2021 Good Quality Cut Cnc - CNC cutting Carbon fiber Structural Shapes plate – Feimoshi

2021 Good Quality Cut Cnc - CNC cutting Carbon fiber Structural Shapes plate – Feimoshi Detail:

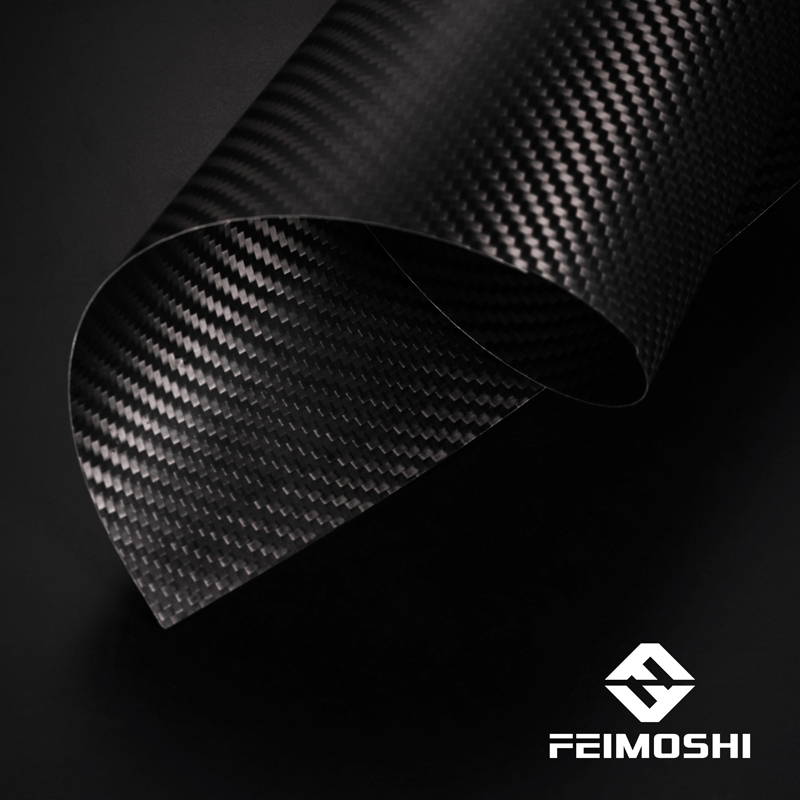

CNC cutting Carbon fiber Structural Shapes plate

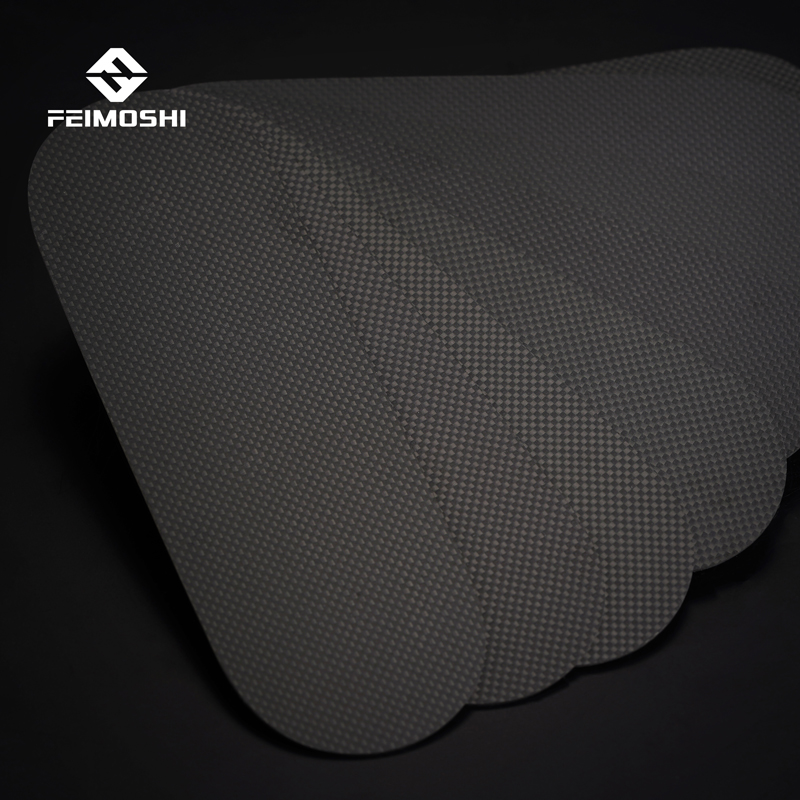

CNC cutting carbon fiber accessories could be widely used in FPV drone, Medical, Industury, building construction. We have many branded customers to make their products more professional and get a good feedback for the carbon fiber material. We could do the thick carbon fiber sheet, like 0.3mm, 1.0mm, 2.0mm….6.0mm, 10.0mm, 20.0mm and so on. We have professional workers to do the thick carbon fiber sheet cutting. And it solves many problems when using in construction, furniture, ect.

Carbon fiber chamfer, carbon fiber countersunk and carbon fiber drilling are also ok for us.

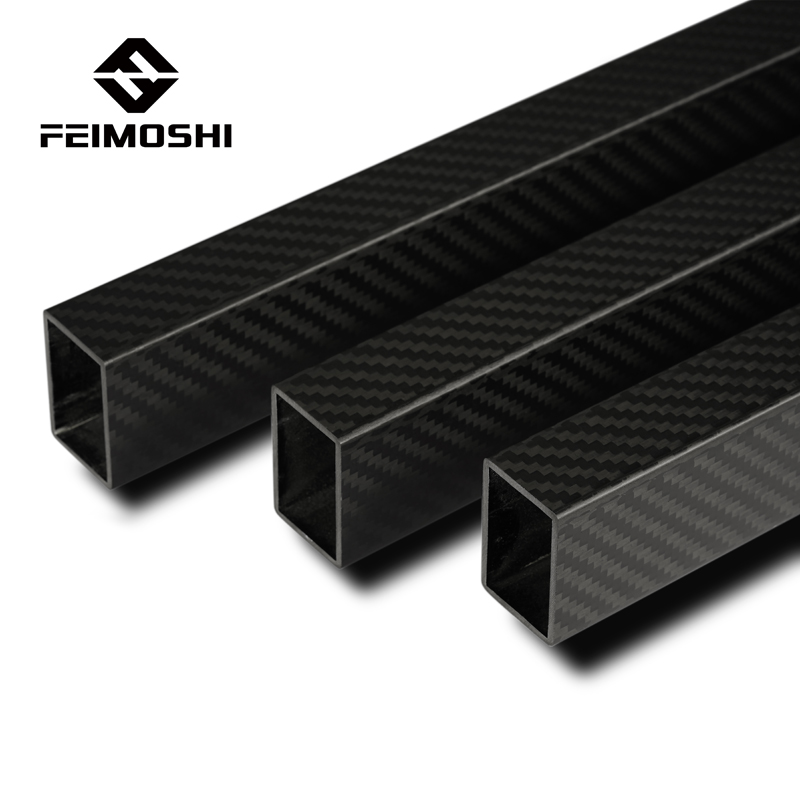

Meantime, we have various size carbon fiber tube, shaped carbon fiber parts service and offer the OEM/ODM service for you.

FAQ

Q1. How many years in this industry?

A: We specialized in this line for many years and got lots of satisfied feedback from branding businesses.

Q2: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q3: What is the lead time?

A: Sample needs 1-3 days, mass production needs 10-15 days, also according to the order volume.

Q4: Do you have any MOQ limit?

A: No MOQ for instock parts and 2000pcs for non-stock products.

Q5: Can you accept mixed batch of different products?

A: Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc

Q6: How do you ship the goods and how long does it take arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

Looking for ideal OEM Service Manuals Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Service First OEM are quality guaranteed. We are China Origin Factory of Amazon OEM Service. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The basic properties of chopped carbon fiber are mainly inherited from its raw material, continuous carbon fiber. What kind of continuous carbon fiber is used as the raw material also directly determines the price of chopped carbon fiber. The tensile strength of continuous carbon fibers directly affects the tensile properties of chopped carbon fiber composite thermoplastics. Some chopped carbon fiber manufacturers will mix different types of continuous carbon fibers due to insufficient raw material supply or cost issues, but this will lead to unstable properties of chopped carbon fiber composite thermoplastic materials. Therefore, when purchasing chopped carbon fiber, it is best to ask the supplier to indicate the type or main performance of continuous carbon fiber on the quality inspection sheet. 2021 Good Quality Cut Cnc - CNC cutting Carbon fiber Structural Shapes plate – Feimoshi , The product will supply to all over the world, such as: Florida, Jersey, Lyon, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.