2021 Latest Design Carbon Fiber Uses In Construction - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi

2021 Latest Design Carbon Fiber Uses In Construction - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi Detail:

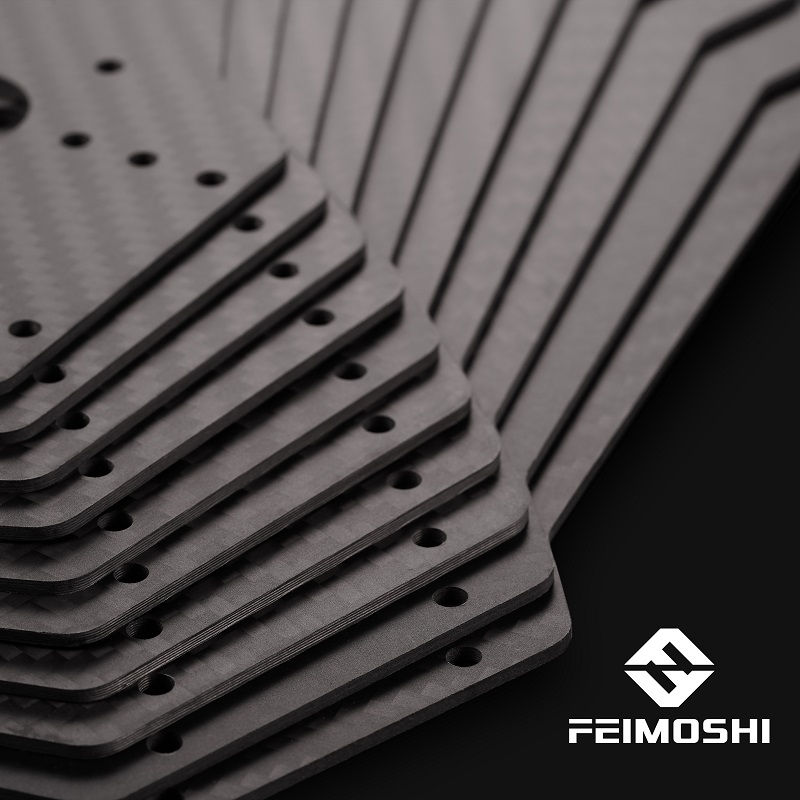

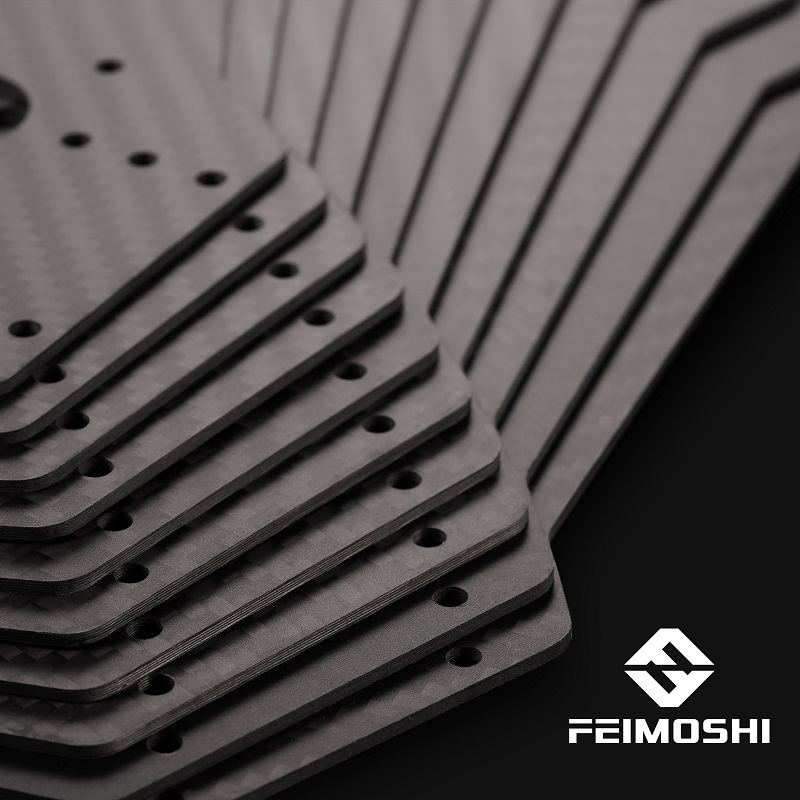

3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels

We have advanced production equipment, which can process carbon fiber plates of various specifications and sizes to meet the needs of different customers.

Hobbycarbon carbon fiber sheets are made from carbon fiber fabric and epoxy resins, Any required size carbon fiber panels can make and cut.

Hobbycarbon carbon fiber sheets are made from 100% pure carbon fiber, size 500*600mm, thickness 0.5-30mm, also customized any size carbon fiber plate for your required. Best quality and cheap price, MOQ 1pcs

Our cut products include drone frame, racing car racks, wallets, belt buckles, mobile phone cases, key chains, business cards, logos, auto parts, medical and electronic accessories. The carbon fiber application field is very broad, customers from different fields are welcome to consult and OEM your products.

Product Features

Excellent performance, high precision and reliability are our pursuit. With a number of highly trained and experienced engineers, anytime are ready to provide technical support to our customers.

We can provide the best service in the shortest time, just waiting you a call or an email.

Application

Our services includes cutting carbon fiber sheets according to your DXF or STEP files.

We supply carbon fiber cutting service with 7 sets CNC machines that offer an accuracy up to 0.05 mm. Thanks to rich experience we offer cutting service of different carbon fiber products, Such as:

1.automated machine arms and robotics

2.fpv drone frame, RC model parts, Helicopters Model Drone

3.Decoration parts for Car, jewelry and furniture

4.Manufacture fixtures and tooling

5.cell phones, portable computers

6.high-end Sports equipment

7.Musical instruments

8.Scientific apparatus

9.Medical device.

If you want to cut carbon fiber keyboard, please send inquiry or email info@hobbycarbon.com. We will offer you the best quality and cheap price.

Our service also including painting, edge rounding and chamfering. After cutting carbon fiber process, all carbon fiber parts with uniform edge and aesthetic appearance, looks modern and high-tech just what you want.

We are carbon fiber sheets manufacturer, welcome to sample order to test and checking hobbycarbon carbon fiber quality. Mixed samples are acceptable.

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for testing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing.

Product detail pictures:

Related Product Guide:

In the automotive industry, carbon fiber sheets are used to strengthen automotive components such as doors, hoods, bumpers, fenders and roof rails. Automakers often use steel to make these parts. Although less expensive, steel is much heavier than carbon fiber. To make vehicles such as race cars lighter, carbon fiber sheets are often used to replace many steel parts. 2021 Latest Design Carbon Fiber Uses In Construction - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi , The product will supply to all over the world, such as: venezuela, London, Sri Lanka, Carbon fiber tube, also known as carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated and cured by pultrusion (twisting).Carbon fiber tubes have the advantages of high strength, long life, corrosion resistance, light weight and low density, and are widely used in kites, aircraft models, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, small thermal expansion coefficient, self-lubrication, energy absorption and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance and so on. The advantage is that it has very good tensile strength (for example, calculated in units of 12,000 filaments, its tensile strength is kg/mm2—400).

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!