PriceList for Carbon Fiber Profile - customized shaped 100% carbon fiber panel with different dimension – Feimoshi

PriceList for Carbon Fiber Profile - customized shaped 100% carbon fiber panel with different dimension – Feimoshi Detail:

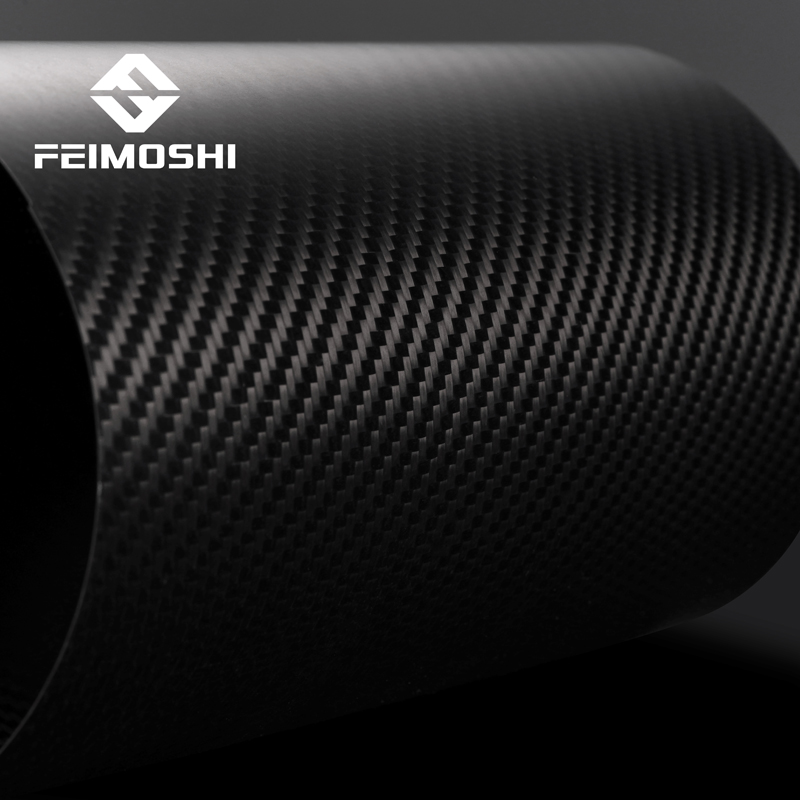

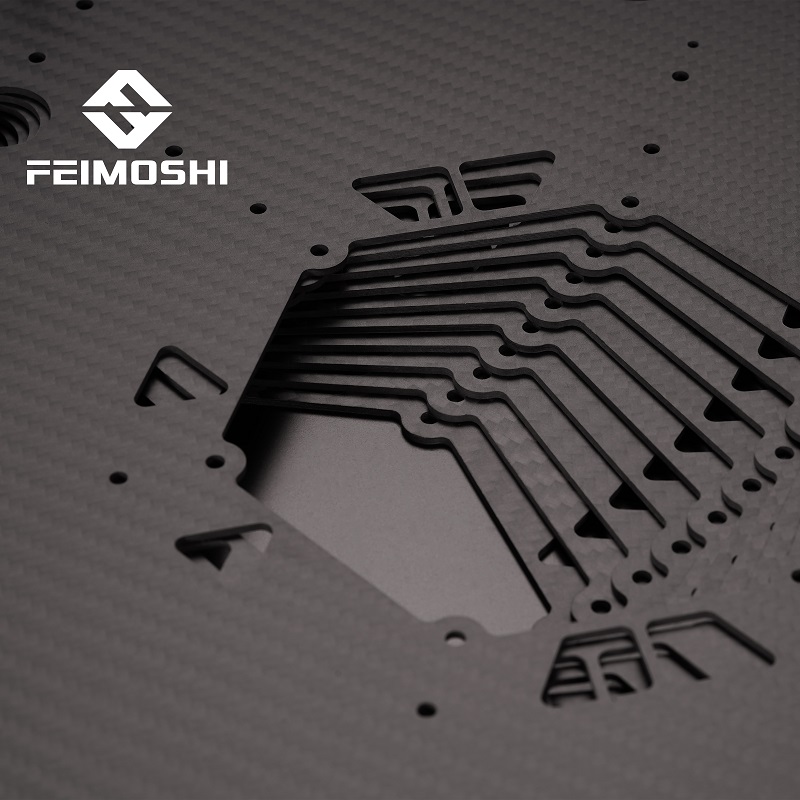

customized shaped 100% carbon fiber panel with different dimension

Below are advantages for CNC machining :

(1) A large amount of reduction in the number of the tooling, and the complex parts of the parts do not require complex tooling. If we want to change the shape and size of the parts, it is only necessary to modify the processing program for the parts, and it is suitable for the development and modification of the new products.

(2) The machining quality is stable, the machining precision is high, and the repetition precision is high, which is suitable for the processing requirements of the aircraft.

(3) The production efficiency is high under the condition of multi variety and small batch production, it can reduce the time of production preparation, machine adjustment and process inspection, and the cutting time is reduced by using the best cutting volume. We also support 4 Axis Cnc Cutting carbon Fiber Tube drilling High-Strength carbon Fiber Pipes use in building construction

FAQ

1) Could you do the CNC cutting?

Yes, we could do the CNC cutting for the carbon fiber material.

2) what is the format of the drawings you need?

DXF, DWG and step format are all fine.

3) What is the tolerance of CNC cutting?

About +/-0.2mm

4) What is the largest carbon fiber sheet for cutting?

1000X2500mm cutting is ok for us.

5) How many days for the cutting service?

Normally, it needs about 7-15 working days and it also depends on the order quantity.

Looking for ideal Carbon Fiber FPV Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Hobby Carbon Fiber are quality guaranteed. We are China Origin Factory of Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Chopped carbon fibers are chopped from PAN-based carbon fiber filaments. PriceList for Carbon Fiber Profile - customized shaped 100% carbon fiber panel with different dimension – Feimoshi , The product will supply to all over the world, such as: Lesotho, Philippines, Morocco, Disadvantages of carbon fiber frames: (1) Complicated internal stress calculation; carbon fiber frame is composed of carbon fiber, which is characterized by strong tensile strength, but weak breaking compressive strength. Rigidity), the carbon fiber sheet is re-formed according to the calculation. The production and processing technology varies from manufacturer to manufacturer. It is important to select products from reliable manufacturers with work experience.(2). It is difficult to change the specifications; it is difficult to change the specifications because the molds are formed after forming. There is no way to correspond to order information of multiple specifications and styles.(3). Aging; will the application of epoxy resin cause aging? This is a study of the subject of beings, and it will slowly turn white when placed under the sun. Naturally this situation is related to the technicality of the manufacturer. Try not to place it in the sun.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.