Cheapest Price Custom Carbon Fiber Machining - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi

Cheapest Price Custom Carbon Fiber Machining - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi Detail:

Lightweight phone case carbon fiber shockproof and anti-drop

Below is the newest iPhone 13 cases:

1. Material: Kevlar Fiber

2. Technology: Vacuum Pumping by Autoclave equipment

3. Weight: as light as you thought

4. MOQ: 10pc

5. Matte surface, no sweats, no fingerprints;

6. 4-side protection, camera lens protection;

7. Excellent grip, no loose;

8. 1:1 precise cutouts for ports and buttons;

9. Like a skin, keep the original beauty/feeling of the device

Why do we use aramid fiber, but don’t use carbon fiber?

Aramid fiber is commonly used in aerospace and performance automotive industries, as it is exceptionally durable and lightweight.

Different from carbon fiber, aramid fiber does not affect your phone’s signal (Wi-Fi, GPS, and cell reception), making it the ideal material for phone cases.

Using vacuum forming technologies, we can mold aramid fiber into a multitude of designs while maintaining its strength and protective qualities.

Product detail pictures:

Related Product Guide:

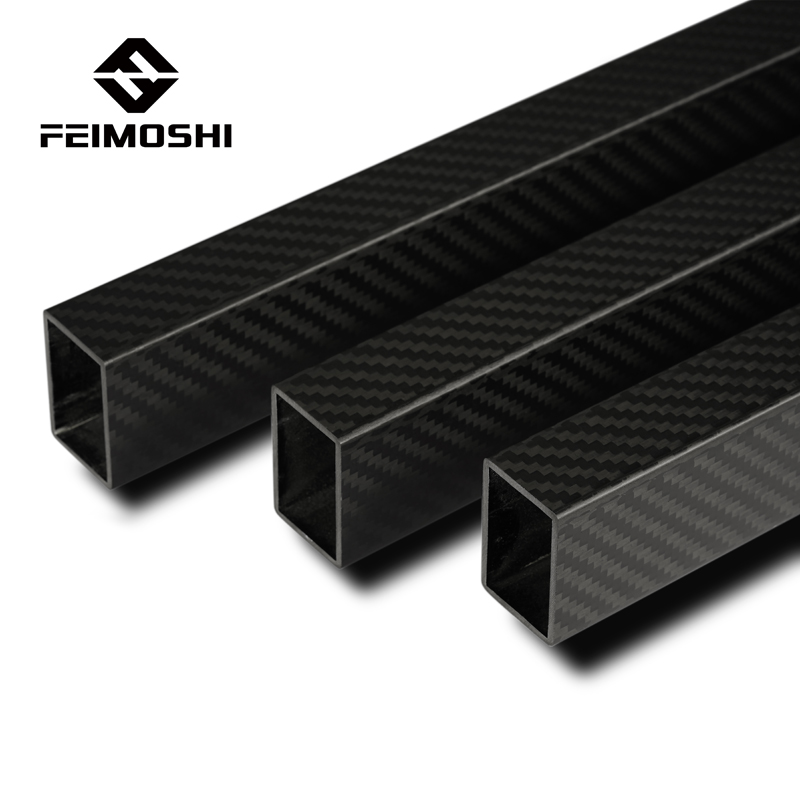

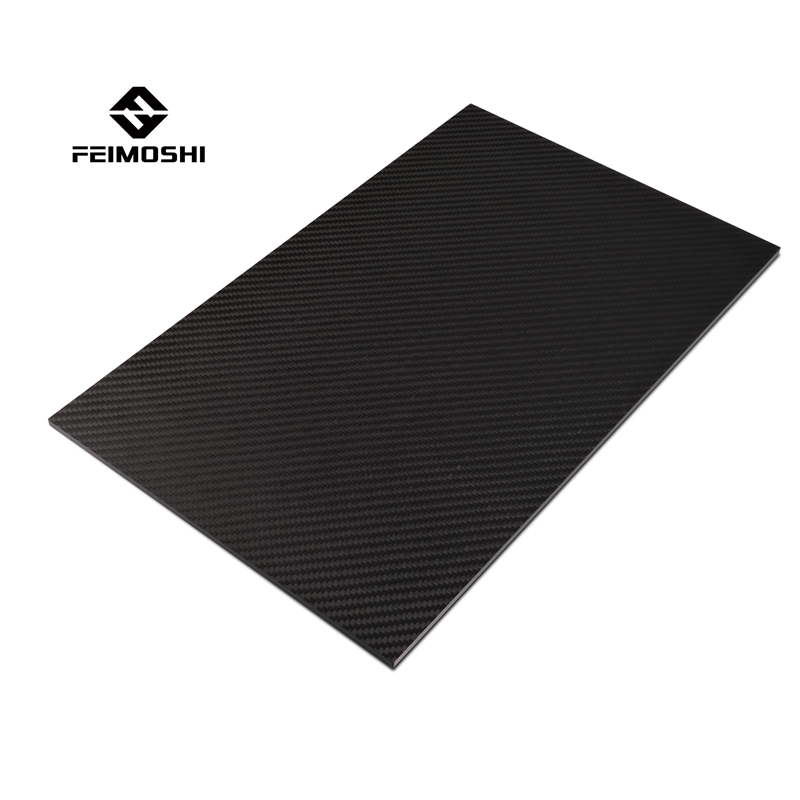

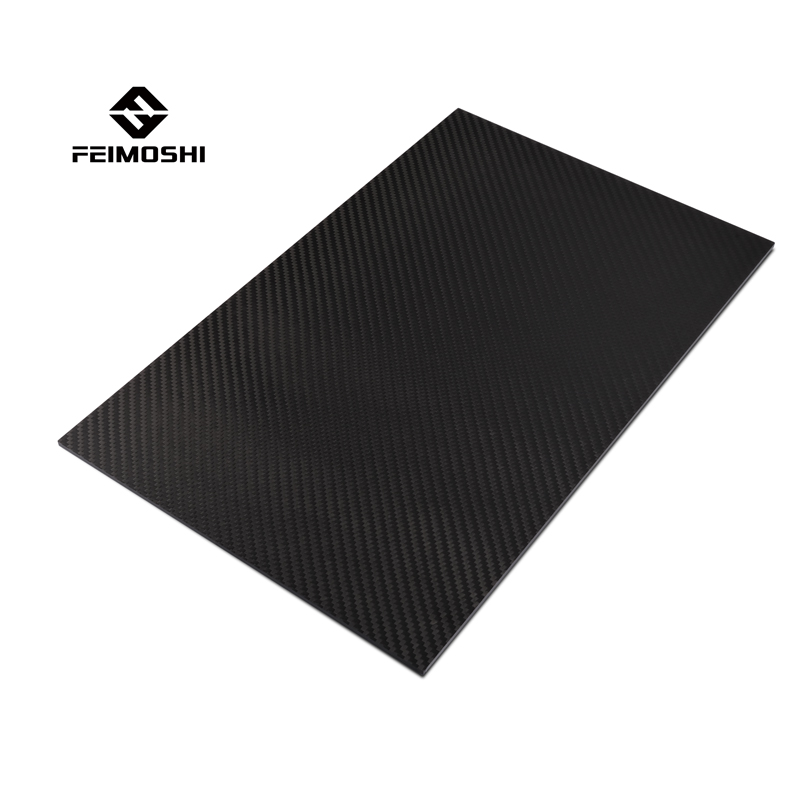

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. Cheapest Price Custom Carbon Fiber Machining - Lightweight phone case carbon fiber shockproof and anti-drop – Feimoshi , The product will supply to all over the world, such as: Toronto, Madagascar, Swaziland, There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.