2021 wholesale price Cnc Cutting - T700/T300 3K Full Carbon Fiber Sheet – Feimoshi

2021 wholesale price Cnc Cutting - T700/T300 3K Full Carbon Fiber Sheet – Feimoshi Detail:

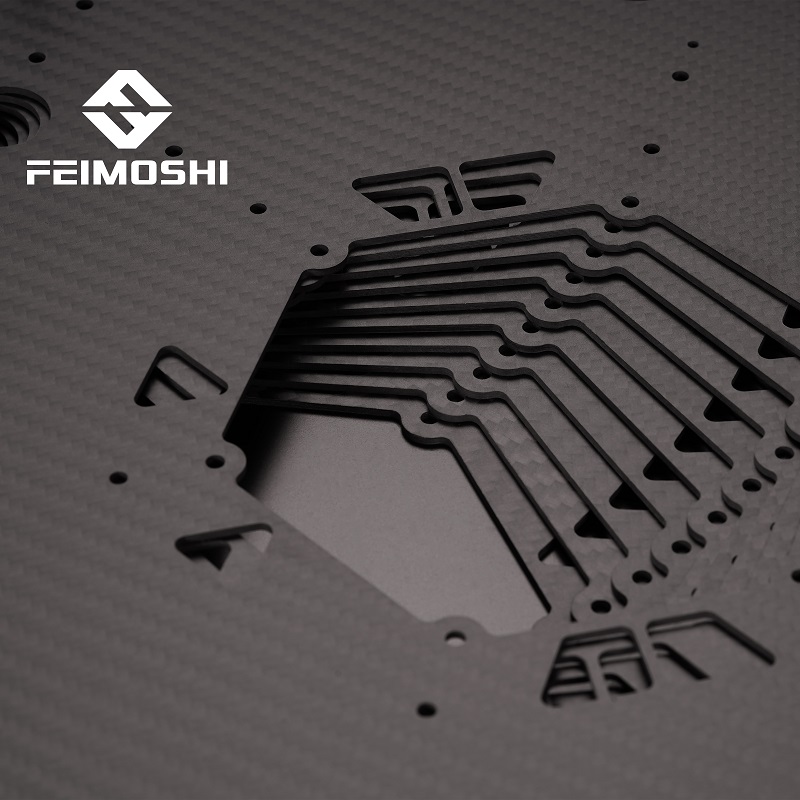

T700 3K Full Carbon Fiber Sheet

T700S is the highest tensile strength, standard modulus carbon fiber available in the industry. Standard modulus carbon fibers are available in tow sizes from 1K to 24K.

3K is recognized as the most delicate surface for fpv frames.

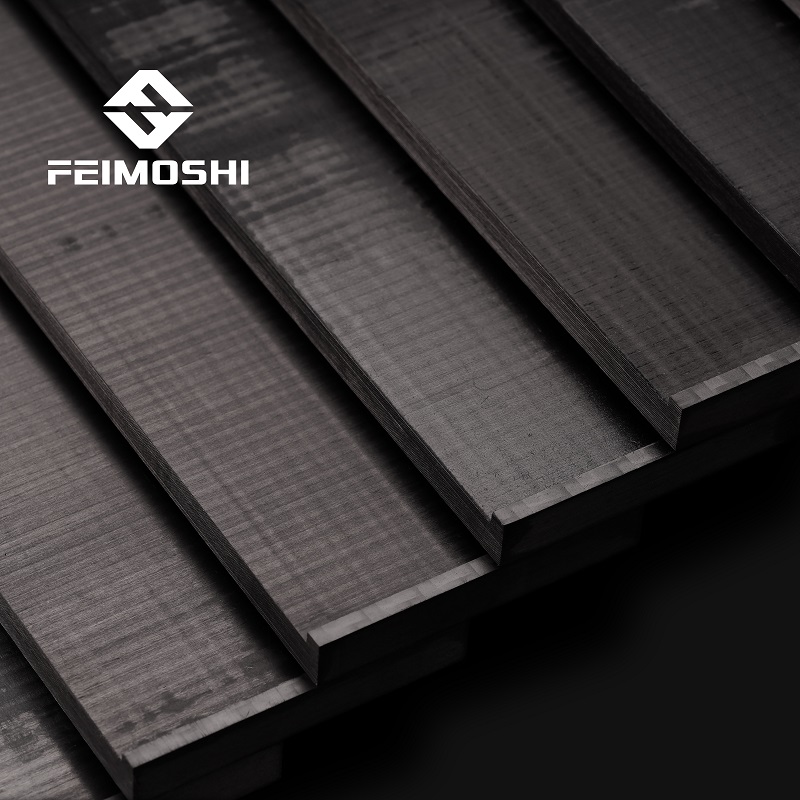

Our normal stock of sheets including full Carbon Fiber Sheets, Carbon Glass Sheet and G10 Glass Fiber Sheet.

T700 carbon fiber plate, toray carbon fiber, 3k carbon fiber sheets ,Carbon Fiber Sheet Product one of the most pouplar sheets.

Our normal stocked type is Toray T300 full carbon fiber sheet, carbon fiber tube, CNC cutting service, OEM/ODM and logo service.

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

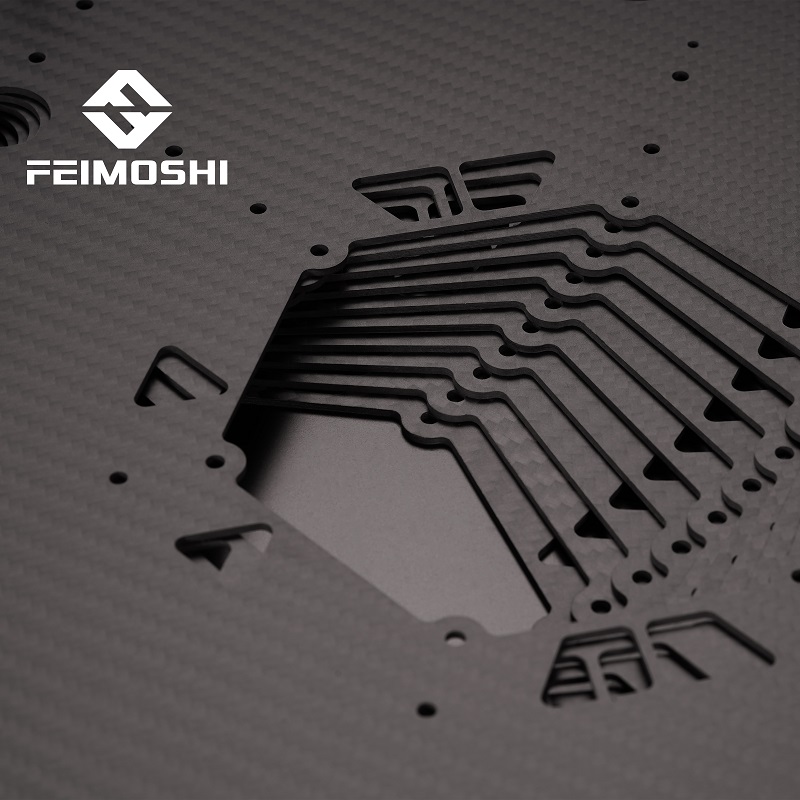

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for tesing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing.

Looking for ideal T700 Carbon Fiber Plate Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Toray Carbon Fiber are quality guaranteed. We are China Origin Factory of 3k Carbon Fiber Sheets. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

In recent years, the demand for carbon fiber has maintained a steady upward trend, and enterprises and investment institutions are also optimistic about the development prospects of the carbon fiber industry. What's new. At the same time, the carbon fiber industry has a wide range of applications, and its M&A demand and activity are also very obvious. 2021 wholesale price Cnc Cutting - T700/T300 3K Full Carbon Fiber Sheet – Feimoshi , The product will supply to all over the world, such as: Ethiopia, Sao Paulo, Luxemburg, In general, grinding and filing can grind the edges of sharp carbon fiber boards to a smooth appearance. However, if the fiberboard is exposed to harsh environments for a long time, such as marine environments, a two-part epoxy laminate is used to seal the edges.According to the different divisions of carbon fiber precursors, there are generally pitch-based carbon fiber cloth, PAN-based carbon fiber cloth, and viscose-based carbon fiber cloth.Second, according to different specifications, it can be divided into 1K, 3K, 6K, 12K and 24K and above carbon fiber cloth.Third, according to different carbonization, it can also be divided into graphitized carbon fiber cloth, (this carbon fiber cloth can withstand high temperature of 2,000 to 3,000), carbon fiber cloth (can cope with high temperature of about 1,000 degrees), and pre-oxidized carbon fiber cloth (can Resist the high temperature of 200~3 Baidu).Fourth, according to different manufacturing methods, subsequent divisions can be performed. Woven carbon fiber cloth, generally two-dimensional cloth, three-dimensional cloth and three-dimensional woven cloth, etc.; carbon fiber prepreg cloth, including dry and wet prepreg cloth; carbon fiber non-woven fabric, non-woven fabric, also known as chopped strand mat, Continuous felt, surface felt, stitched felt, etc.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!