Wholesale Rc Composite Frame - 3K Laser cutting full carbon fiber sheet using in structural – Feimoshi

Wholesale Rc Composite Frame - 3K Laser cutting full carbon fiber sheet using in structural – Feimoshi Detail:

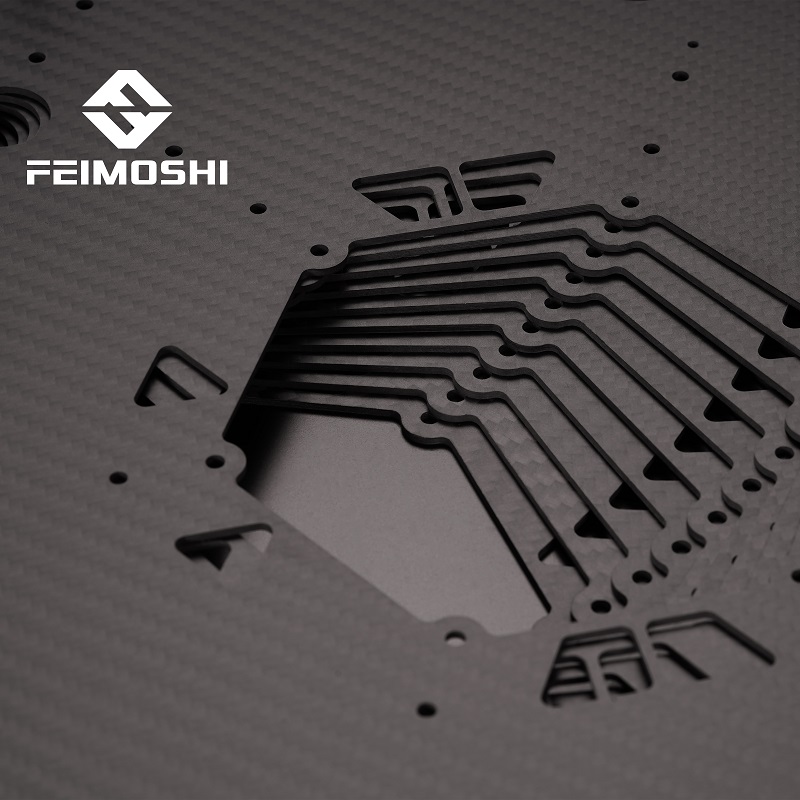

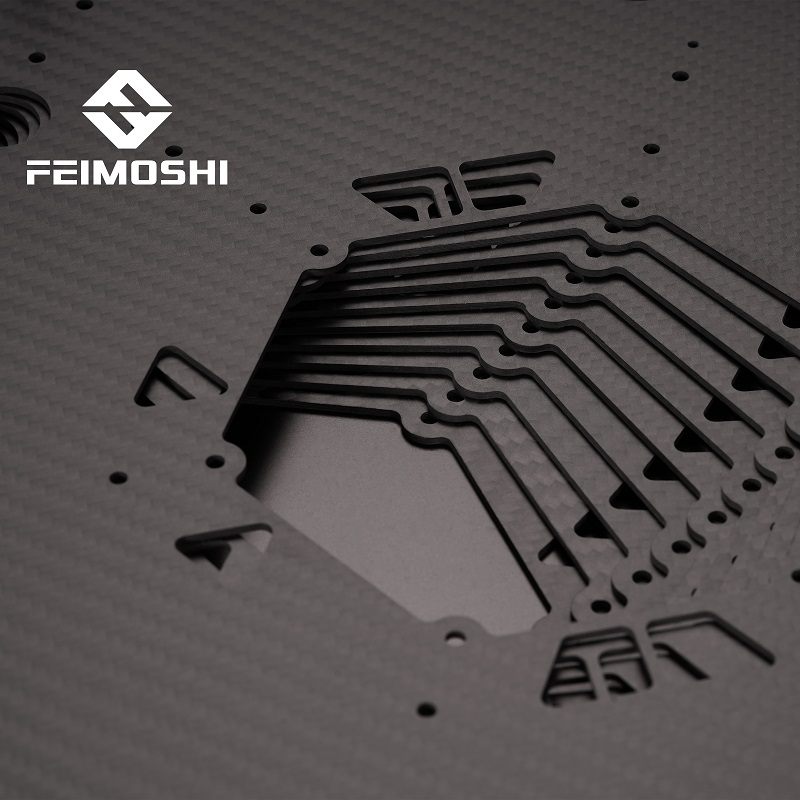

3K Laser cutting full carbon fiber sheet using in structural

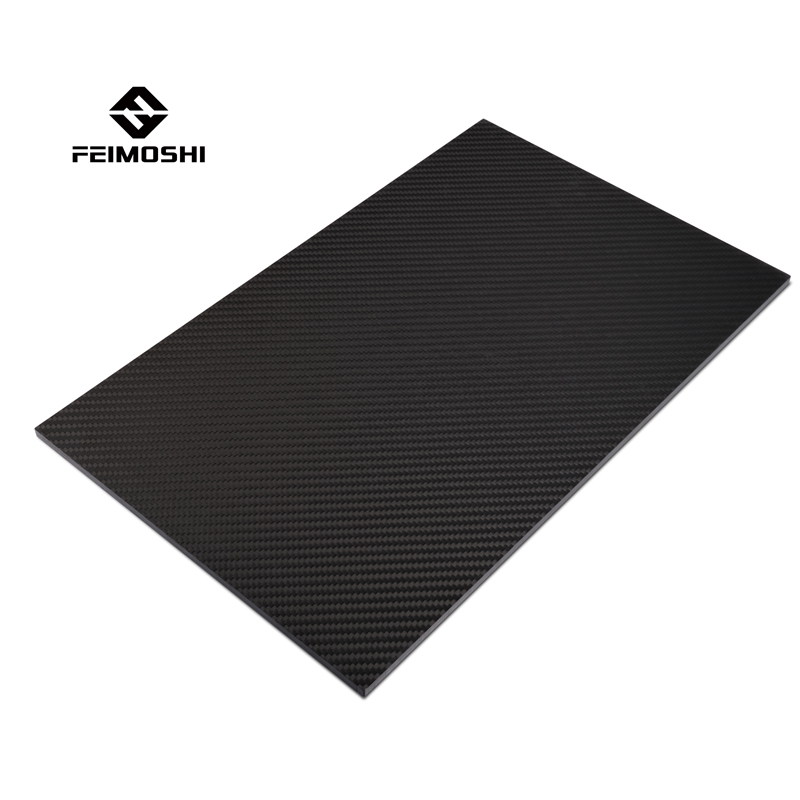

About the 3k twill matte Carbon Fiber Sheet,it is stronger and lighter.

Normally we have the thickness from 0.3mm to 30.0mm,especially we are strong in the field of CNC Carbon Fiber Cutting Service.

Our normal stock including full carbon fiber sheet(400X500mm, 500X600mm), carbon fiber round tube(Various OD and ID), carbon fiber octagon tube(20X30mm, 30X30mm), carbon fiber square tube(10X10mm, 18X18mm, 20X20mm, 25X25mm, 30X30mm), carbon fiber curved tube(22mm and 25mm).

CNC carbon fiber customized cutting is possible to process complex surfaces that are difficult to be machined by conventional methods, and can even process some unobservable parts.

FAQ

1) Could we order one set frame?

Yes, normally, we make the quotation according to the whole plate(400X500mm or 500X600mm). It will be more competieve price based on the quantity in whole plate.

2)Do you do the carbon fiber chamfer and carbon fiber countersunk?

Yes, we have many years experience for the chamfer and countersunk.(DXF, DWG, Step format)

3)Could you do the forged plate?

Yes, forged plate is the new material. We would like to try to offer the perfect plates.

4)Do you help us to check the drawing’s hole size?

Yes, our engineer will check the drawings when cutting.

5)How many days for the cutting and plate?

Normally, it needs about 7-15 working days to complete it. Also we have to promise the quality 100%.

Looking for ideal 3.0mm Carbon Fiber Sheet Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 4.5mm Carbon Fiber Sheet are quality guaranteed. We are China Origin Factory of 5.0mm Carbon Fiber Sheet. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Composite materials composed of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Because every kilogram of the weight of the space vehicle is reduced, the launch vehicle can be reduced by 500 kilograms. Therefore, there is a race to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, and the carbon fiber composite material used in it has accounted for 1/4 of the weight of the whole aircraft and 1/3 of the weight of the wing. According to reports, the key components of the three rocket thrusters on the US space shuttle and the advanced MX missile launch tube are all made of advanced carbon fiber composite materials. Wholesale Rc Composite Frame - 3K Laser cutting full carbon fiber sheet using in structural – Feimoshi , The product will supply to all over the world, such as: Johannesburg, Qatar, Italy, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.