Rapid Delivery for Carbon Fiber Insoles - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi

Rapid Delivery for Carbon Fiber Insoles - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi Detail:

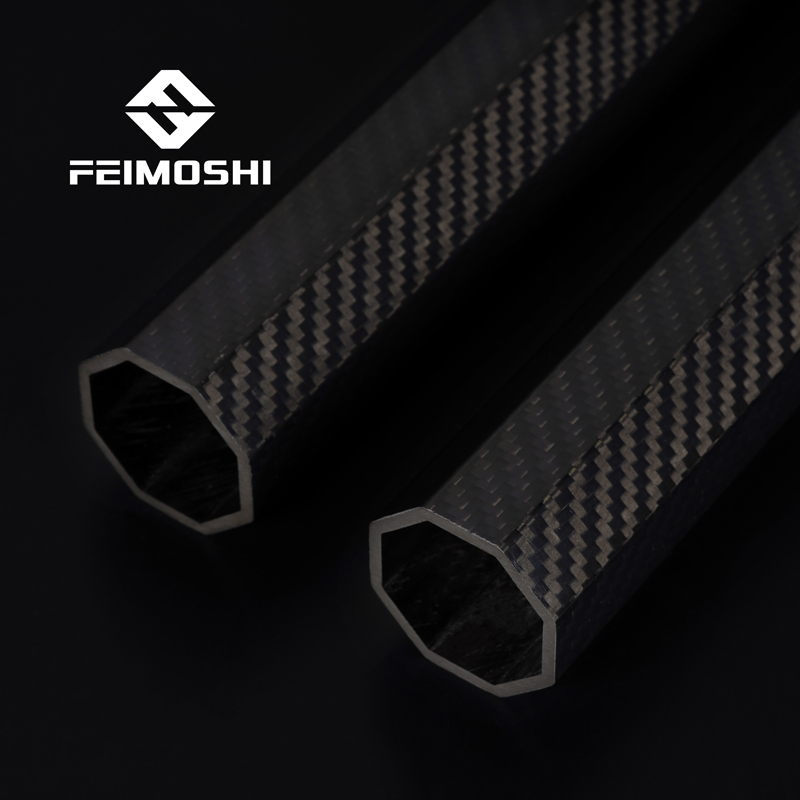

DIY 3K large diameter Carbon fiber round/square rod boom

Product Description

Our Carbon Fiber Tube is great performance and appearance. Made from attractive pattern plain twill or as customer requirement.

We make the Carbon Fiber Tubes by rolling-Wrapped process. It makes the carbon fiber tube much stronger and professional. More and more customers choose the full carbon fiber tube to make the drone arm, desk leg, gimbal stand and so on. And you could offer your creative ideal, we could help you to come ture. Carbon fiber tube is also widly used in building construction. It makes them much lighter and easy to move.

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness:1.0mm/1.5mm/2.0mm

Length: longest length is 2000mm

Appearance: 3K twill weave, plain weave, or other

Looking for ideal Carbon Fiber carbon fiber tube Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Epoxy Resin Carbon Fiber 3k Woven are quality guaranteed. We are China Origin Factory of Carbon Fiber Shape. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber tube is one of the more common application forms of carbon fiber composite materials in industrial, civil, medical and other fields. Due to its advantages of light weight, high strength and flexible design, it has the development trend of becoming a new generation of parts and components. Rapid Delivery for Carbon Fiber Insoles - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi , The product will supply to all over the world, such as: Melbourne, Houston, Seattle, Carbon fiber tube, also known as carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated and cured by pultrusion (twisting).Carbon fiber tubes have the advantages of high strength, long life, corrosion resistance, light weight and low density, and are widely used in kites, aircraft models, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, small thermal expansion coefficient, self-lubrication, energy absorption and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance and so on. The advantage is that it has very good tensile strength (for example, calculated in units of 12,000 filaments, its tensile strength is kg/mm2—400).

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.