Best-Selling Cnc Machining Carbon Fiber - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi

Best-Selling Cnc Machining Carbon Fiber - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi Detail:

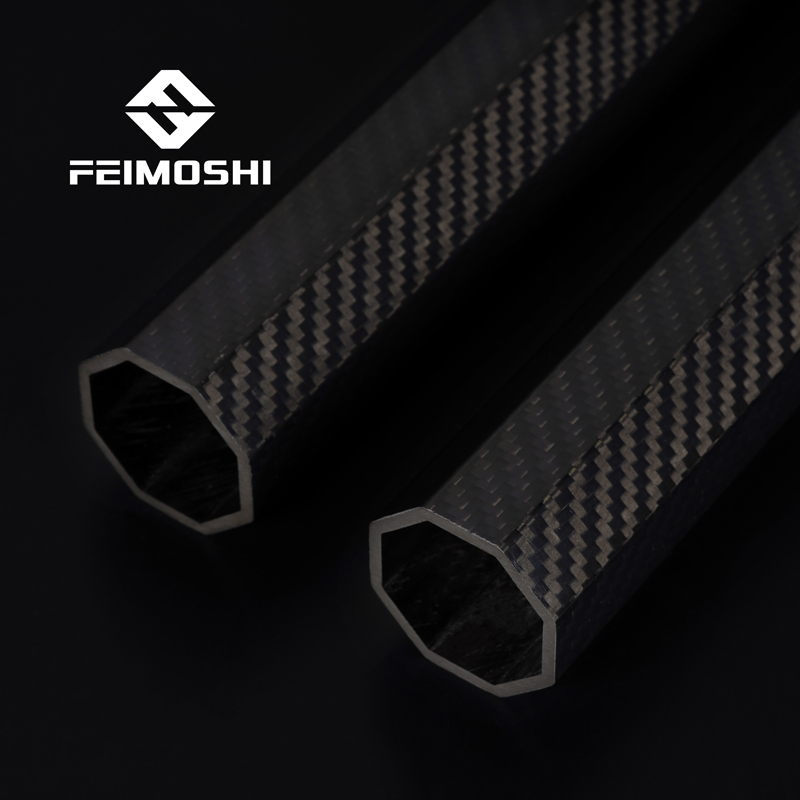

DIY 3K large diameter Carbon fiber round/square rod boom

Product Description

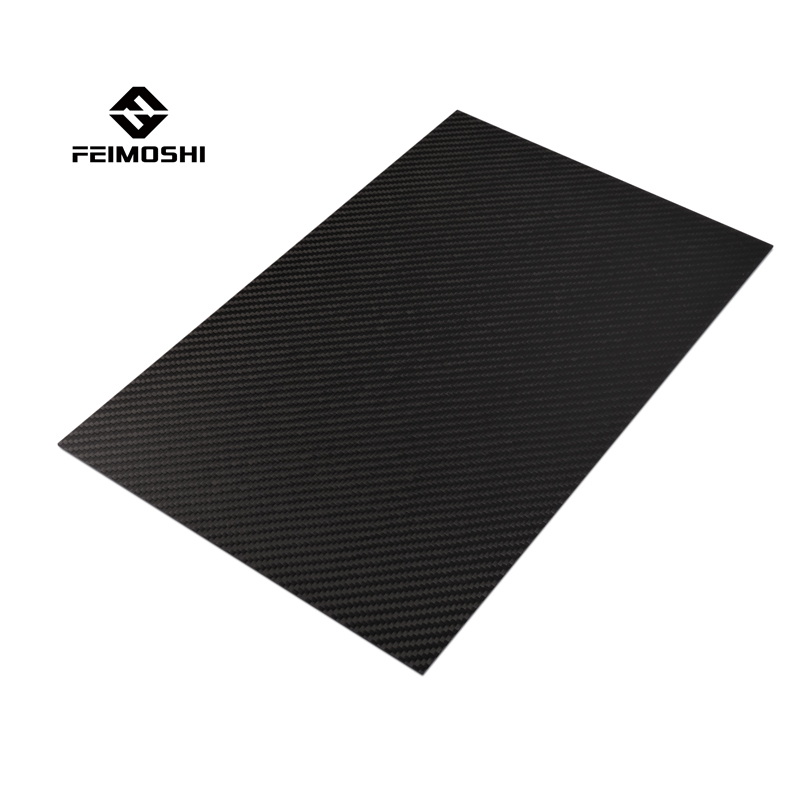

Our Carbon Fiber Tube is great performance and appearance. Made from attractive pattern plain twill or as customer requirement.

We make the Carbon Fiber Tubes by rolling-Wrapped process. It makes the carbon fiber tube much stronger and professional. More and more customers choose the full carbon fiber tube to make the drone arm, desk leg, gimbal stand and so on. And you could offer your creative ideal, we could help you to come ture. Carbon fiber tube is also widly used in building construction. It makes them much lighter and easy to move.

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness:1.0mm/1.5mm/2.0mm

Length: longest length is 2000mm

Appearance: 3K twill weave, plain weave, or other

Looking for ideal Carbon Fiber carbon fiber tube Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Epoxy Resin Carbon Fiber 3k Woven are quality guaranteed. We are China Origin Factory of Carbon Fiber Shape. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

1. The net weight of carbon fiber products is relatively light. The extraordinary light weight allows industrial equipment to operate at lower power, saving resources. Best-Selling Cnc Machining Carbon Fiber - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi , The product will supply to all over the world, such as: UAE, Juventus, Luxembourg, With the improvement of the production process, carbon fiber board will popularize or replace many metal structural materials, providing the possibility for the lightness and convenience of products.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.