Bottom price Carbon Fiber Plate In Stock - Twill glossy custom cnc carbon fiber part – Feimoshi

Bottom price Carbon Fiber Plate In Stock - Twill glossy custom cnc carbon fiber part – Feimoshi Detail:

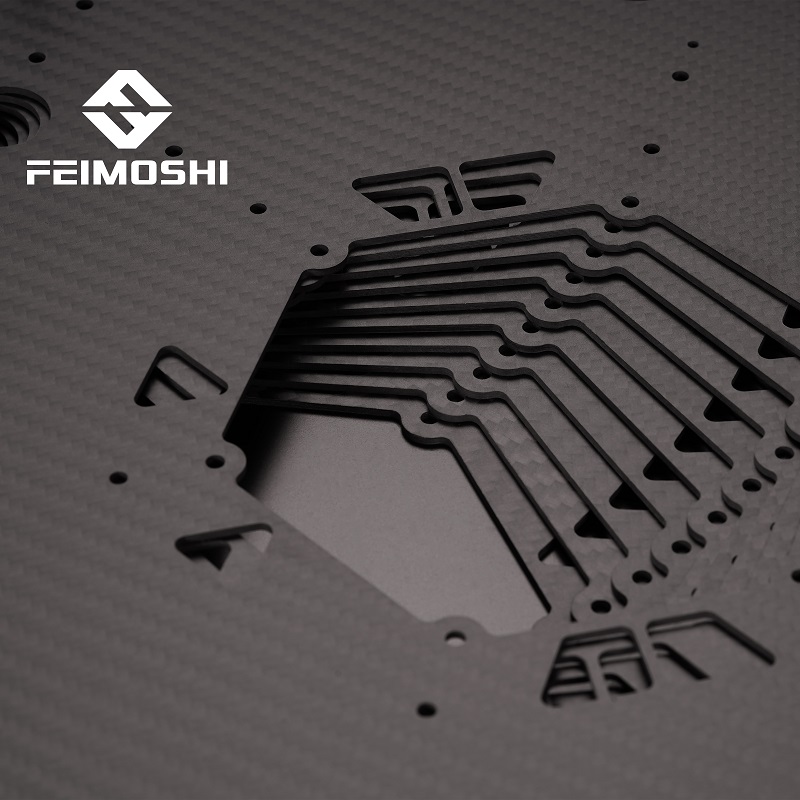

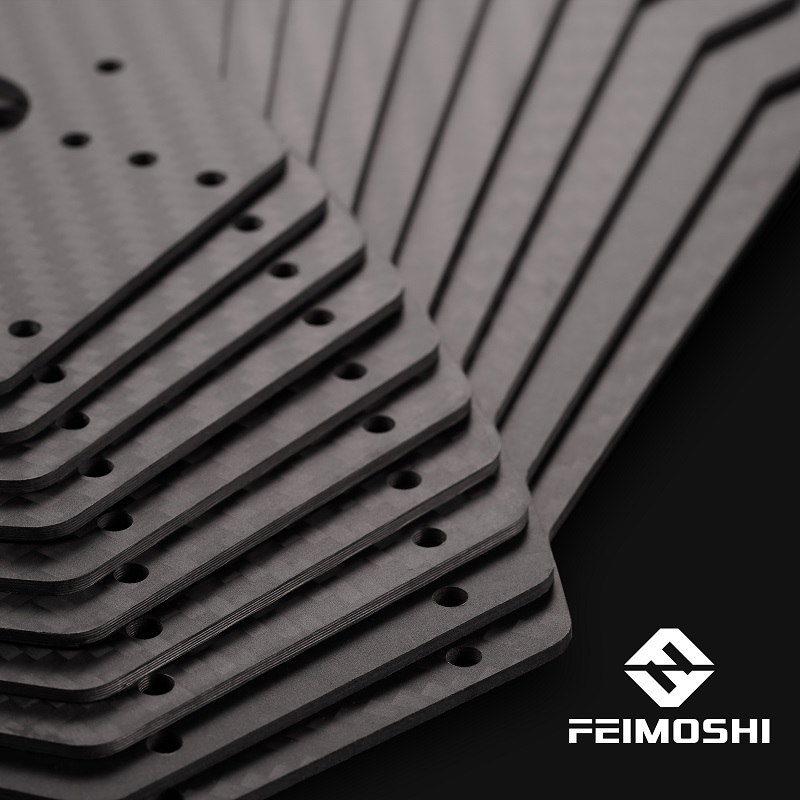

Twill glossy custom cnc carbon fiber part

Description:

Hobbycarbon is a professional manufacturer of carbon fiber products for more than 10 years. We have our own CNC maching.

Not only we can produce full carbon fiber plate, we also can use carbon fiber board to cut the shape required by the customer.

Before we quote, let me know quantity, thickness and send us drawing. (3D or 2D)

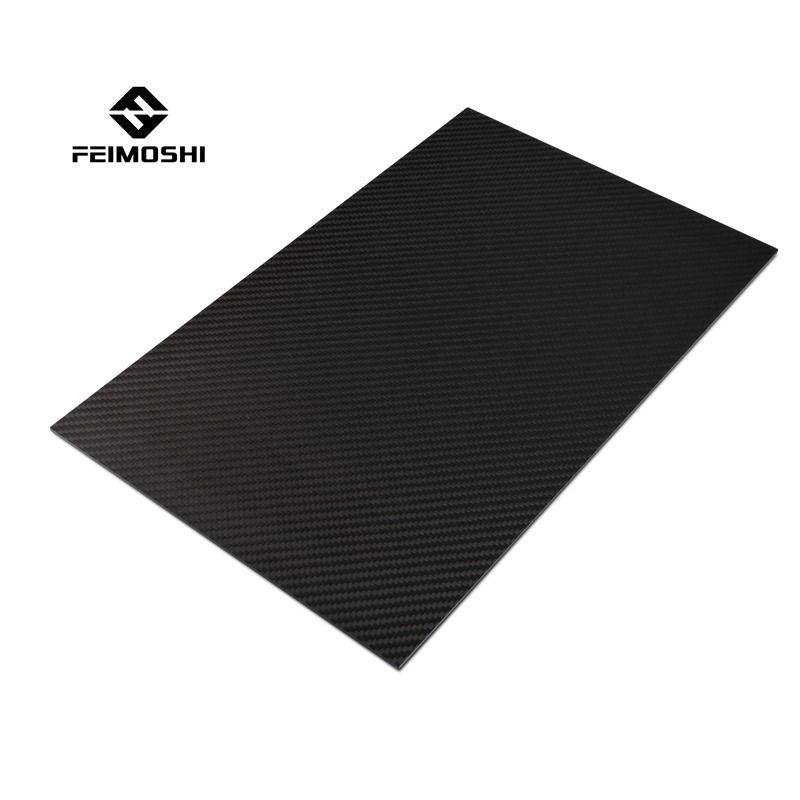

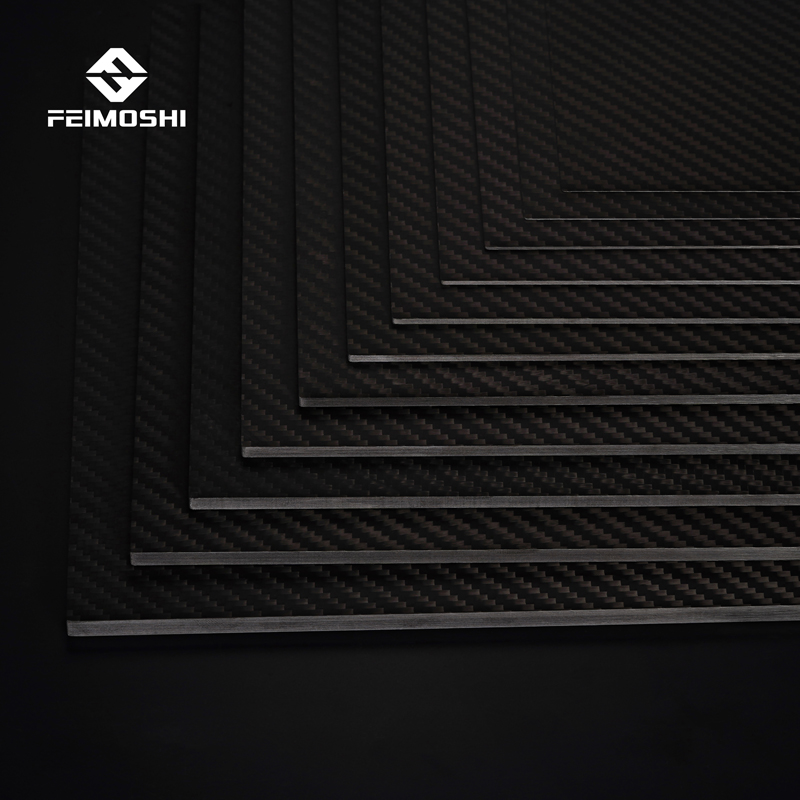

Size: regular size is 400x500mm/500x600mm (other size also is ok)

Thickness: 0.3mm-20mm

Weave: Plain/ Twill

Surface: Glossy/ Matte

Payment way: Paypal, Bank

Delivery time: 3-7 working days

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Bottom price Carbon Fiber Plate In Stock - Twill glossy custom cnc carbon fiber part – Feimoshi , The product will supply to all over the world, such as: Nairobi, Canada, Switzerland, Carbon fiber board mainly has the following characteristics:1. Light weight and high toughness. The weight of carbon fiber board is similar to that of plastic of the same volume, which is 20% of that of steel. Although it is light, its toughness is comparable to that of steel. It can be bent and coiled.2. High tensile coefficient. The tensile coefficient of carbon fiber is several times higher than that of steel, and it has good resistance to deformation, so carbon fiber boards are used in concrete reinforcement, bridge reinforcement and other places.3. Good chemical stability. Carbon fiber board base material is carbon element, carbon element has good chemical stability, and has the characteristics of corrosion resistance, acid and alkali resistance, wear resistance and so on.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

Send your message to us:

Write your message here and send it to us