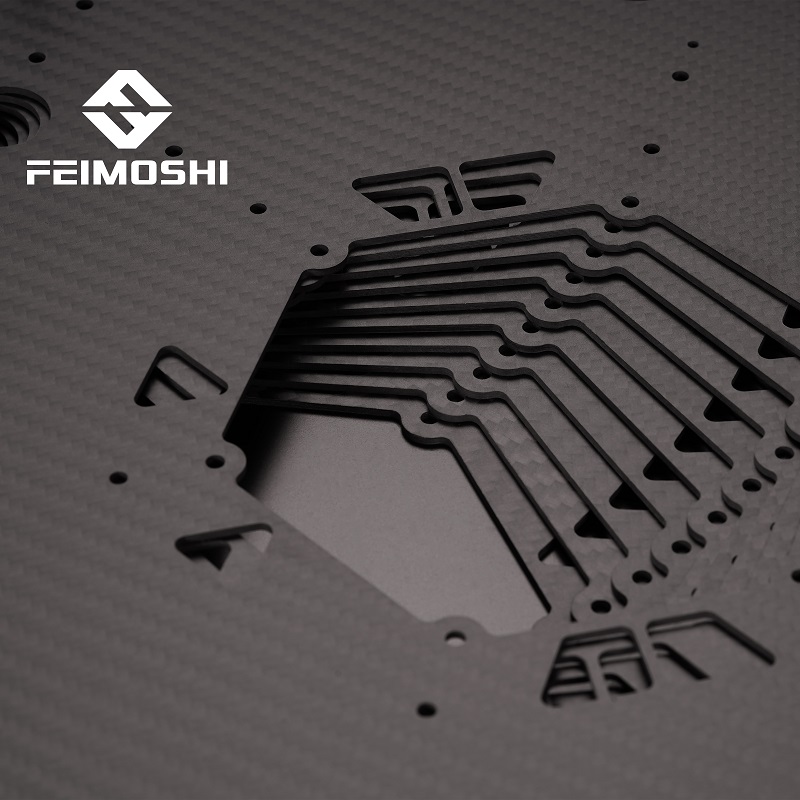

CNC Cutting 3K Carbon Fiber Sheet Plate

CNC Carbon Fiber Cutting is a special way to help customers get the unique frame to produce their drones in the market. We made many cooperation with many popular brand and also get more and more good feedback.

More quantity, more competitive price for your FPV frame.

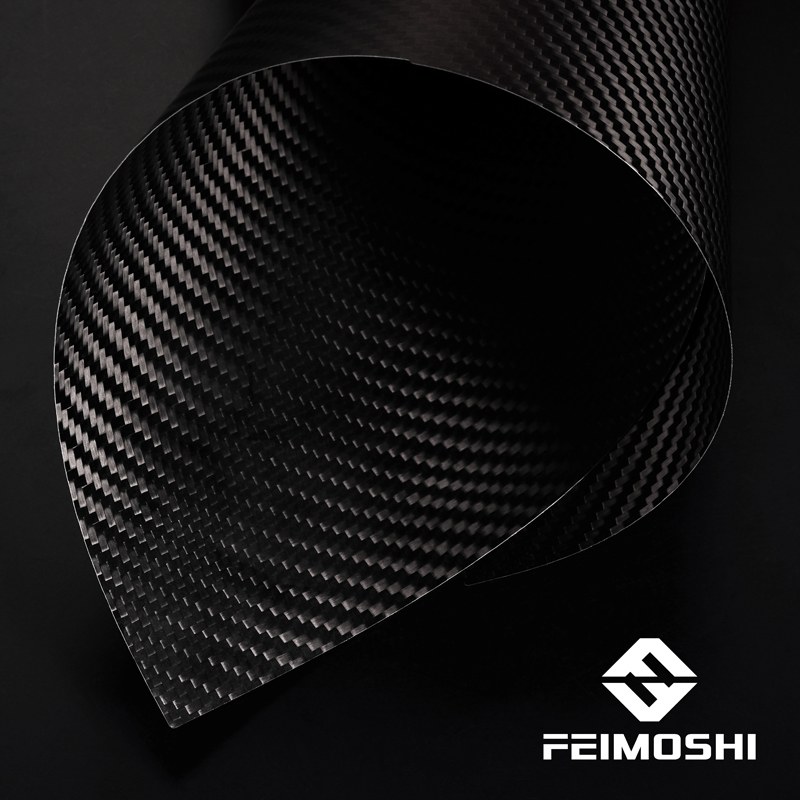

We produced the carbon fiber plate by the carbon fiber cloth.

Carbon fiber cloth is similar to cloth, light in weight, thin in thickness, and soft in texture. It can be cut at will and is woven from carbon filaments. The thickness of carbon fiber cloth is 0.167mm for 300g and 0.111mm for 200g. It is suitable for the treatment of increasing building load, changing the function of engineering use, material aging, concrete strength grade lower than the design value, structural crack treatment, service component repair and protection in harsh environments. And it can greatly help the structure in terms of shear resistance, seismic resistance and bending resistance. In use, it can be pasted in multiple layers according to engineering design requirements. It is recommended that no more than 4 layers are used. Because carbon fiber is posted in multiple layers at the same time, the tension attenuation will cause waste.

Looking for ideal Carbon Fiber 10mm Plate Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 3K Carbon Fiber Sheet Plate are quality guaranteed. We are China Origin Factory of Carbon Fiber 60 Keyboard Plate. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. Factory Cheap Hot Drill Composite Boom - CNC Cutting 3K Carbon Fiber Sheet Plates – Feimoshi , The product will supply to all over the world, such as: Israel, America, Singapore, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.