Best quality Forged Carbon Fiber Sheet - 3k plain matte laminated carbon fiber sheet plate – Feimoshi

Best quality Forged Carbon Fiber Sheet - 3k plain matte laminated carbon fiber sheet plate – Feimoshi Detail:

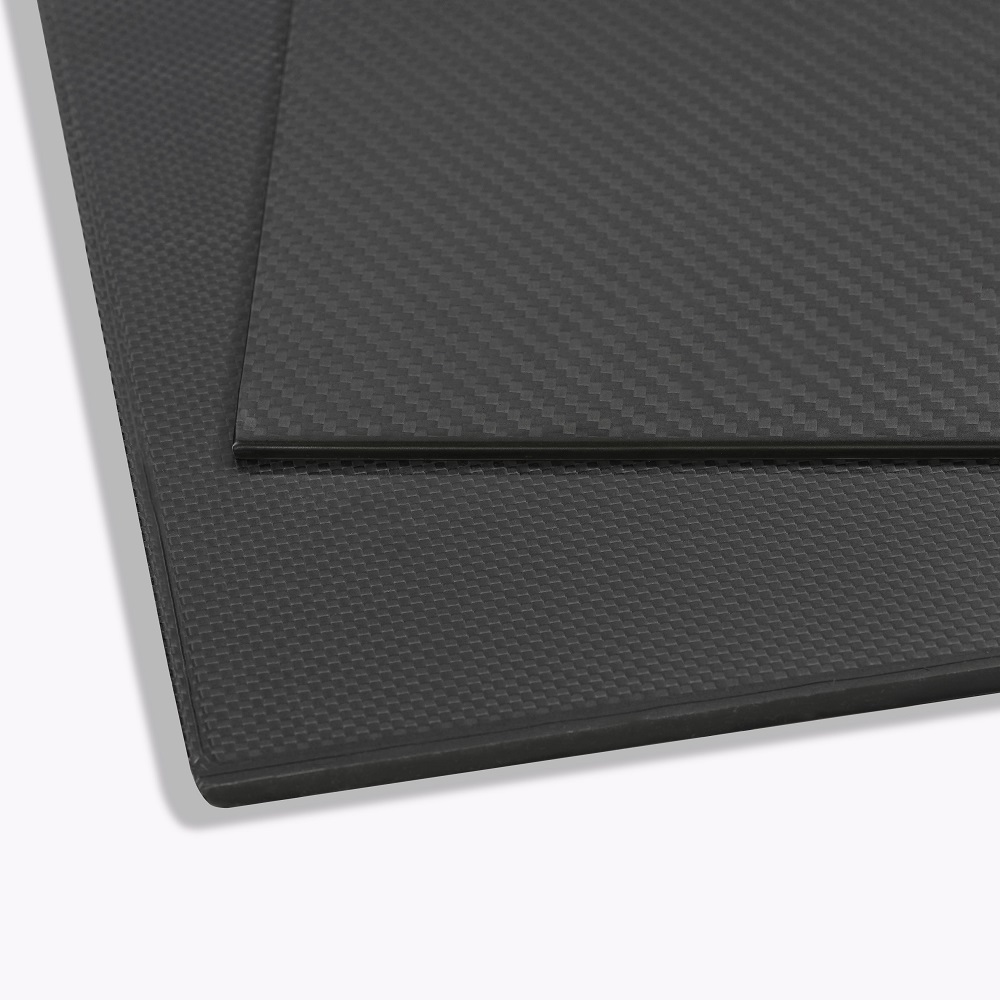

3k plain matte laminated carbon fiber sheet plate

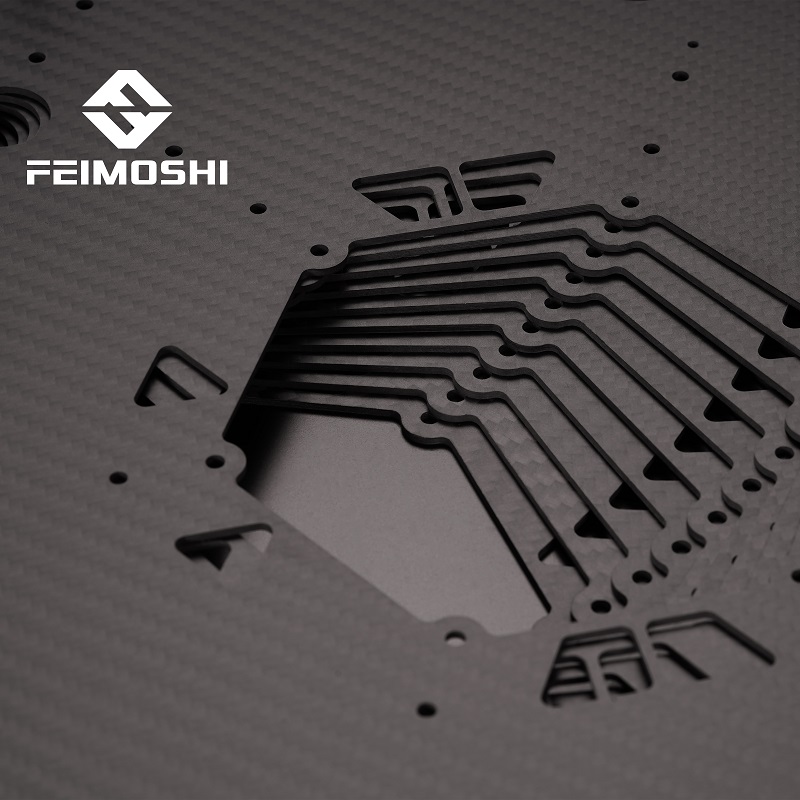

The Carbon Fiber Sheet or Carbon Fiber Plate is manufactured using 100% carbon fiber reinforcement and epoxy resin. The surface can choose from will /plain, matte/glossy. without any glass fiber contents. It is especially applicable for the FPV frame, helicopters, and RC airplanes. We are able to do Carbon Fiber CNC cutting Parts for RC Helicopter, RC cars, UAV frames, drone frames, multi-copter frames, camera gimbal frame,s or others per your specifications. Our factory use imported Japan TORAY or Taiwan TAIRYFIL carbon fiber fabric to make the carbon fiber plates/carbon fiber sheets.

Features:

1. High strength, high modulus, small density, and stable size;

2. Excellent acid, alkali, and corrosion resistance;

Product detail pictures:

Related Product Guide:

Carbon fiber and carbon fiber tube have different pressure capacity. Why are carbon fiber and carbon fiber tubes different in pressure? This is because carbon fiber is not the same as carbon fiber composite material. Carbon fiber composite material is an intermediate material that is fused with carbon fiber and resin. In terms of performance, carbon fiber is much higher than carbon fiber composite materials, but carbon fiber cannot be used as a material alone. 1. Carbon fiber pressure bearing capacity: The tensile strength of carbon fiber material is 3530MPa, 1MPa=1N/mm2, which is 3530N/mm2, which means that it can withstand a force of 3530 Newtons on a cross section of 1 square millimeter, which is 353Kg. 2. The pressure-bearing capacity of carbon fiber composite materials: the carbon fiber tube with T700 grade, 1.6mm thickness, 50mm inner diameter and 500mm length is used for testing, and the measured tensile strength is about 230MPa, that is, the cross section of 1 square millimeter bears a force of 230 Newtons , which is 23Kg. Best quality Forged Carbon Fiber Sheet - 3k plain matte laminated carbon fiber sheet plate – Feimoshi , The product will supply to all over the world, such as: Melbourne, Anguilla, Melbourne, Carbon fiber board mainly has the following characteristics:1. Light weight and high toughness. The weight of carbon fiber board is similar to that of plastic of the same volume, which is 20% of that of steel. Although it is light, its toughness is comparable to that of steel. It can be bent and coiled.2. High tensile coefficient. The tensile coefficient of carbon fiber is several times higher than that of steel, and it has good resistance to deformation, so carbon fiber boards are used in concrete reinforcement, bridge reinforcement and other places.3. Good chemical stability. Carbon fiber board base material is carbon element, carbon element has good chemical stability, and has the characteristics of corrosion resistance, acid and alkali resistance, wear resistance and so on.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.