High Quality Composite Tube - Customize DIY carbon fiber drone tube – Feimoshi

High Quality Composite Tube - Customize DIY carbon fiber drone tube – Feimoshi Detail:

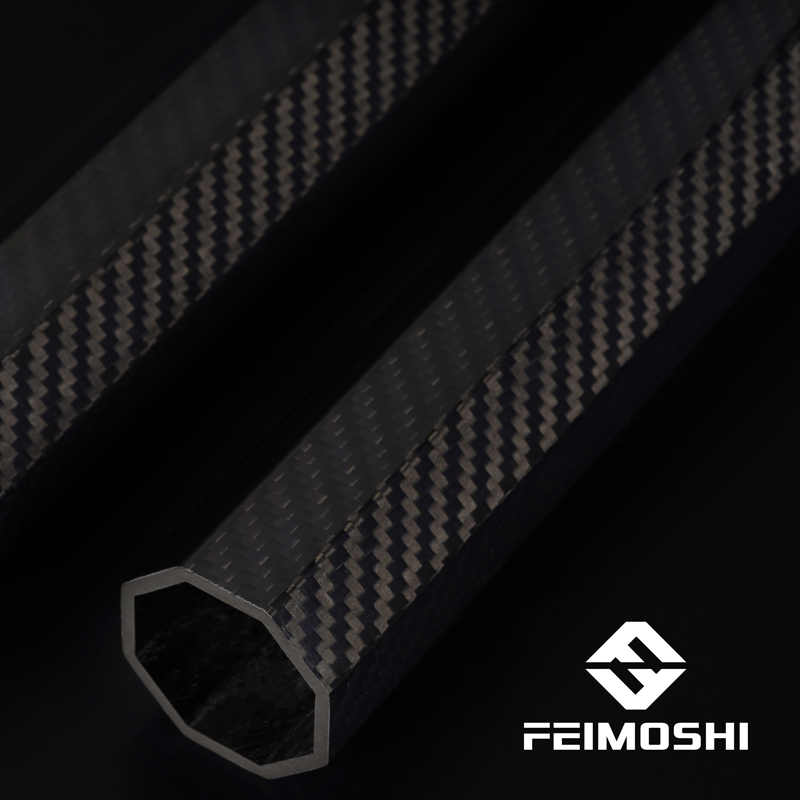

Shape: Customize DIY carbon fiber drone tube

Raw Materials: Toray T300 3K twill matte Carbon Fiber

Performance: High-Strength and Light-Weight

Supply Type: In-Stock Items(Various size and different length)

Material: 100% Carbon Fiber/Full carbon fiber

Weight: 0.1-1kg

Feature: Abrasion-Resistant, Waterproof, Anti-Static

Thinckness: 1.0mm/1.5mm/2.0mm/3.0mm….10.0mm/20.0mm/30.0mm

Length: Longest Length Is 2000mm

Payment Type: T/T,Paypal,Western Union

Appearance: 3K twill weave, plain weave, or other

Finish: Glossy, matt, natural Techniques: Rolling-wrapping Advantage: High-Strength, light weight, Corrosion Resistant etc.

Recently, we have Octagon carbon fiber tube, round carbon fiber boom, curved carbon fiber tube and square carbon fiber tube in stock. These moulds are made by us. We could do

Looking for ideal Carbon Fiber Bicycle Tubing Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Diy Carbon Fiber Tubing are quality guaranteed. We are China Origin Factory of Flexible Carbon Fiber Tubing. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fibers are generally not used alone, but in the form of composite materials. Composite material refers to a new type of material with certain special functions and structures formed by combining two or more materials. The material composition can be generally understood as matrix material + reinforcement material, among which the matrix material is mostly resin, ceramic, metal, Rubber and other materials, the reinforcing material is often glass fiber or carbon fiber. High Quality Composite Tube - Customize DIY carbon fiber drone tube – Feimoshi , The product will supply to all over the world, such as: Finland, Cyprus, Morocco, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.