High Performance Carbon Fiber Laser Cutting - OEM manufacturer custom cnc carbon fiber parts – Feimoshi

High Performance Carbon Fiber Laser Cutting - OEM manufacturer custom cnc carbon fiber parts – Feimoshi Detail:

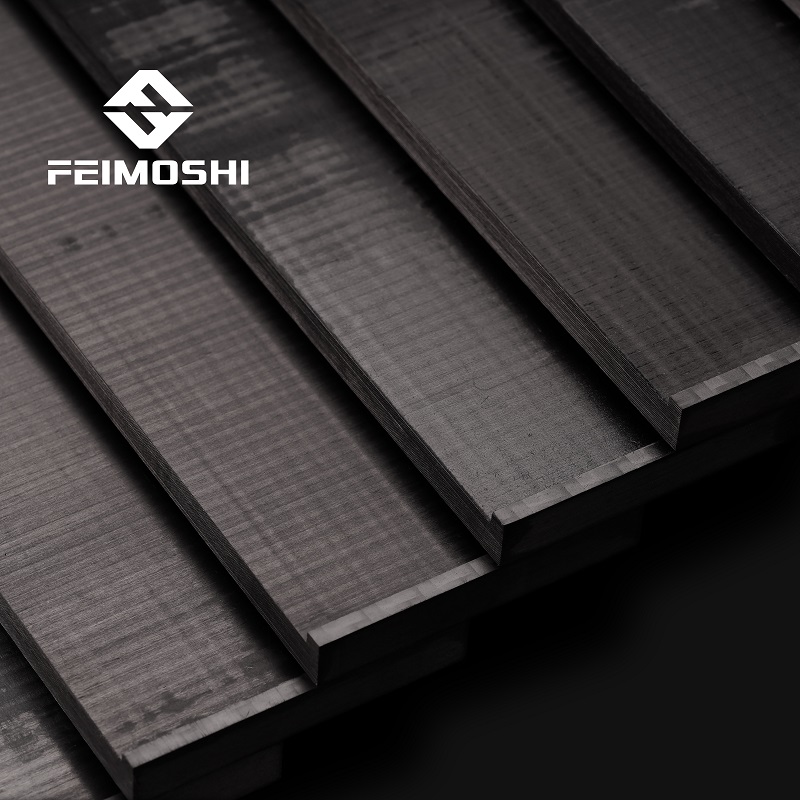

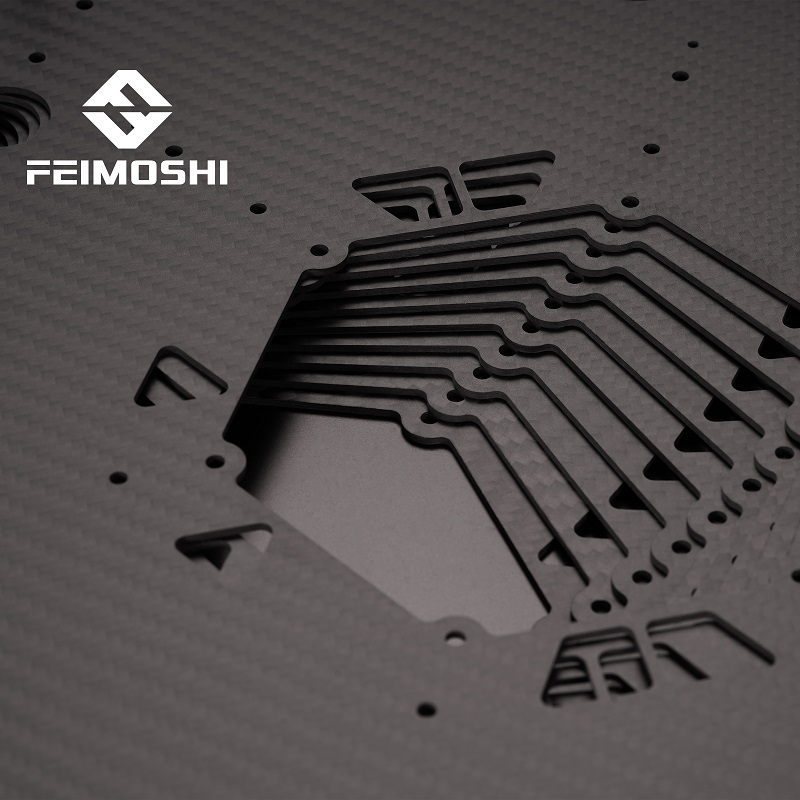

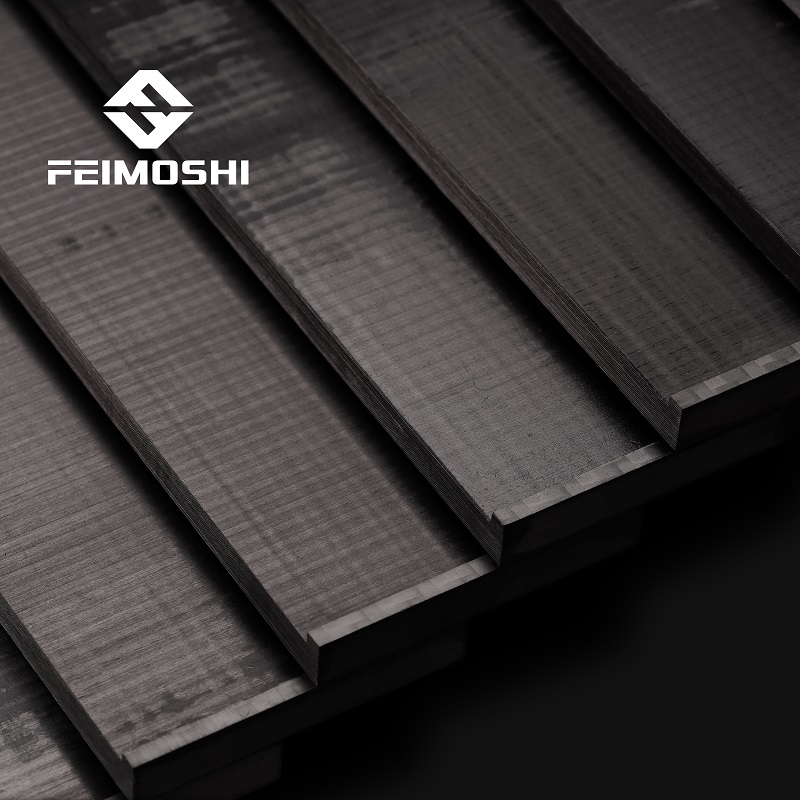

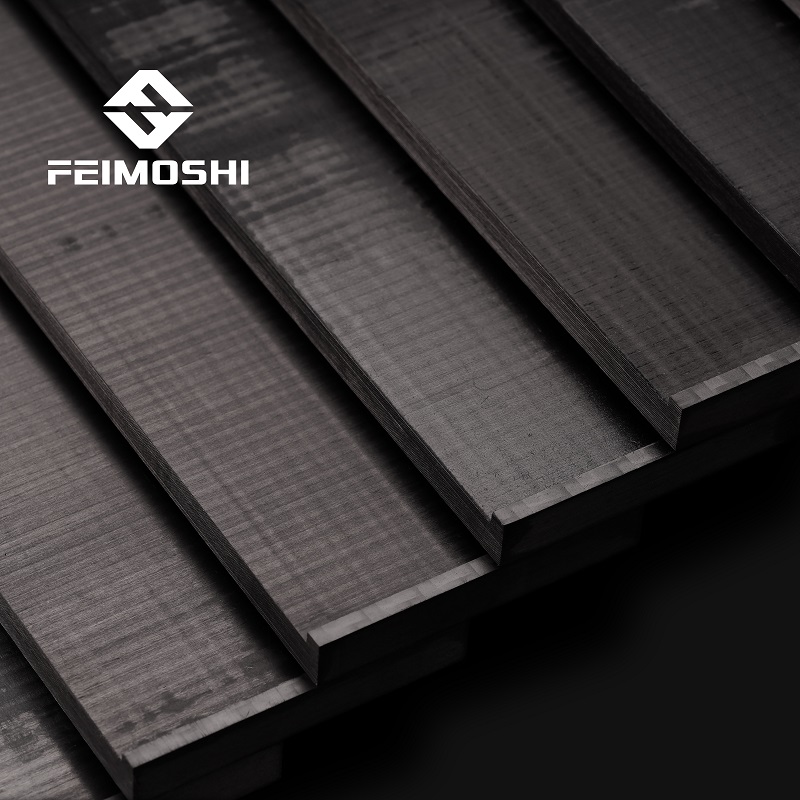

OEM manufacturer custom cnc carbon fiber parts

FMS is one of the top companies in China that specializes in precision machining. We are able to process high precision CNC machining with stable and reliable quality. The current pulse equivalent is generally 0.001mm and high-precision CNC machining system can go up to 0.02-0.05mm. We don’t offer any ready made parts and are manufacturing the custom parts from your drawings or existing samples. We can make the parts with aluminum 6061T, 6063,7075T, brass, plastic,stainless steel, carbon steel, titanium etc.

Payment Type: T/T, Paypal, Western Union

Incoterm: EXW

Min. Order: 10piece

Delivery Time: 10-25 working Days

Transportation: DHL/Fedex/TNT/Epacket

Port: Shenzhen

Product detail pictures:

Related Product Guide:

Carbon fiber is made of man-made fiber with high carbon content and does not melt during the whole process of heat treatment, and is made by thermal stable oxidation treatment, carbonization treatment and graphitization. In today's economic and social development, carbon fiber has long been widely used as a new material, ranging from aerospace industry equipment raw materials to small handbags and other fields. So why is carbon fiber so popular? What are its actual advantages? High Performance Carbon Fiber Laser Cutting - OEM manufacturer custom cnc carbon fiber parts – Feimoshi , The product will supply to all over the world, such as: Hanover, Slovenia, Austria, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

Send your message to us:

Write your message here and send it to us