Professional China Composite Plate - 1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet – Feimoshi

Professional China Composite Plate - 1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet – Feimoshi Detail:

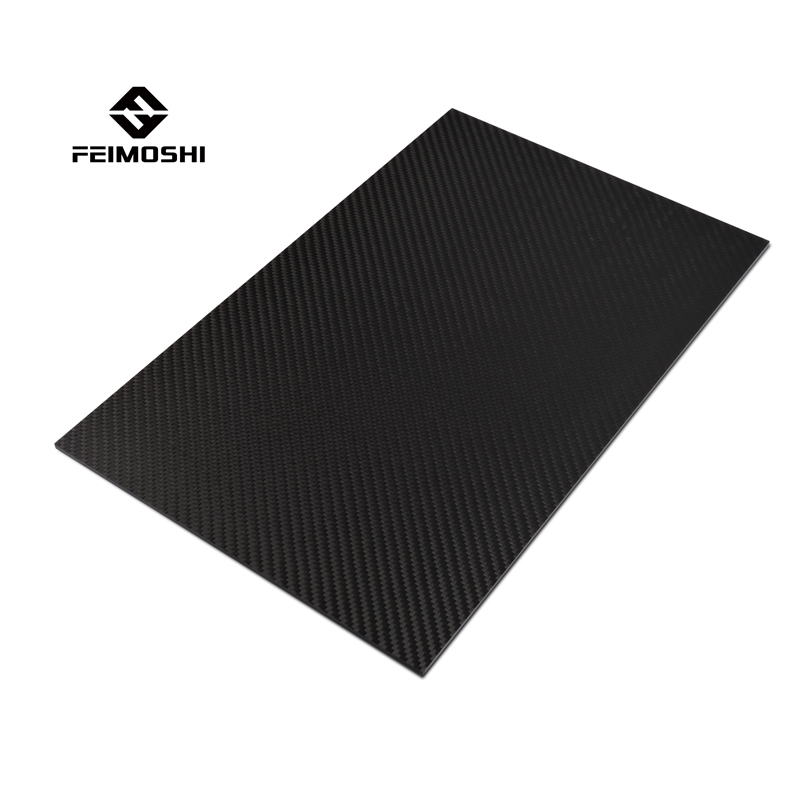

1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet

1K means 1 carbon yarn contains 1000 filaments, 2K means 2000 filaments, and so on. We have 1K/3K/6K/12K carbon fiber fabric. The smaller K is, more complicated the production process is! so the small K carbon fiber fabric is more expensive.

Carbon Fiber Cloth is made of carbon fiber by woven unidirectional, plain weaving or twill weaving style. The carbon fibers we use contain high strength-to-weight and stiffness-to-weight ratios, carbon fabrics are thermally and electrically conductive and exhibit excellent fatigue resistance. When properly engineered, carbon fabric composites can achieve the strength and stiffness of metals at significant weight savings. Carbon fabrics are compatible with various resin systems including epoxy, polyester and vinyl ester resins.

There are unidirectional carbon fiber fabric used as reinforcement clothing for bridge, road and building. The bidirectional cabon fiber fabric are woven with Plain ,Twill style,satin weave and other pattern.

we have 100gsm/120gsm/140gsm/200gsm/240gsm/280gsm/320gsm/400gsm/480gsm/640gsm for choosing.

Looking for ideal 3k Carbon Fiber Sheet 2.5mm Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Zoltek Carbon Fiber Data Sheet are quality guaranteed. We are China Origin Factory of Carbon Fiber Topsheet Snowboard. If you have any question, please feel free to contact us.

Product Categories : Carbon Fiber Sheet > Full Carbon Fiber Sheet

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Professional China Composite Plate - 1K 3K twill carbon fiber plate 20mm thick carbon fiber sheet – Feimoshi , The product will supply to all over the world, such as: Netherlands, Ghana, Macedonia, Disadvantages of carbon fiber frames: (1) Complicated internal stress calculation; carbon fiber frame is composed of carbon fiber, which is characterized by strong tensile strength, but weak breaking compressive strength. Rigidity), the carbon fiber sheet is re-formed according to the calculation. The production and processing technology varies from manufacturer to manufacturer. It is important to select products from reliable manufacturers with work experience.(2). It is difficult to change the specifications; it is difficult to change the specifications because the molds are formed after forming. There is no way to correspond to order information of multiple specifications and styles.(3). Aging; will the application of epoxy resin cause aging? This is a study of the subject of beings, and it will slowly turn white when placed under the sun. Naturally this situation is related to the technicality of the manufacturer. Try not to place it in the sun.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.