Good Quality Carbon Fiber Sheet - Cnc Cutting Carbon Fiber Sheet Composite sheet – Feimoshi

Good Quality Carbon Fiber Sheet - Cnc Cutting Carbon Fiber Sheet Composite sheet – Feimoshi Detail:

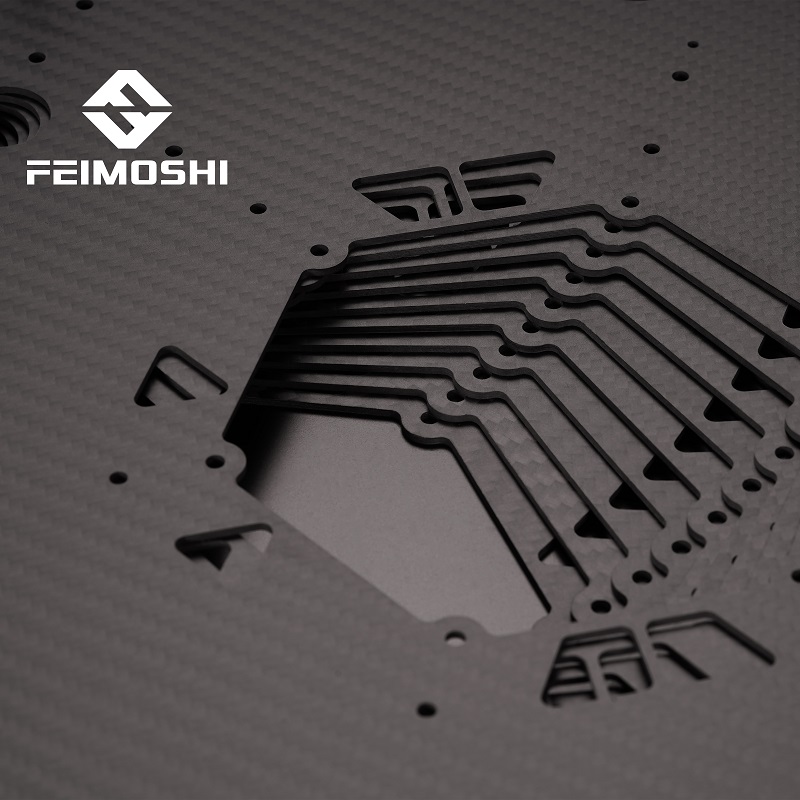

Cnc Cutting Carbon Fiber Sheet Composite sheet

Description:

We use CNC machine to cut the carbon fiber. so the tolerance is precise, it could reach about +/-0.1mm.

Besides normal cutting, we also could do other special processes. such as do the chamfer in the edges, add the countersunk hole or countersunk face, etc.

Main keyword: cnc carbon fiber cutting

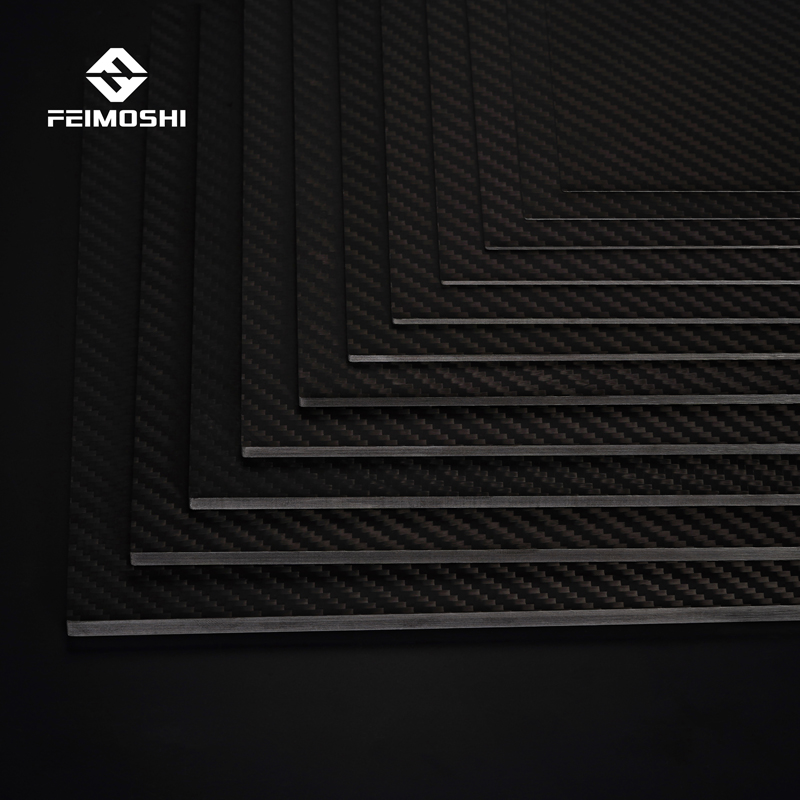

Thickness: 0.3mm-20mm

Service: CNC cutting service, logo service, customize service and so on

Surface: Glossy or matte

Weave: Plain and twill

FAQ

1. Professional manufacturer for carbon fiber sheet, carbon fiber tube, carbon fiber cutting parts, etc.

2. More than 10 years experience,you will get pleased service on time.

3. 100% inspection on critical dimensions with high accuracy +/-0.02-0.1mm

4. Factory direct price and fast delivery on time

5. Sample is available

6. OEM&ODM orders are welcome

*Drawings, photos and samples are welcome.

*We can produce the products as to your requirement or samples.Special for your own.

* please conact with us freely if there is any question.

*We are looking forward to have a good cooperation with you.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Good Quality Carbon Fiber Sheet - Cnc Cutting Carbon Fiber Sheet Composite sheet – Feimoshi , The product will supply to all over the world, such as: Norwegian, Lahore, Latvia, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.