High definition Aluminum Composite - CNC machining carbon fiber parts cutting for drone – Feimoshi

High definition Aluminum Composite - CNC machining carbon fiber parts cutting for drone – Feimoshi Detail:

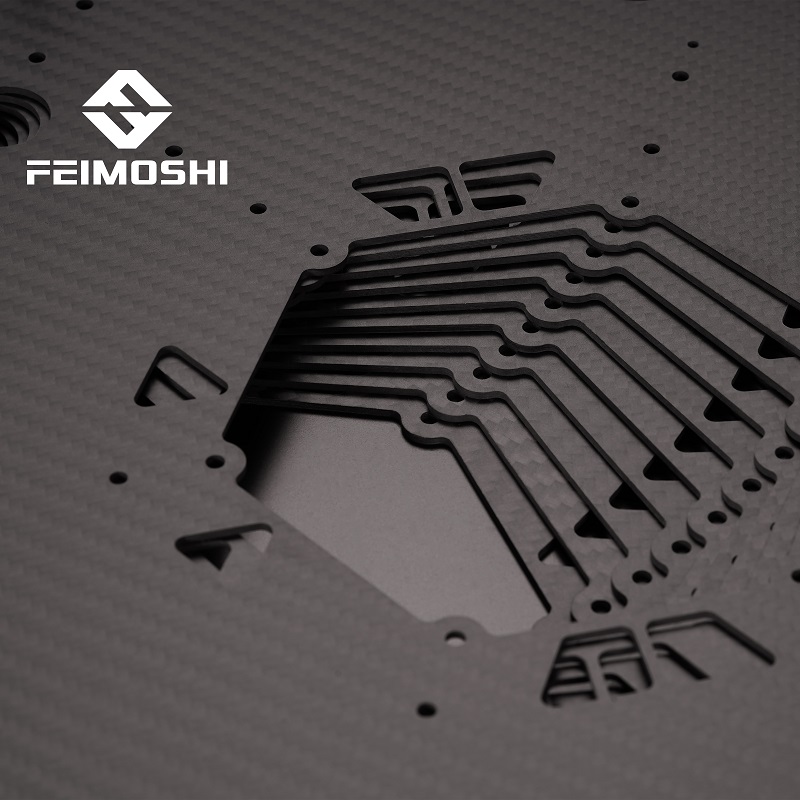

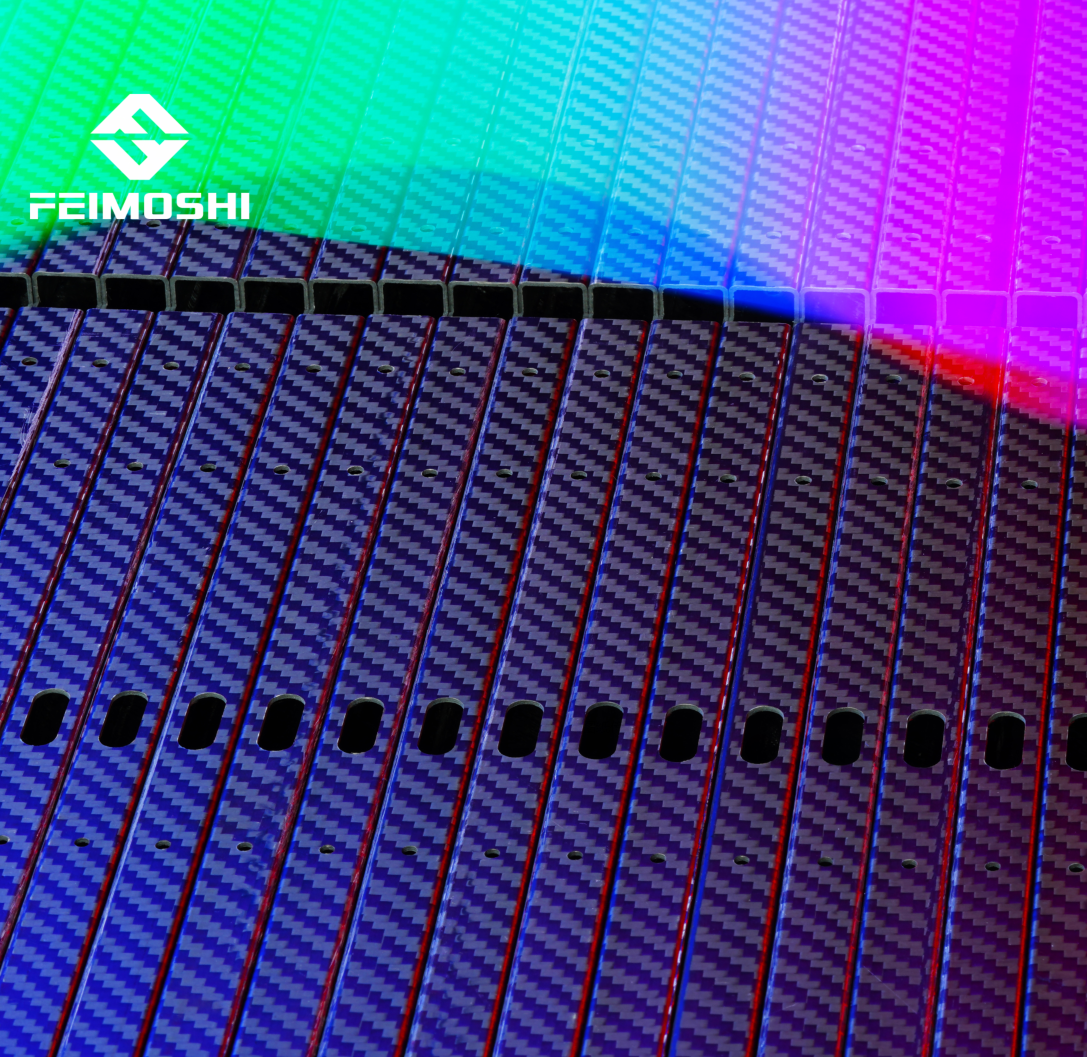

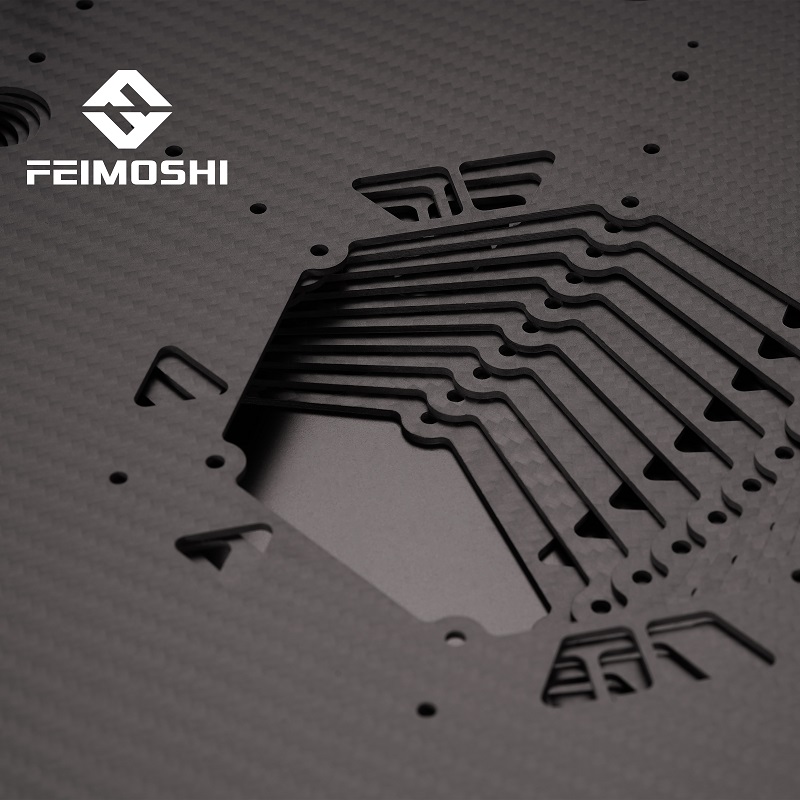

CNC machining carbon fiber parts cutting for drone

FEIMOSHI is a proffessional manufacturer of carbon fiber products, loved by drone customers and our CNC cutting process has won their praise. CNC machining is precision and cost-effective way to achieve innovation and creativity, which triggers out our endless imagination and creative inspiration. We had made so many different carbon fiber CNC parts for racing parts, RC helicopters, bicycle bracket, and reinforcements for 10 years.

Feature:

Surface: Matter/Light/Twill/plain

Size: OEM(STEP, DWG or other)

Material: 100% carbon fiber

Shape: Smooth

Technical: FPV/Drone/UAV/RC Frame

Applications:

1. Aerospace, Helicopters Model Drone ,UAVS, FPV

2. RC model parts

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

9. building construction repair and strengthening

Our service

Any needs, please feel free to contact me!

Express: Fedex, UPS, DHL, TNT

Delivery time: about 5-10 working days

After-sales service

Product detail pictures:

Related Product Guide:

Carbon fiber tube is one of the more common application forms of carbon fiber composite materials in industrial, civil, medical and other fields. Due to its advantages of light weight, high strength and flexible design, it has the development trend of becoming a new generation of parts and components. High definition Aluminum Composite - CNC machining carbon fiber parts cutting for drone – Feimoshi , The product will supply to all over the world, such as: Botswana, Egypt, Niger, Carbon fiber tube, also known as carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated and cured by pultrusion (twisting).Carbon fiber tubes have the advantages of high strength, long life, corrosion resistance, light weight and low density, and are widely used in kites, aircraft models, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, small thermal expansion coefficient, self-lubrication, energy absorption and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance and so on. The advantage is that it has very good tensile strength (for example, calculated in units of 12,000 filaments, its tensile strength is kg/mm2—400).

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!