2021 High quality Carbon Fiber Panel Sheet - Plain weave glossy or matte carbon fiber sheet – Feimoshi

2021 High quality Carbon Fiber Panel Sheet - Plain weave glossy or matte carbon fiber sheet – Feimoshi Detail:

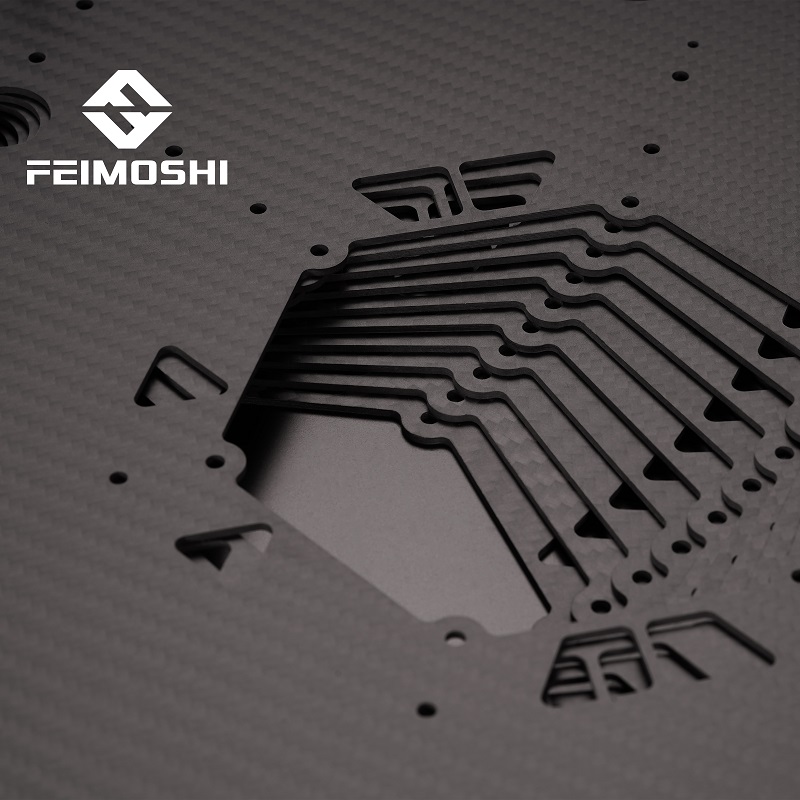

Plain weave glossy or matte Carbon Fiber Sheets

1) cnc turned parts Material: Full Carbon Fiber Plate

2) We manufacture metal parts according to customers’ designs;

3) We can offer material certification, test report and related surface-treatment report;

4) cnc turned parts Process: Cnc Cutting Service, Milling, drilling, Turning;

5) Products shown on the website are OEM ;

6) The products shown here only to present the scope of our manufacturing activities, not for sale;

7) Customized designs are welcome ;

8) cnc auto parts OEM/ODM orders are welcome;

9) More information about full carbon Fiber Plates and CNC Carbon Fiber Cutting, please contact us.

Looking for ideal Carbon Fiber Steering Wheel Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the A Carbon Fiber Bike are quality guaranteed. We are China Origin Factory of Carbon Fiber Case. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Chopped carbon fibers are chopped from PAN-based carbon fiber filaments. 2021 High quality Carbon Fiber Panel Sheet - Plain weave glossy or matte carbon fiber sheet – Feimoshi , The product will supply to all over the world, such as: Bangladesh, Czech, New Zealand, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!