Professional China Carbon Fiber Boom - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi

Professional China Carbon Fiber Boom - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi Detail:

Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max

The ultra-thin autoclave kevlar phone case is on sale. Its main features are thinness, toughness, high-quality appearance, and comfortable touch.

Material: autoclave kevlar

Thickness: 0.35mm ultra thin

Finish: autoclave process

MOQ: 10pcs

Color: black, red, blue

Shipping methods: Express services like DHL, UPS, FedEx, TNT, or Air shipping, Sea shipping

Why choose Autoclave phone case?

Easy to use even with complex curvature of the product

Zero voids.

Perfect appearance of the carbon fiber fabric.

Excellent fatigue resistance.

Laminate thickness keeped under control.

The process is clean.

The process offers better quality as well as conformity.

Why choose Aramid/Kevlar fibers?

High strength

Good resistance to abrasion

Good resistance to organic solvents

Non-conductive

No melting point

Low flammability

Good fabric integrity at elevated temperatures

Note: We support free sample service!

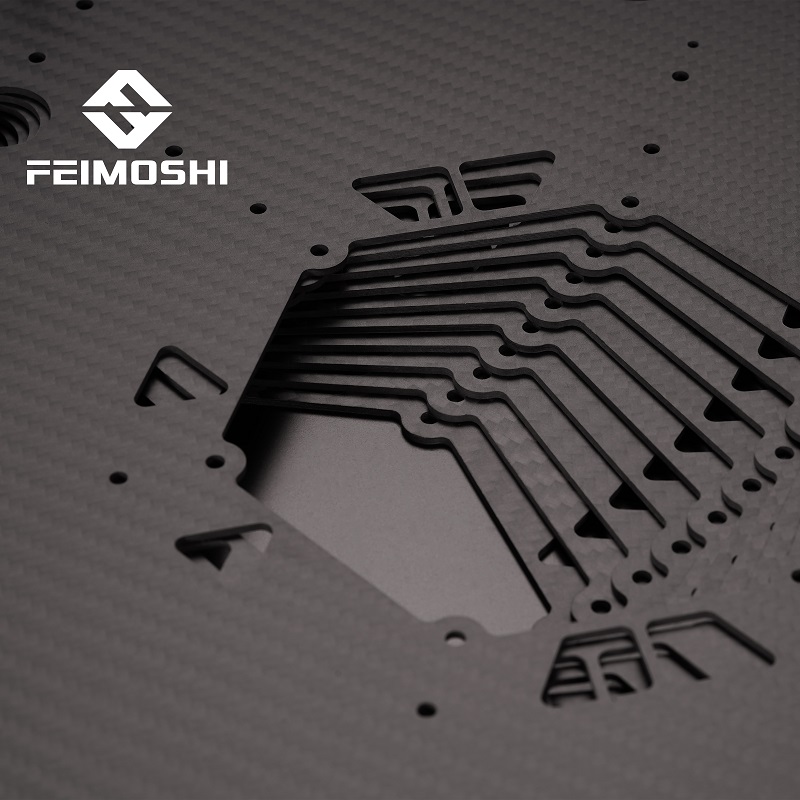

Product detail pictures:

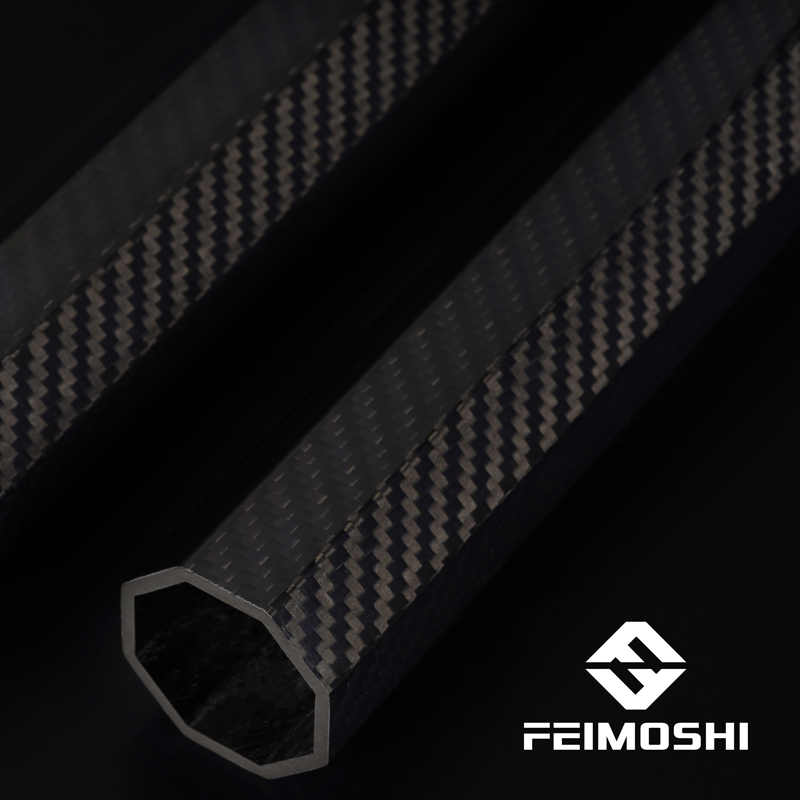

Related Product Guide:

In the aerospace industry, carbon fiber sheets are used to make aircraft components such as fuselage panels, control surfaces and wingtips. The resulting components are lightweight, yet robust. Carbon fiber is widely adopted by the aerospace industry due to its superior strength-to-weight ratio. Because carbon fiber has such a beautiful appearance, it is also ideal for aircraft interiors. Professional China Carbon Fiber Boom - Light weight autoclave kevlar phone shell iPhone13 mini, 13, 13 Pro, 13 Pro Max – Feimoshi , The product will supply to all over the world, such as: Philadelphia, Argentina, Bangalore, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!