Fast delivery Carbon Fiber Battery Brace - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi

Fast delivery Carbon Fiber Battery Brace - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi Detail:

Lightweight phone case carbon fiber shockproof and anti-drop

Below is the newest iPhone 13 cases:

1. Material: Kevlar Fiber

2. Technology: Vacuum Pumping by Autoclave equipment

3. Weight: as light as you thought

4. MOQ: 10pc

5. Matte surface, no sweats, no fingerprints;

6. 4-side protection, camera lens protection;

7. Excellent grip, no loose;

8. 1:1 precise cutouts for ports and buttons;

9. Like a skin, keep the original beauty/feeling of the device

Why do we use aramid fiber, but don’t use carbon fiber?

Aramid fiber is commonly used in aerospace and performance automotive industries, as it is exceptionally durable and lightweight.

Different from carbon fiber, aramid fiber does not affect your phone’s signal (Wi-Fi, GPS, and cell reception), making it the ideal material for phone cases.

Using vacuum forming technologies, we can mold aramid fiber into a multitude of designs while maintaining its strength and protective qualities.

Product detail pictures:

Related Product Guide:

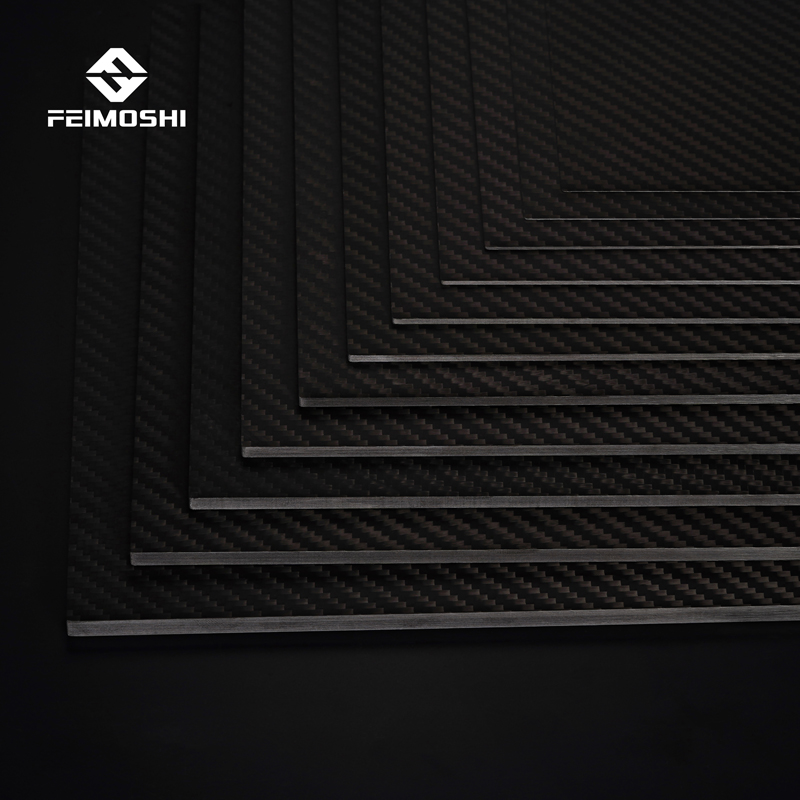

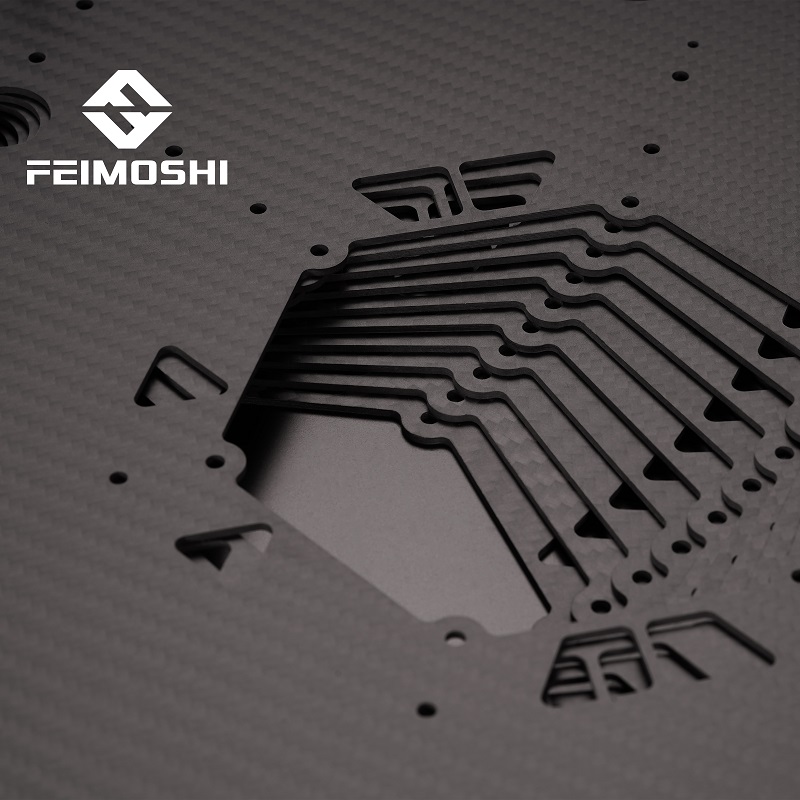

Carbon fibers are generally not used alone, but in the form of composite materials. Composite material refers to a new type of material with certain special functions and structures formed by combining two or more materials. The material composition can be generally understood as matrix material + reinforcement material, among which the matrix material is mostly resin, ceramic, metal, Rubber and other materials, the reinforcing material is often glass fiber or carbon fiber. Fast delivery Carbon Fiber Battery Brace - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi , The product will supply to all over the world, such as: Danish, Ottawa, Finland, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!