Bottom price Carbon Fiber Plate In Stock - Twill glossy custom cnc carbon fiber part – Feimoshi

Bottom price Carbon Fiber Plate In Stock - Twill glossy custom cnc carbon fiber part – Feimoshi Detail:

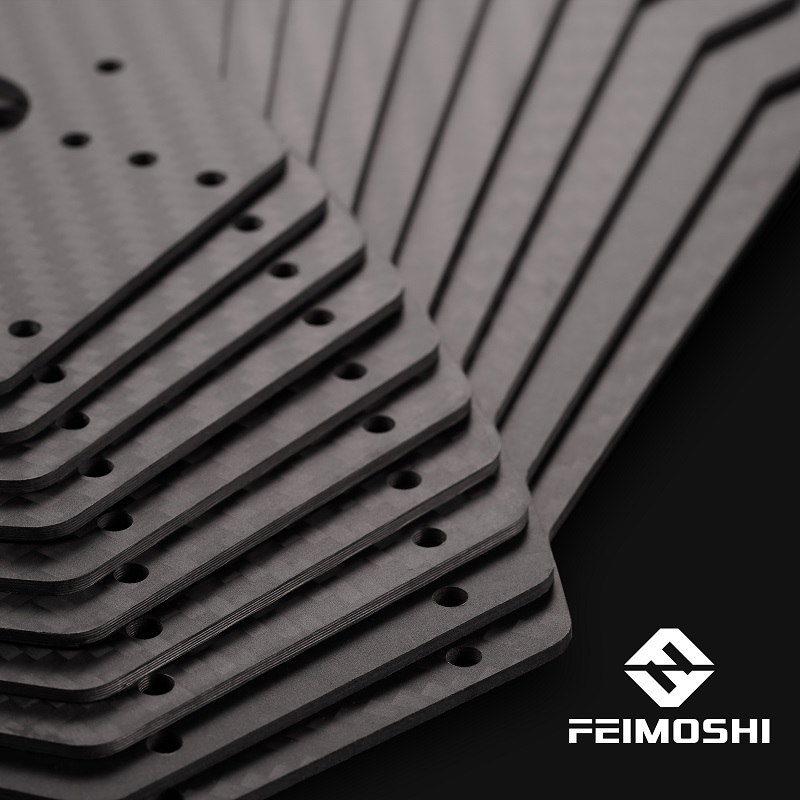

Twill glossy custom cnc carbon fiber part

Description:

Hobbycarbon is a professional manufacturer of carbon fiber products for more than 10 years. We have our own CNC maching.

Not only we can produce full carbon fiber plate, we also can use carbon fiber board to cut the shape required by the customer.

Before we quote, let me know quantity, thickness and send us drawing. (3D or 2D)

Size: regular size is 400x500mm/500x600mm (other size also is ok)

Thickness: 0.3mm-20mm

Weave: Plain/ Twill

Surface: Glossy/ Matte

Payment way: Paypal, Bank

Delivery time: 3-7 working days

Product detail pictures:

Related Product Guide:

In recent years, the demand for carbon fiber has maintained a steady upward trend, and enterprises and investment institutions are also optimistic about the development prospects of the carbon fiber industry. What's new. At the same time, the carbon fiber industry has a wide range of applications, and its M&A demand and activity are also very obvious. Bottom price Carbon Fiber Plate In Stock - Twill glossy custom cnc carbon fiber part – Feimoshi , The product will supply to all over the world, such as: Ottawa, Iraq, Jamaica, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

Send your message to us:

Write your message here and send it to us