OEM/ODM Factory Carbon Fiber Canoe Paddle - custom shaped carbon fiber mounting parts – Feimoshi

OEM/ODM Factory Carbon Fiber Canoe Paddle - custom shaped carbon fiber mounting parts – Feimoshi Detail:

custom shaped carbon fiber mounting parts

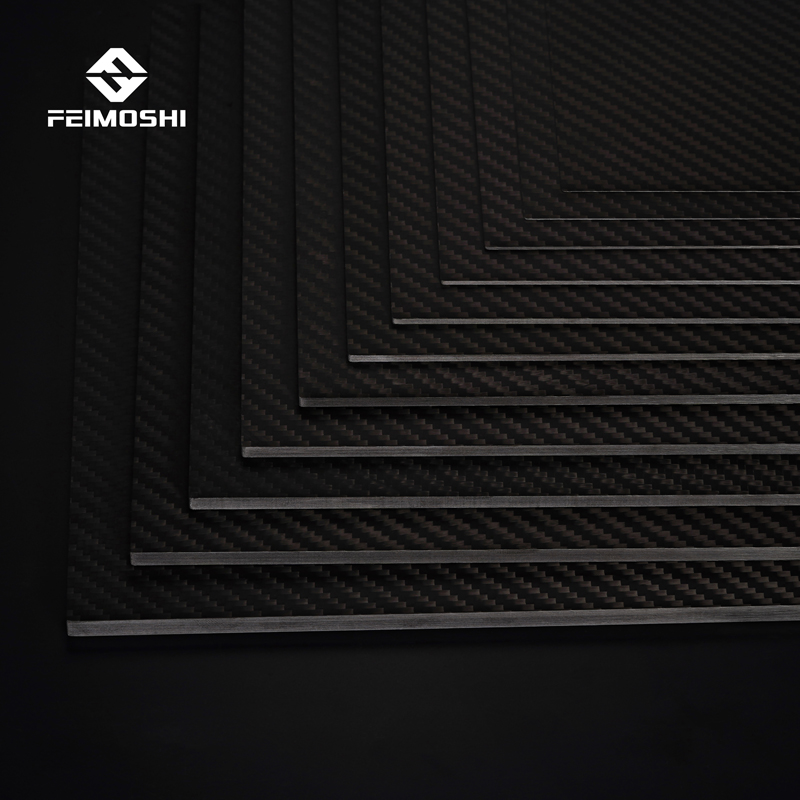

carbon fiber sheet cutting service price 4×8 is widely used in all kinds of metal accessories, leather goods, pens, notebooks, jewelry, furniture and other surface decoration. high-end sports equipment and surface decoration makes it popular.carbon fiber sheet cutting service price 4×8 can be alos used in cell phones, portable computers, aircraft models, car models. Any need of carbon fiber sheet cutting service price 4×8, contact us freely.

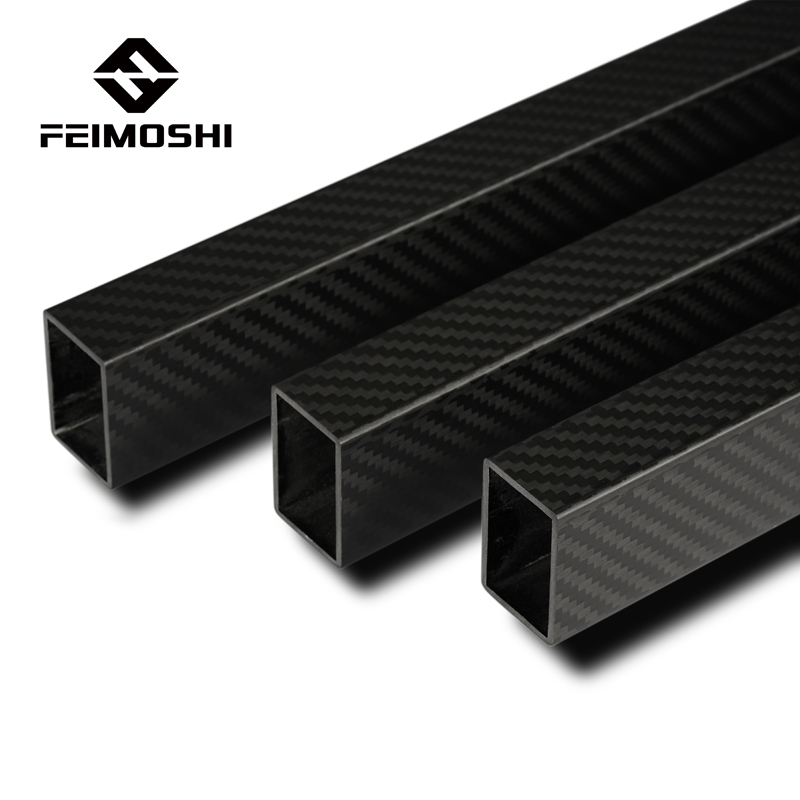

We could do the shaped carbon fiber parts according to your drawings. 3D carbon fiber parts is widely used on carbon fiber frame, carbon fiber drone, UAV, carbon fiber canopy and carbon fiber furniture. Light weight and high strength is the advantage of carbon fiber material. CNC cutting service is special for carbon fiber sheet. We have many thick carbon fiber sheets in stock, such as 400X500mm and 500X600mm. Customized size and thickness are also ok for us. 1000mm width X2500mm length (Different thickness) is avaliable for us.

Normally, shaped carbon fiber parts need a mould to do it. And this shaped type is only for you. We also could do sign the NDA to protect your drawings.

Any interests, please let me know.

Our service

* Drawings, photos and samples are welcome.

* We can produce the products as to your requirement or samples. Special for your own.

* Please contact us freely if there is any question.

* We are looking forward to have a good cooperation with you.

FAQ

1) Do you do the shaped carbon fiber parts?

Yes, Shaped carbon fiber parts is ok for us. And it needs to make a mould to do it.

2) Do we need to make every payment per each order for mould charge?

No, mould charge needs only to pay one time.

3) There is the MOQ requirements?

No, mostly there is no MOQ requirements for mould carbon fiber parts.

4) How many days for the production of shaped carbon fiber parts?

Mould charge: 7-10 working days. Production time: Depending on the order quantity.

5) Payment way?

Paypal/T/T are all ok for us.

Looking for ideal Carbon Fiber Sheet 4×8 Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Cutting Carbon Fiber Sheet are quality guaranteed. We are China Origin Factory of Carbon Fiber Sheet Cutting Service Price. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Chopped carbon fiber has high strength, high modulus, low density, high specific performance, no creep, ultra-high temperature resistance in non-oxidizing environment, good fatigue resistance, good electromagnetic shielding, and does not swell or swell in organic solvents, acids and alkalis. Excellent corrosion resistance. OEM/ODM Factory Carbon Fiber Canoe Paddle - custom shaped carbon fiber mounting parts – Feimoshi , The product will supply to all over the world, such as: Madrid, UK, Dominica, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.