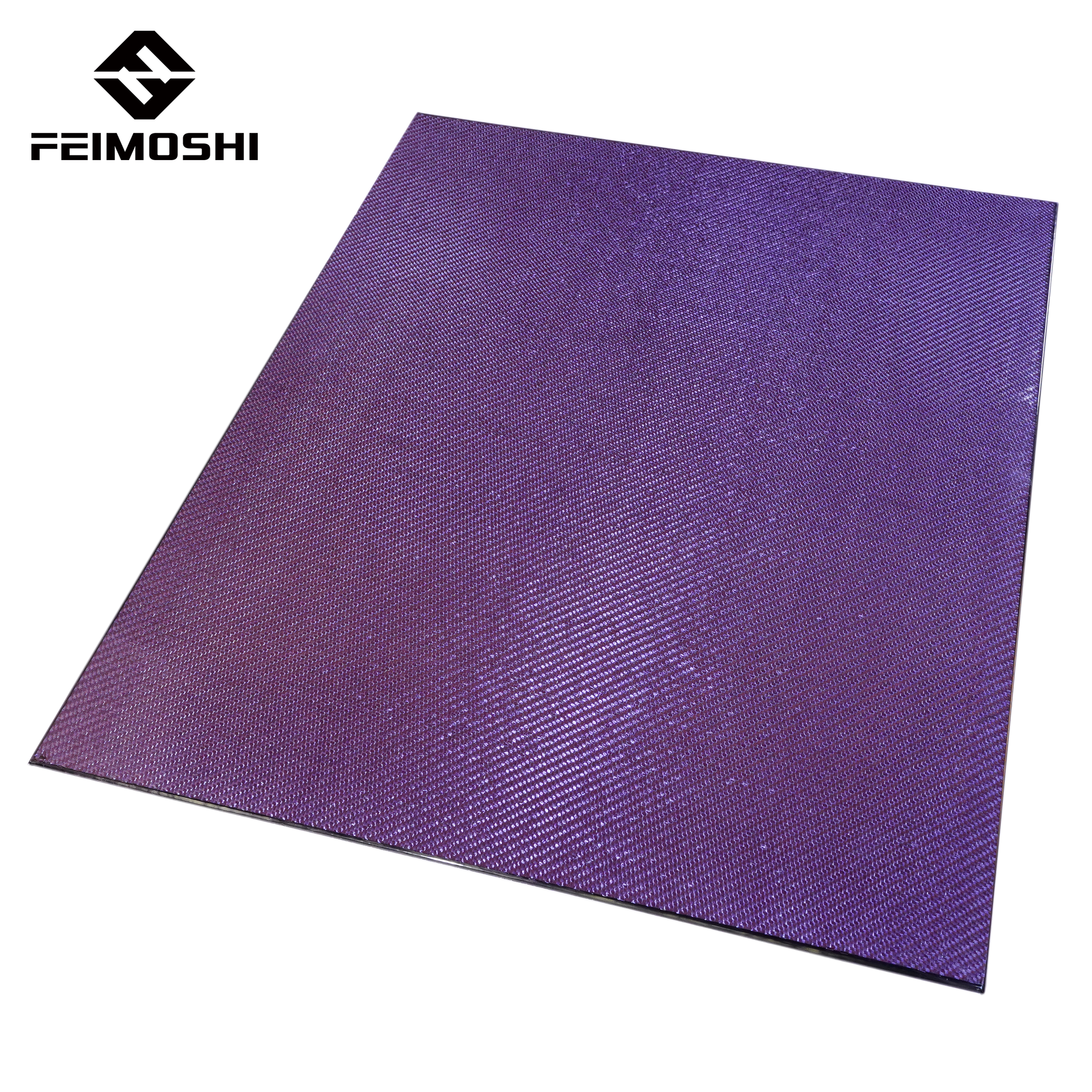

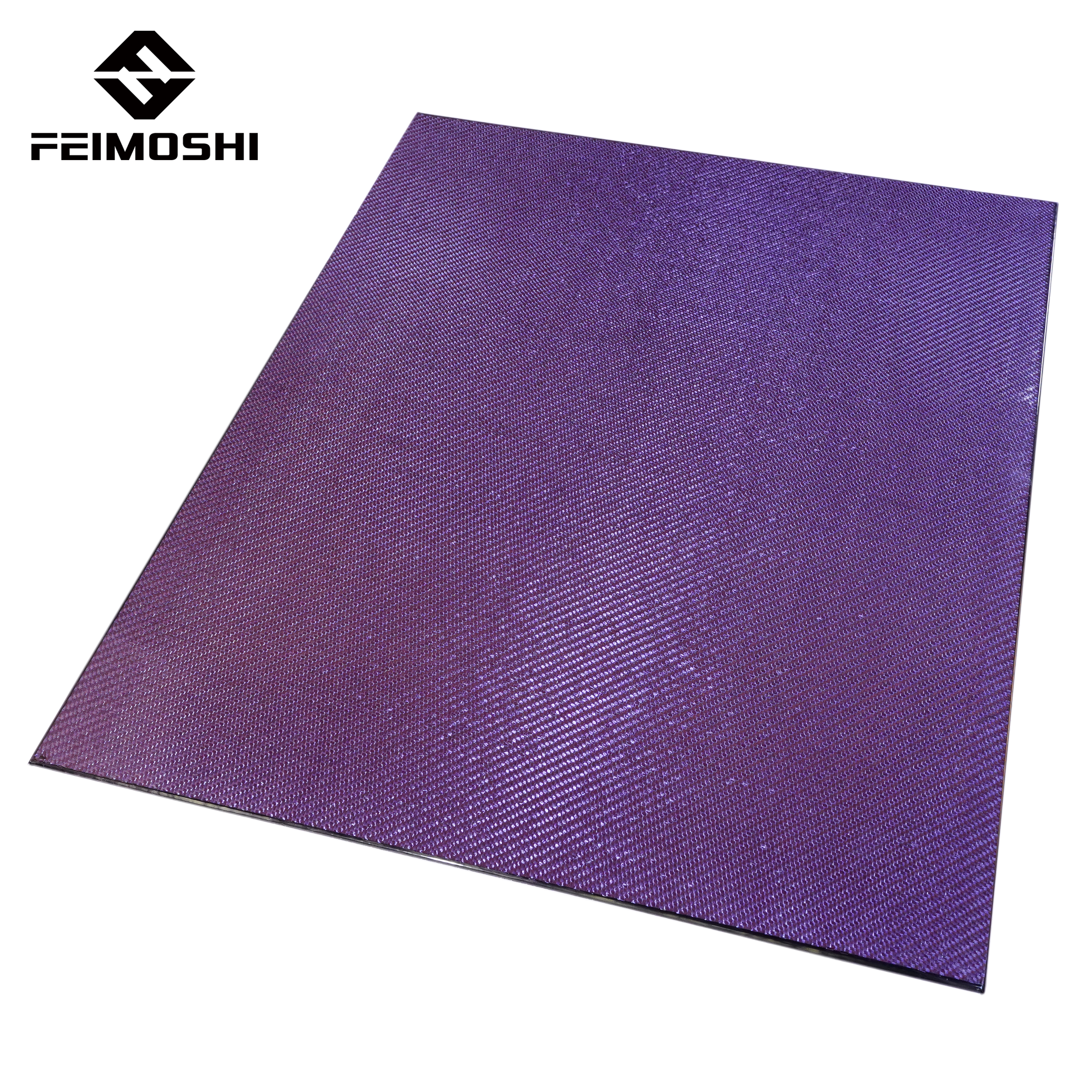

Good Quality Carbon Fiber Sheet - Purple 3K twill matte carbon fiber sheets for drone – Feimoshi

Good Quality Carbon Fiber Sheet - Purple 3K twill matte carbon fiber sheets for drone – Feimoshi Detail:

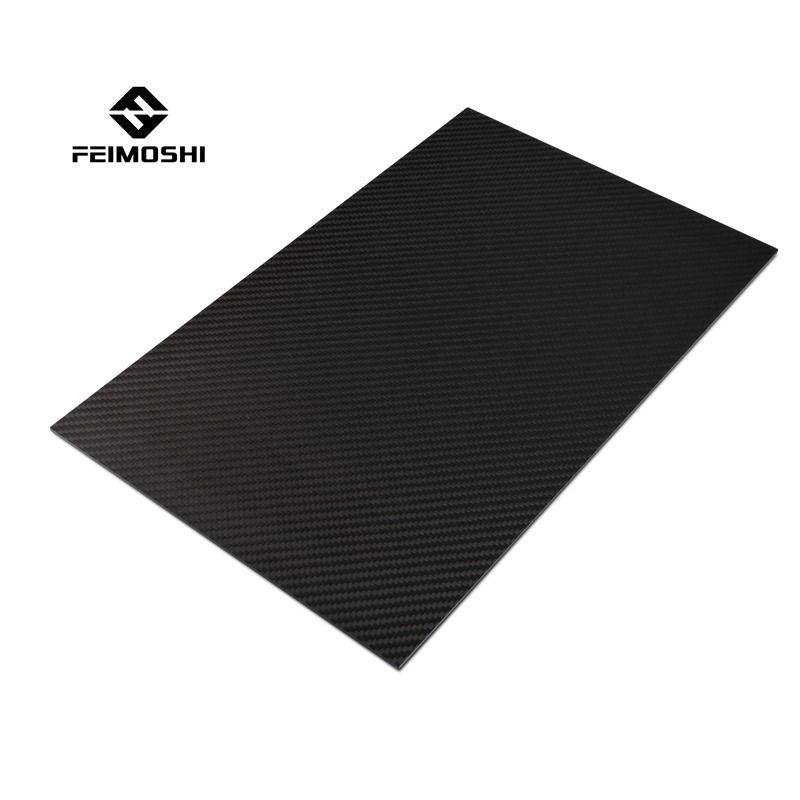

The carbon fiber board produced by our company has a 2×2 twill weave pattern, which is one of the most common weave patterns in many markets. The finished surface of the board has a classic 2×2 twill, 3K woven carbon fiber appearance, almost no pinholes, and high gloss.

The composite panels made of our high-strength vacuum autoclave are made of 100% carbon fiber and reinforced by a nearly transparent epoxy resin matrix. All composite material stacks are laid by hand to ensure maximum homogenization of the fiber arrangement. The stack is then vacuum infused and cured under a pressure greater than 28 inches of mercury. The tool is then raised to the optimum temperature to produce a nearly perfect composite board with advanced mechanical properties and A-level surface finish.

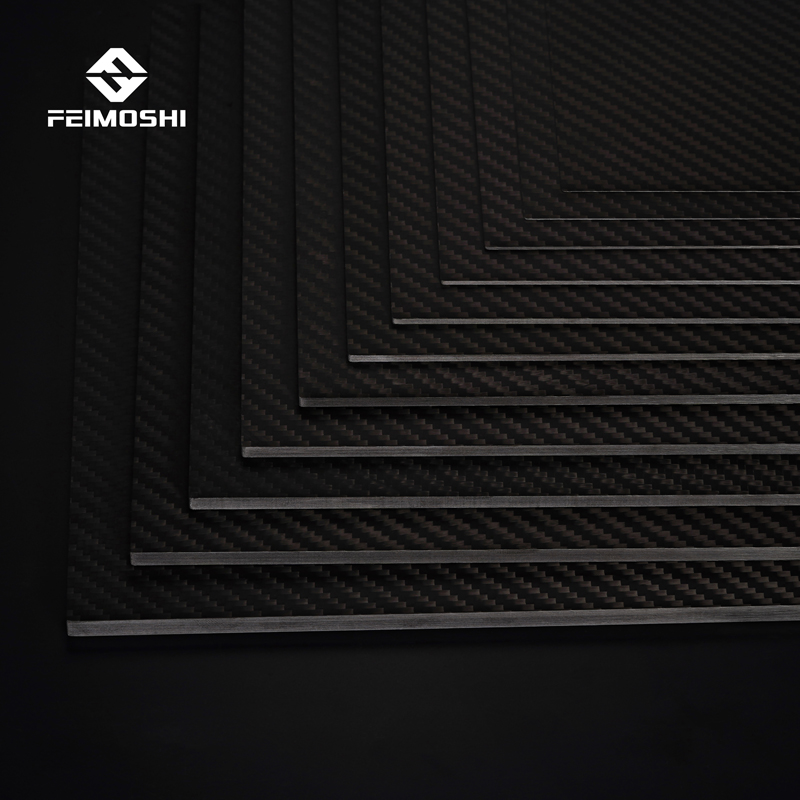

Laminated structure

To ensure the maximum structural integrity and flatness of all our panels, we produce “balanced” laminates for all panel thicknesses and dimensions. This means that the fiber type, weight, and weave pattern are symmetrical in all layers of the composite stack.

Plates of 1.4 mm/1/16 inch or thicker are quasi-isotropic laminates, made of non-woven, non-crimped carbon fiber layers, with orientations of 0º/90º/+45º/–45º. The orientation of the quasi-isotropic ply leads to the most uniform strength distribution and enhances torsional stiffness and diagonal stiffness.

Cross-stacking will produce boards with higher structural integrity, which may be required for many applications. The laminate stacking and laminate direction can be adjusted for specific applications; for example, if you need more board strength in a specific direction, but want to avoid adding extra laminate weight.

A detailed list of laminates and fabric stacks can be requested for each of our boards. Please specify the board model when inquiring.

Epoxy resin: All carbon fiber boards are made of high-performance epoxy resin, which has excellent mechanical functions, transparency and higher UV stability. An elevated post-curing temperature is applied to increase the mechanical strength of the board, which results in a higher Tg and enhances the interlaminar shear strength.

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. Good Quality Carbon Fiber Sheet - Purple 3K twill matte carbon fiber sheets for drone – Feimoshi , The product will supply to all over the world, such as: Serbia, Nigeria, US, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly