18 Years Factory Carbon Fiber Sup Paddle - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi

18 Years Factory Carbon Fiber Sup Paddle - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi Detail:

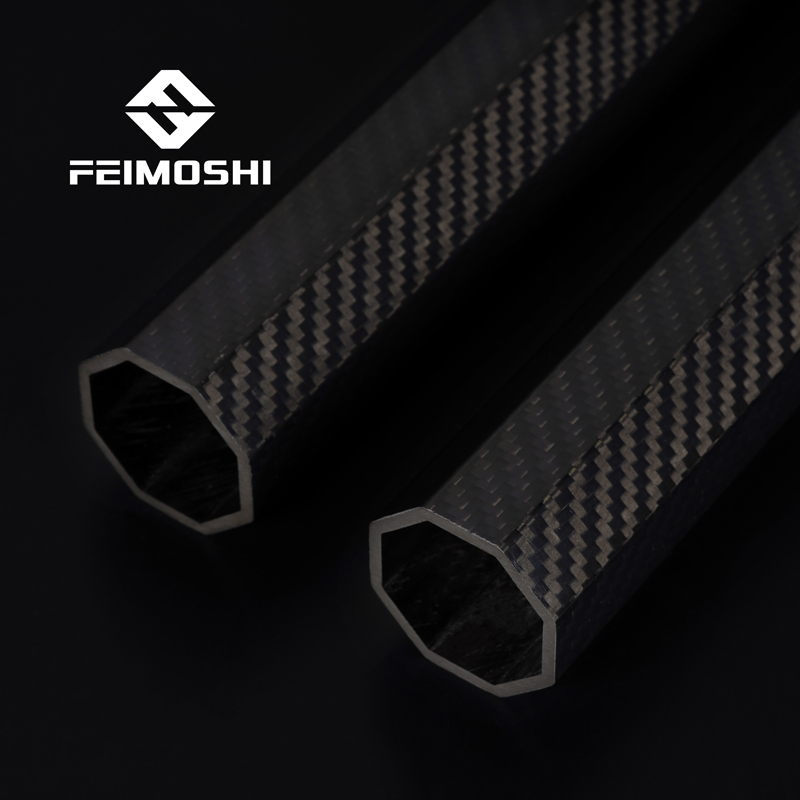

DIY 3K large diameter Carbon fiber round/square rod boom

Product Description

Our Carbon Fiber Tube is great performance and appearance. Made from attractive pattern plain twill or as customer requirement.

We make the Carbon Fiber Tubes by rolling-Wrapped process. It makes the carbon fiber tube much stronger and professional. More and more customers choose the full carbon fiber tube to make the drone arm, desk leg, gimbal stand and so on. And you could offer your creative ideal, we could help you to come ture. Carbon fiber tube is also widly used in building construction. It makes them much lighter and easy to move.

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness:1.0mm/1.5mm/2.0mm

Length: longest length is 2000mm

Appearance: 3K twill weave, plain weave, or other

Looking for ideal Carbon Fiber carbon fiber tube Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Epoxy Resin Carbon Fiber 3k Woven are quality guaranteed. We are China Origin Factory of Carbon Fiber Shape. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. 18 Years Factory Carbon Fiber Sup Paddle - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi , The product will supply to all over the world, such as: Chicago, Jamaica, French, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.