2021 China New Design Composite Mount - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi

2021 China New Design Composite Mount - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi Detail:

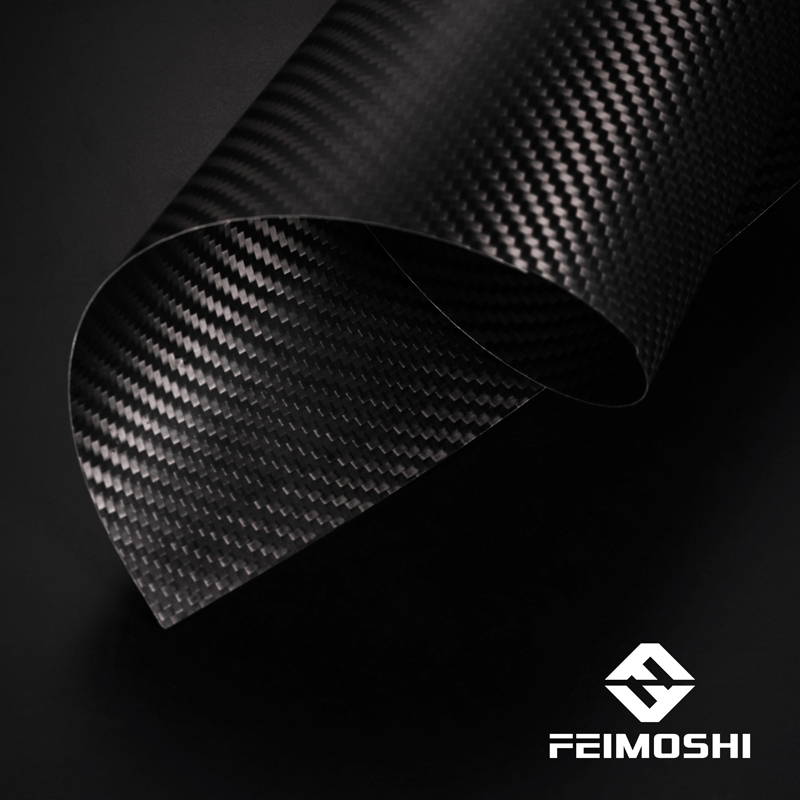

2.0mm Twill matte CNC carbon fiber composite cutting opener mount

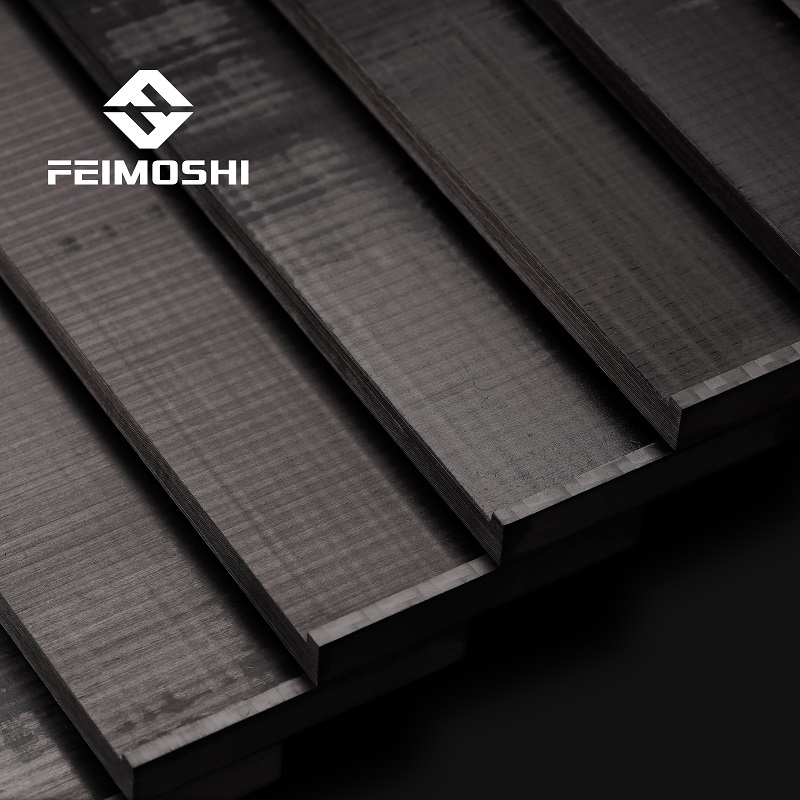

400X500X2.0mm and 500X600X2.0mm 3K twill matte carbon fiber plate could be cut to different types. 2.0mm thickness is very suitable for the carbon fiber opener. Normally, we could do some stocked quantity for 2.0mm thickness. Carbon fiber sheet is made of 3K twill matte cloth and UD cloth and epoxy resin.

CNC cutting service is ok for us. If you feel that the edge is very sharp, we could do the chamfer for the edge to make it more professional. Also wanting to connect the hardware with carbon fiber parts, contact us freely. Our engineer team will offer some good suggestions for your choosing.

Product detail pictures:

Related Product Guide:

When it comes to carbon fiber, you should know something! Known as the "king of new materials" and "black gold", the new material has the advantages of light weight, high strength, high temperature resistance and corrosion resistance. With the development of life, it has been applied in more and more fields.So what carbon fiber products will we be familiar with but unfamiliar with in our daily life?1. In the automobile industry, carbon fiber also plays an important role. Nowadays, automobiles pay more and more attention to energy saving and emission reduction, and the realization of energy saving and emission reduction is mainly due to the lightweight structure. Therefore, some auto parts are now made of carbon fiber materials. Thereby achieving the effect of weight loss.2. In sports goods, such as bicycles, scooters, racing cars and other sports goods can be made of carbon fiber materials.3. On jewelry, carbon fiber can be used to make wallets and glasses.4.On tools, carbon fiber ruler, carbon fiber saber, etc. 2021 China New Design Composite Mount - 2.0mm Twill matte CNC carbon fiber composite cutting opener mount – Feimoshi , The product will supply to all over the world, such as: Mecca, Eindhoven, Macedonia, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

Send your message to us:

Write your message here and send it to us