Wholesale Price Composite Parts - custom shaped carbon fiber mounting parts – Feimoshi

Wholesale Price Composite Parts - custom shaped carbon fiber mounting parts – Feimoshi Detail:

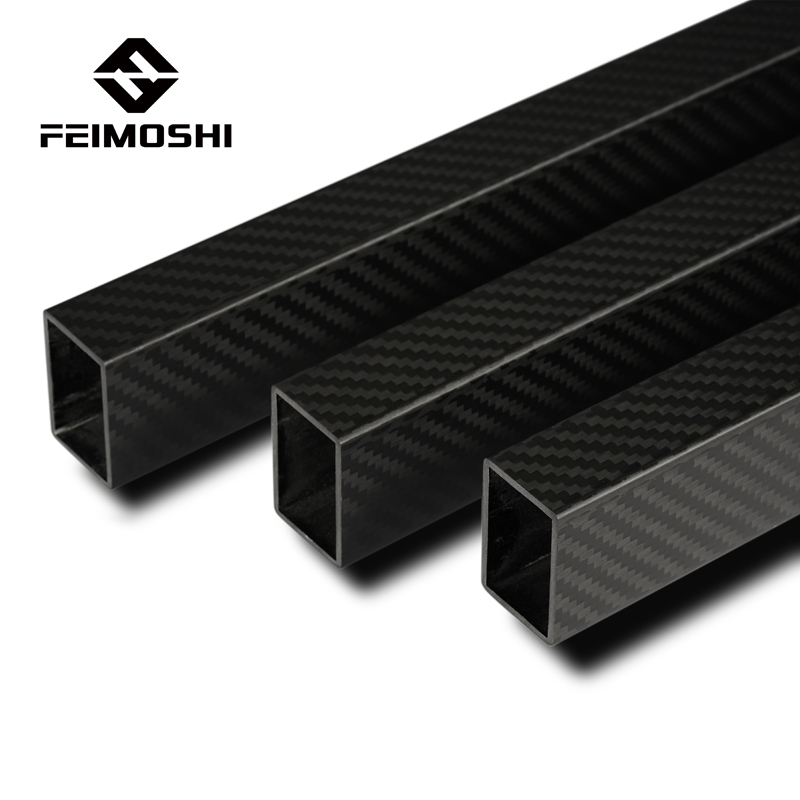

custom shaped carbon fiber mounting parts

carbon fiber sheet cutting service price 4×8 is widely used in all kinds of metal accessories, leather goods, pens, notebooks, jewelry, furniture and other surface decoration. high-end sports equipment and surface decoration makes it popular.carbon fiber sheet cutting service price 4×8 can be alos used in cell phones, portable computers, aircraft models, car models. Any need of carbon fiber sheet cutting service price 4×8, contact us freely.

We could do the shaped carbon fiber parts according to your drawings. 3D carbon fiber parts is widely used on carbon fiber frame, carbon fiber drone, UAV, carbon fiber canopy and carbon fiber furniture. Light weight and high strength is the advantage of carbon fiber material. CNC cutting service is special for carbon fiber sheet. We have many thick carbon fiber sheets in stock, such as 400X500mm and 500X600mm. Customized size and thickness are also ok for us. 1000mm width X2500mm length (Different thickness) is avaliable for us.

Normally, shaped carbon fiber parts need a mould to do it. And this shaped type is only for you. We also could do sign the NDA to protect your drawings.

Any interests, please let me know.

Our service

* Drawings, photos and samples are welcome.

* We can produce the products as to your requirement or samples. Special for your own.

* Please contact us freely if there is any question.

* We are looking forward to have a good cooperation with you.

FAQ

1) Do you do the shaped carbon fiber parts?

Yes, Shaped carbon fiber parts is ok for us. And it needs to make a mould to do it.

2) Do we need to make every payment per each order for mould charge?

No, mould charge needs only to pay one time.

3) There is the MOQ requirements?

No, mostly there is no MOQ requirements for mould carbon fiber parts.

4) How many days for the production of shaped carbon fiber parts?

Mould charge: 7-10 working days. Production time: Depending on the order quantity.

5) Payment way?

Paypal/T/T are all ok for us.

Looking for ideal Carbon Fiber Sheet 4×8 Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Cutting Carbon Fiber Sheet are quality guaranteed. We are China Origin Factory of Carbon Fiber Sheet Cutting Service Price. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

At present, the carbon fiber industry is in a period of explosive growth, and the growth rate of the carbon fiber demand market will remain at around 17% in the future. Wholesale Price Composite Parts - custom shaped carbon fiber mounting parts – Feimoshi , The product will supply to all over the world, such as: Ukraine, Naples, Macedonia, Carbon fiber board mainly has the following characteristics:1. Light weight and high toughness. The weight of carbon fiber board is similar to that of plastic of the same volume, which is 20% of that of steel. Although it is light, its toughness is comparable to that of steel. It can be bent and coiled.2. High tensile coefficient. The tensile coefficient of carbon fiber is several times higher than that of steel, and it has good resistance to deformation, so carbon fiber boards are used in concrete reinforcement, bridge reinforcement and other places.3. Good chemical stability. Carbon fiber board base material is carbon element, carbon element has good chemical stability, and has the characteristics of corrosion resistance, acid and alkali resistance, wear resistance and so on.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!