Factory wholesale Making Carbon Fiber Sheets - Rc racing carbon fiber cutting plate – Feimoshi

Factory wholesale Making Carbon Fiber Sheets - Rc racing carbon fiber cutting plate – Feimoshi Detail:

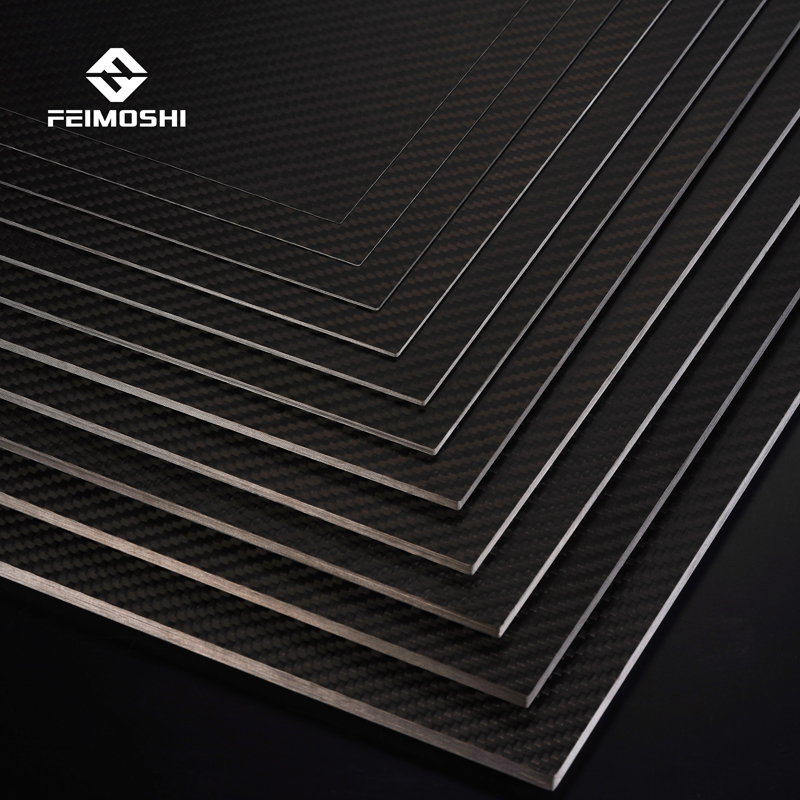

Rc racing carbon fiber cutting plate

Description

Carbon fiber sheets are widely used in our daily life. It could be cut in any shape. We have plain and twill weave for our customers choose.

Our regular size is 400x500mm and 500x600mm. And our biggest size is 20000x1500mm. Customize other sizes also is ok. The thickest carbon fiber plate that we can do is 20mm.

Among them, the best size we sell is a 400x500x2.0mm board.

If any interested, welcome to send an inquiry to us.

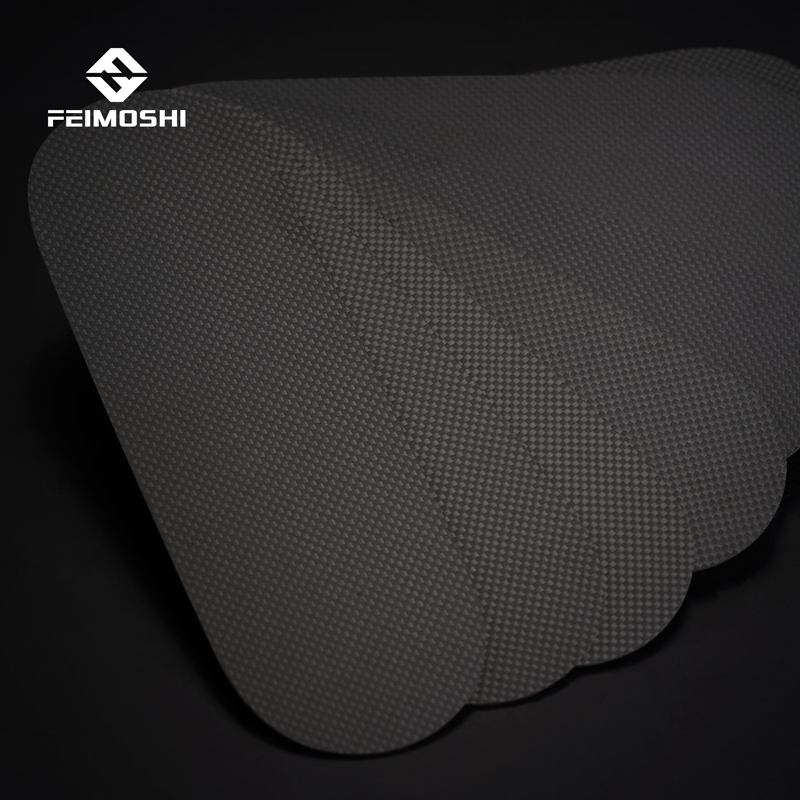

Special Process

Some of our customers will add some special process to the carbon fiber frame to make their carbon parts look better. (such as add countersunk face, countersunk hole, chamfer)

Product detail pictures:

Related Product Guide:

The basic properties of chopped carbon fiber are mainly inherited from its raw material, continuous carbon fiber. What kind of continuous carbon fiber is used as the raw material also directly determines the price of chopped carbon fiber. The tensile strength of continuous carbon fibers directly affects the tensile properties of chopped carbon fiber composite thermoplastics. Some chopped carbon fiber manufacturers will mix different types of continuous carbon fibers due to insufficient raw material supply or cost issues, but this will lead to unstable properties of chopped carbon fiber composite thermoplastic materials. Therefore, when purchasing chopped carbon fiber, it is best to ask the supplier to indicate the type or main performance of continuous carbon fiber on the quality inspection sheet. Factory wholesale Making Carbon Fiber Sheets - Rc racing carbon fiber cutting plate – Feimoshi , The product will supply to all over the world, such as: Ghana, Cannes, Nicaragua, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Send your message to us:

Write your message here and send it to us