Low price for Flexible Carbon Fiber Sheet - OEM manufacturer custom cnc carbon fiber parts – Feimoshi

Low price for Flexible Carbon Fiber Sheet - OEM manufacturer custom cnc carbon fiber parts – Feimoshi Detail:

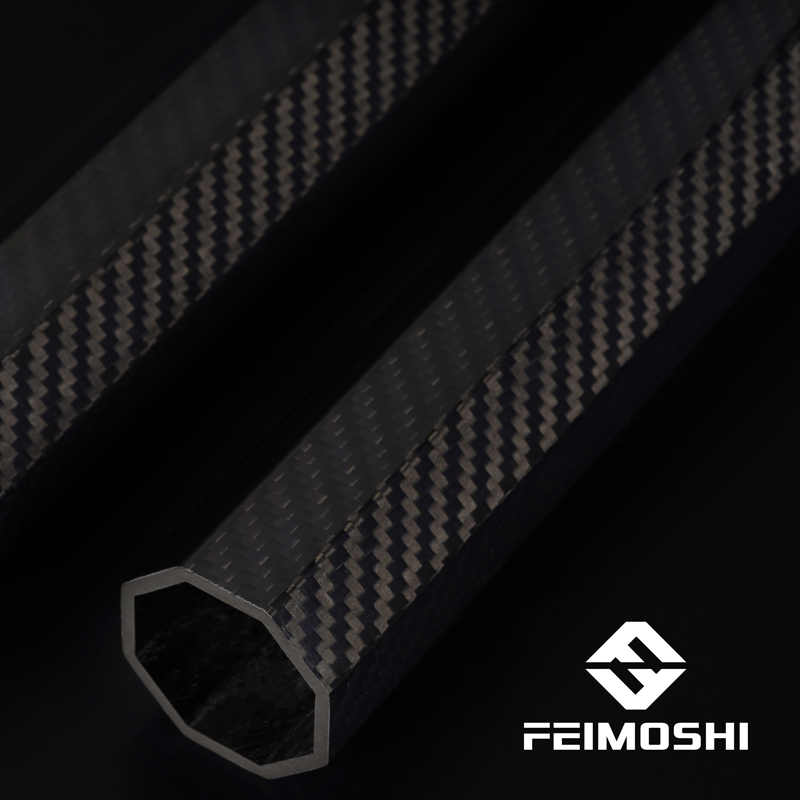

OEM manufacturer custom cnc carbon fiber parts

1. Base

CNC Machined Carbon Fiber Sheet parts is the mainstream environmental friendly new product of the century, it features high strength, abrasion resistant, weather-proof, waterproof, air-pervious.

2. Description

Features:

1. Very light and very strong.

2. Excellent durance.

3. Corrosion resistance.

4. Excellent planeness

5. Very flexible.

6. Nice appearance.

Application:

1. UAV, RC Toy model , Aeromodelling, Helicopter Model.

2. Electrical products.

3. Shipbuilding.

4. Space aviation defense.

5. Sports equipments.

6. Automobile parts.

7. Wind power blades.

8. Spinning Reels Brake Rotor friction plate, Rocker.

9.Medical device(X-ray, DR).

10. Etc.

FAQ

1) Could you do the CNC cutting?

Yes, we could do the CNC cutting for the carbon fiber material.

2) what is the format of the drawings you need?

DXF, DWG and step format are all fine.

3) What is the tolerance of CNC cutting?

About +/-0.2mm

4) What is the largest carbon fiber sheet for cutting?

1000X2500mm cutting is ok for us.

5) How many days for the cutting service?

Normally, it needs about 7-15 working days and it also depends on the order quantity.

Looking for ideal Carbon Fiber FPV Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Hobby Carbon Fiber are quality guaranteed. We are China Origin Factory of Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

At this stage, many product parts are made of carbon fiber. Most parts are not standard plate and tube products. In the application environment, there are some inclination and shape regulations. Carbon fiber composite materials have good ductility, and epoxy resin can complete various intricate shapes in the flow of the mold. At this stage, the customized industry has a very large demand for such special-shaped parts. Some customers do not understand the basic knowledge of the production and application of carbon fiber special-shaped parts. Low price for Flexible Carbon Fiber Sheet - OEM manufacturer custom cnc carbon fiber parts – Feimoshi , The product will supply to all over the world, such as: Belgium, Angola, Russia, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!