Factory Supply Cnc Laser Cutting - New Kevlar fiber iPhone 13mini, iphone 13, phone 13 pro & 13 pro max Case – Feimoshi

Factory Supply Cnc Laser Cutting - New Kevlar fiber iPhone 13mini, iphone 13, phone 13 pro & 13 pro max Case – Feimoshi Detail:

WHAT IS KEVLAR?

Kevlar is a flexible, heat resistant material made of strong and synthetic fibers.

It’s durable nature makes it a go-to choice for aerospace and military applications.

FORM FITTING

Our Kevlar Case is designed to be form-fitting, yet durable for everyday use. The non-conductive and pliable nature makes it the perfect phone protector.

The Aramid Shield is made from 100% aerospace-grade 600D ARAMID FIBER which is ultra-durable, lightweight, and scratch-resistant.

Used by the military Aramid offers unparalleled protection for your iPhone 12 Pro Max |

Weighing in at only 7-10g

the AramidShield is a true featherweight

With its low-profile and sleek carbon fiber look this case truly stands out

Experience the NO CASE FEELING

Precision cut-outs to all ports, speakers, and openings

ENLARGED CHARGE PORT CUT-OUT allowing you to fit most third-party chargers

Easy SNAP-ON & SNAP-OFF DESIGN

Perfectly RAISED LIPS for smooth swipe & gesture action

FULL CONNECTIVITY with no signal, Wifi or GPS interference

Wireless Charging Compatible

The Aramid Shield allows enough space for most third-party tempered glass screen protectors

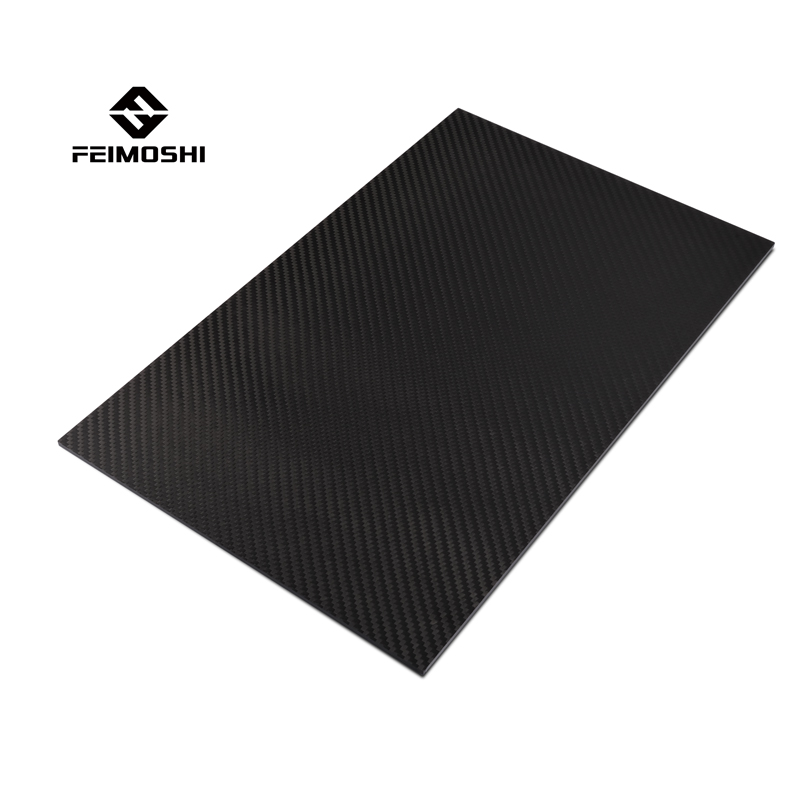

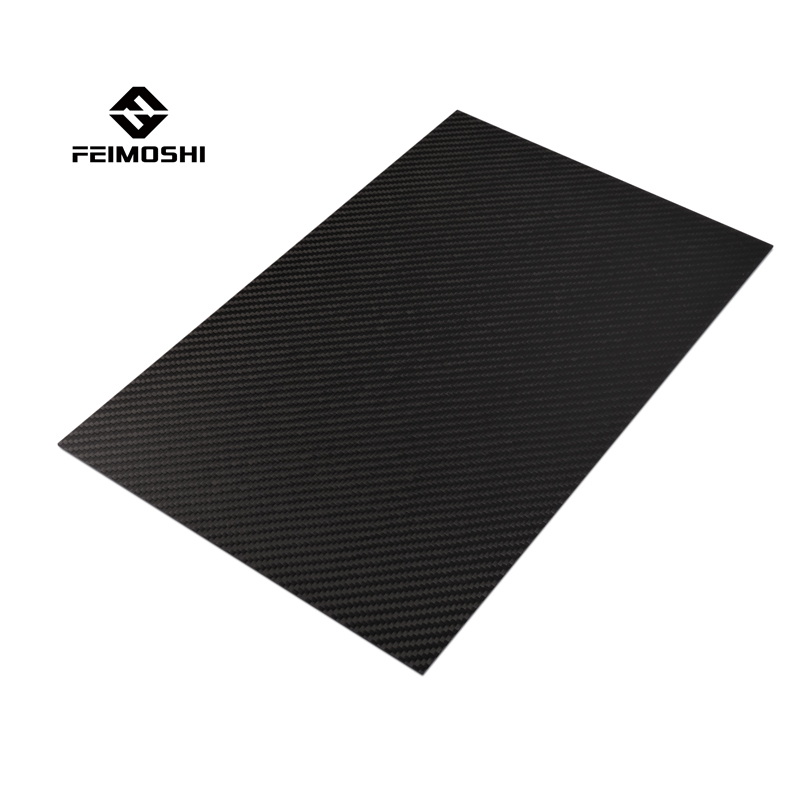

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. Factory Supply Cnc Laser Cutting - New Kevlar fiber iPhone 13mini, iphone 13, phone 13 pro & 13 pro max Case – Feimoshi , The product will supply to all over the world, such as: Lahore, Rio de Janeiro, Benin, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!