Good quality 20mm Carbon Fiber Plate - OEM service custom carbon fiber cnc cutting – Feimoshi

Good quality 20mm Carbon Fiber Plate - OEM service custom carbon fiber cnc cutting – Feimoshi Detail:

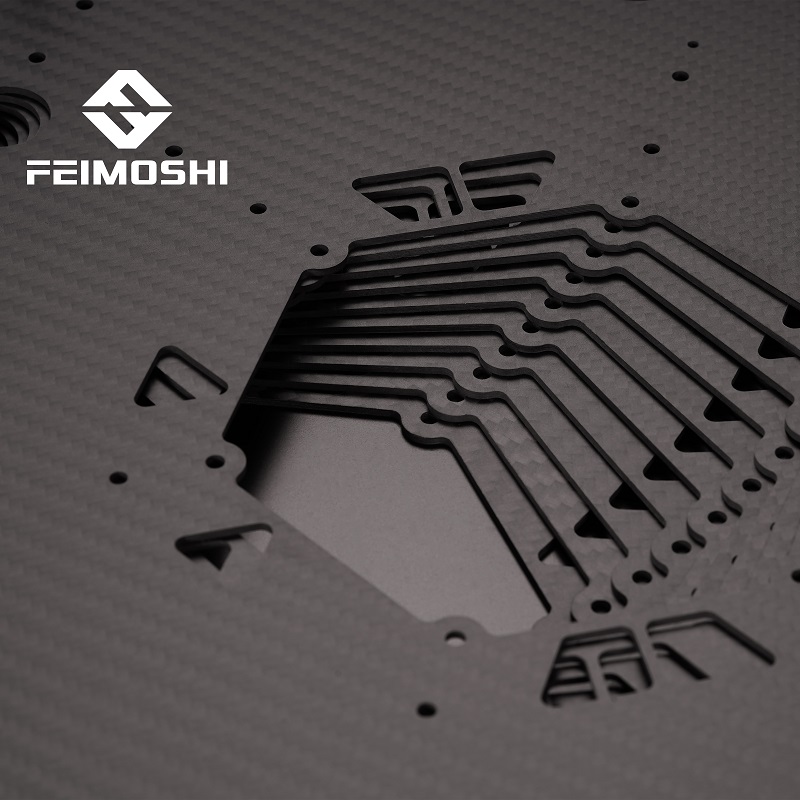

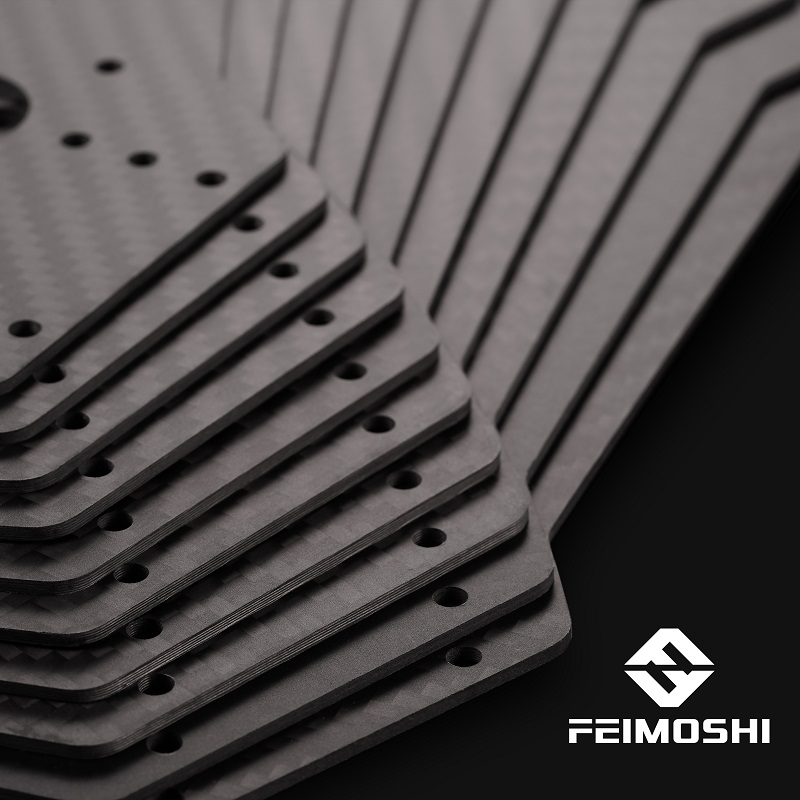

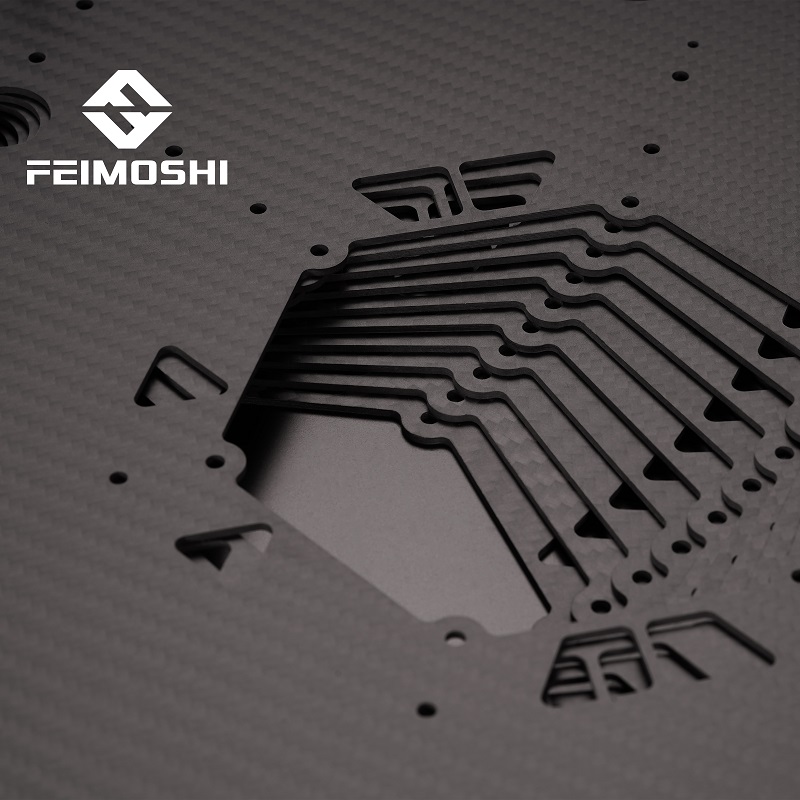

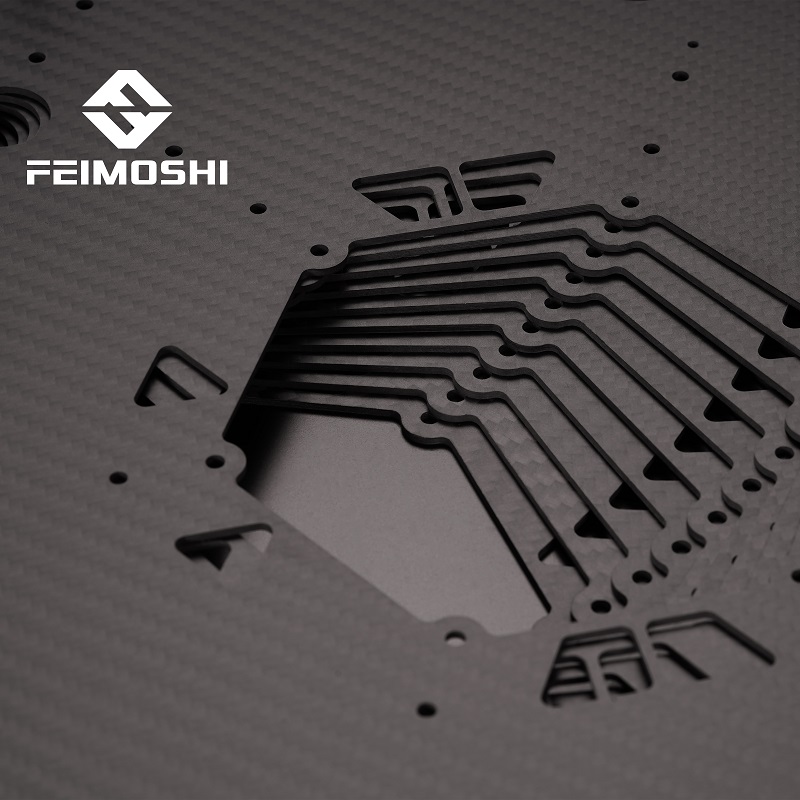

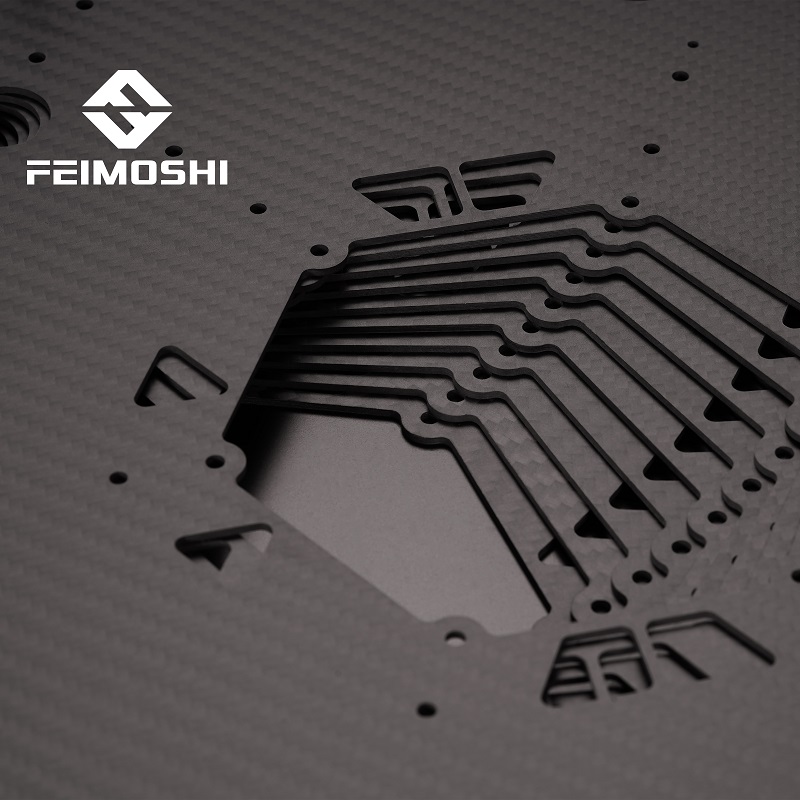

OEM service custom carbon fiber cnc cutting

Carbon fiber plates come in so many variations to fit a wide range of applications. A standard carbon fiber plate is an excellent replacement for aluminum plates when you need something lightweight and strong.

Carbon fiber plate comes in thicknesses from 0.040” (1mm) up to 1.00” (25.4mm) to fit nearly any application. Standard twill and plain weave plates are excellent choices for replacing aluminum or steel.

Material: carbon fiber frame part

Size: Customized (welcome to customized)

Surface: Twill/Plain Matte/Glossy or other colors

Stock: Normal plates are in stock

Service: OEM & ODM, Cnc Cutting Service, And Logo Printing

Other Service: Packing and assembly service

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is the Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for tesing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing

Product detail pictures:

Related Product Guide:

Carbon fiber tubes are mainly used in drone body parts, industrial machinery rollers, intelligent mechanical telescopic arms, camera follow focus slides, medical equipment parts, astronomical telescope parts, high-speed gate landing rods, temporary support rods, sports sports Equipment and other industries. Our company has more than ten years of production and processing experience in the carbon fiber industry, and can help you realize the large-scale production of carbon fiber products according to your needs and production requirements. Good quality 20mm Carbon Fiber Plate - OEM service custom carbon fiber cnc cutting – Feimoshi , The product will supply to all over the world, such as: India, Ghana, Leicester, Carbon fiber board mainly has the following characteristics:1. Light weight and high toughness. The weight of carbon fiber board is similar to that of plastic of the same volume, which is 20% of that of steel. Although it is light, its toughness is comparable to that of steel. It can be bent and coiled.2. High tensile coefficient. The tensile coefficient of carbon fiber is several times higher than that of steel, and it has good resistance to deformation, so carbon fiber boards are used in concrete reinforcement, bridge reinforcement and other places.3. Good chemical stability. Carbon fiber board base material is carbon element, carbon element has good chemical stability, and has the characteristics of corrosion resistance, acid and alkali resistance, wear resistance and so on.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.