High definition Composite Plate Fit - Carbon Fiber-Reinforced full twill matte or glossy 3K carbon fiber plate – Feimoshi

High definition Composite Plate Fit - Carbon Fiber-Reinforced full twill matte or glossy 3K carbon fiber plate – Feimoshi Detail:

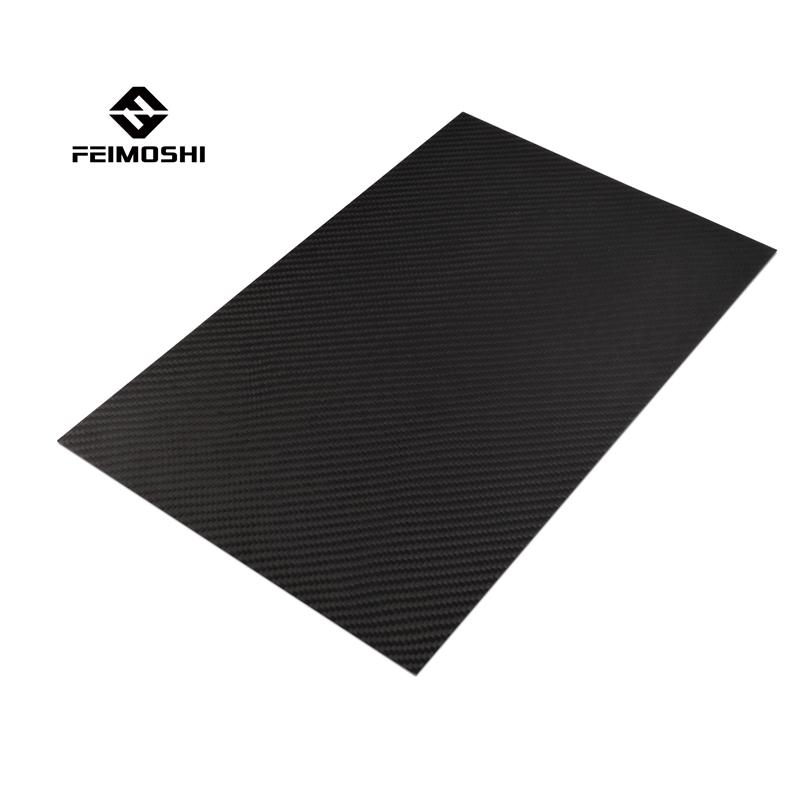

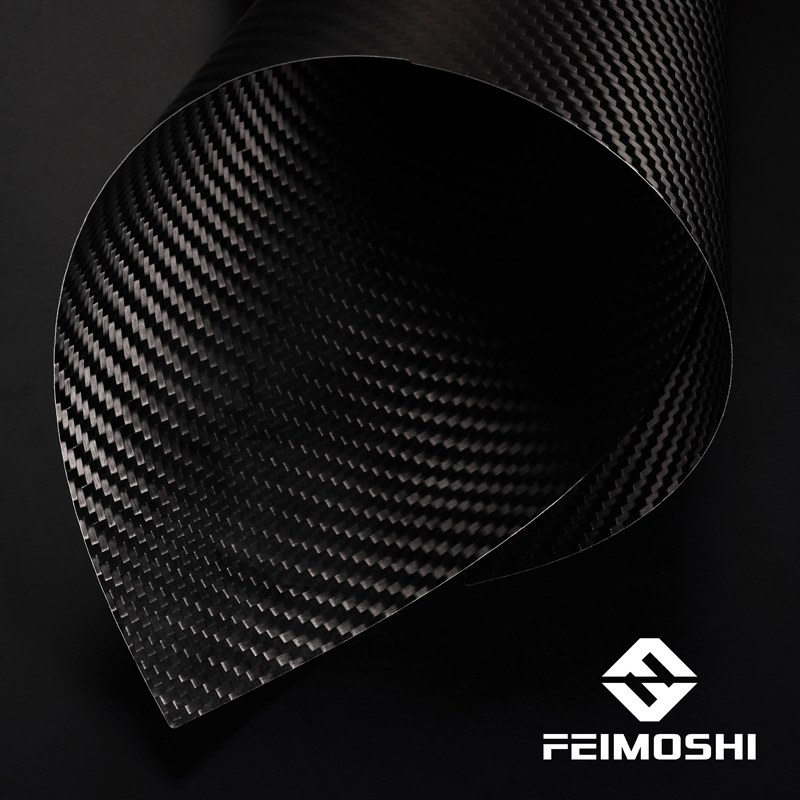

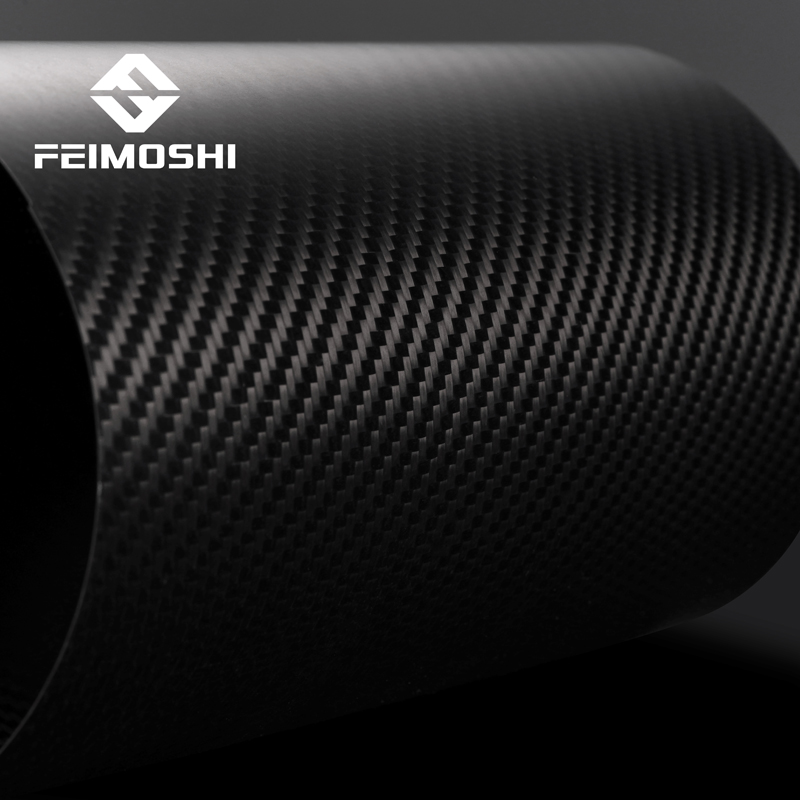

Carbon Fiber-Reinforced full twill matte or glossy 3K carbon fiber plate

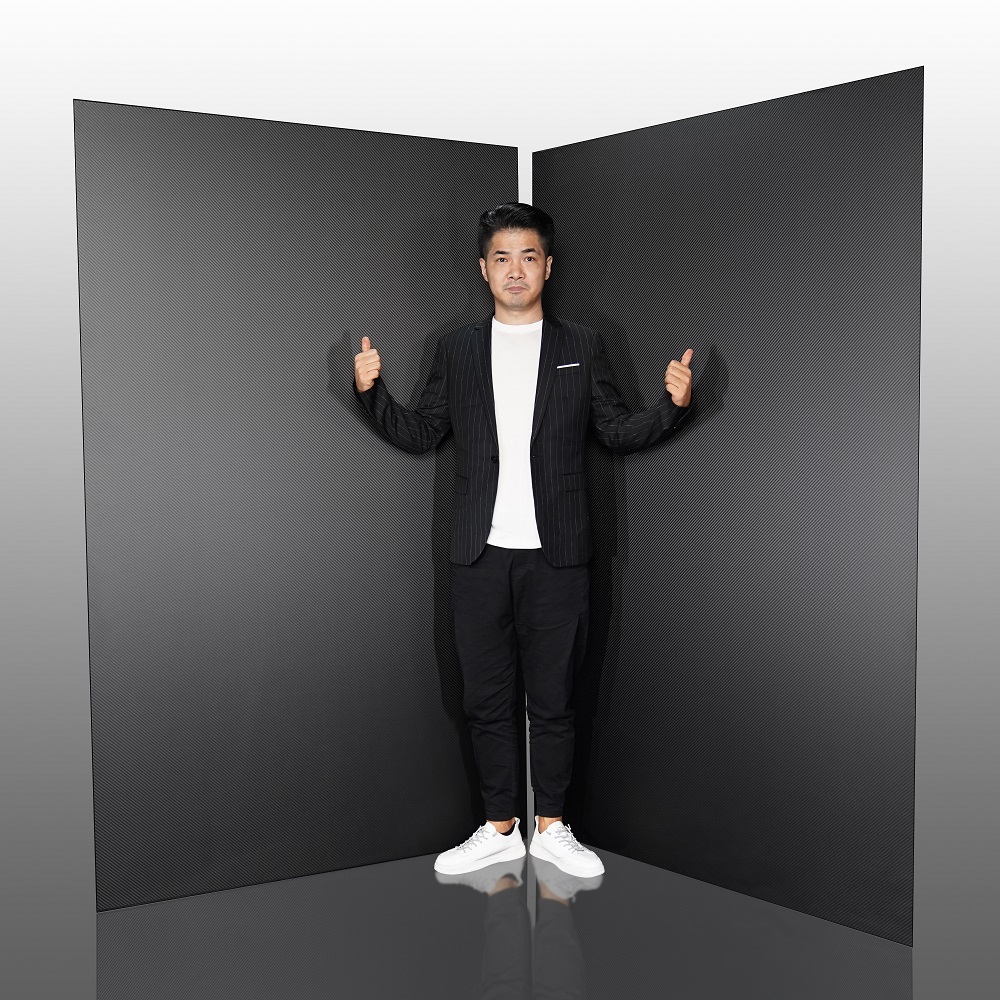

Carbon fiber plates are made from high quality carbon fiber material, our carbon fiber sheets panels are durable, high quality and affordable.

Feature

Material: 100% carbon fiber

Thickness: about 0.3-30mm

Surface: 3K Plain / 3K Twill / Unidirection

Size: 400*500/500*600mm

Payment Type: T/T, Paypal, Western Union

Incoterm: EXW

Min. Order: 3piece

Delivery Time: 10-15 working Days

Transportation: DHL/Fedex/TNT/Epacket

Port: Shenzhen

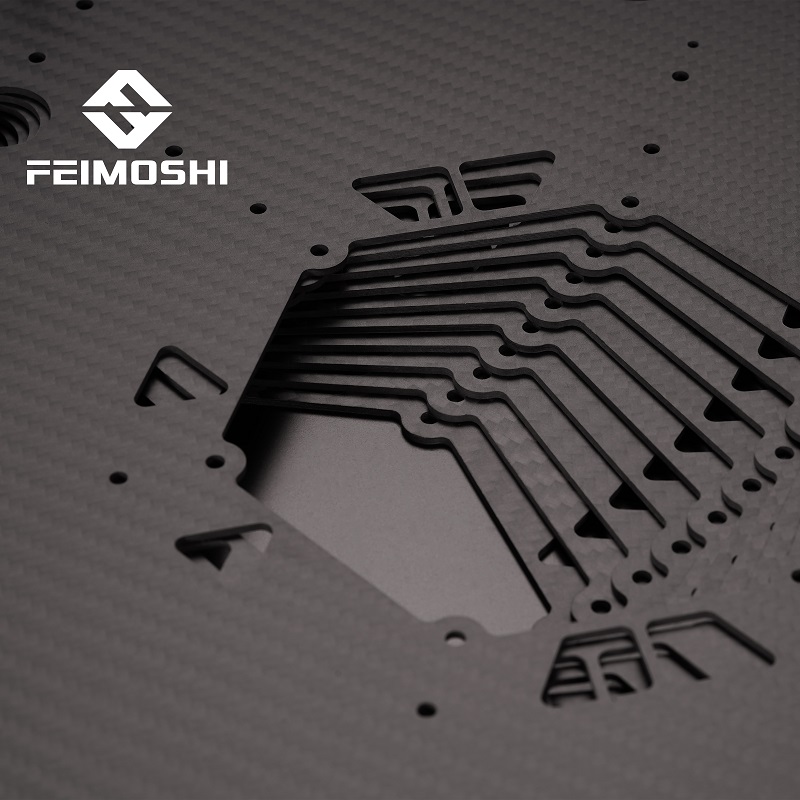

Product detail pictures:

Related Product Guide:

Chopped carbon fiber has high strength, high modulus, low density, high specific performance, no creep, ultra-high temperature resistance in non-oxidizing environment, good fatigue resistance, good electromagnetic shielding, and does not swell or swell in organic solvents, acids and alkalis. Excellent corrosion resistance. High definition Composite Plate Fit - Carbon Fiber-Reinforced full twill matte or glossy 3K carbon fiber plate – Feimoshi , The product will supply to all over the world, such as: Buenos Aires, Morocco, Roman, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

Send your message to us:

Write your message here and send it to us