China Cheap price 3k Composite Plate - Racing Car 3k carbon fiber Panel – Feimoshi

China Cheap price 3k Composite Plate - Racing Car 3k carbon fiber Panel – Feimoshi Detail:

Carbon fiber material is more popular in RC field due to the beautiful surface and light weight.

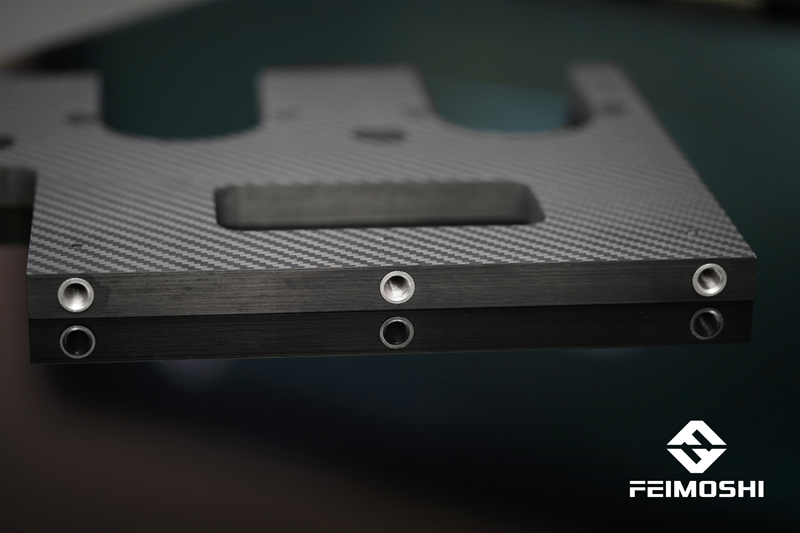

Maybe someone need to inistall screws, it not a problem, we could install a special nut to match. (see below picture)

But it have thickness requirement. If it is too thin, the nut cannot be installed.

Description:

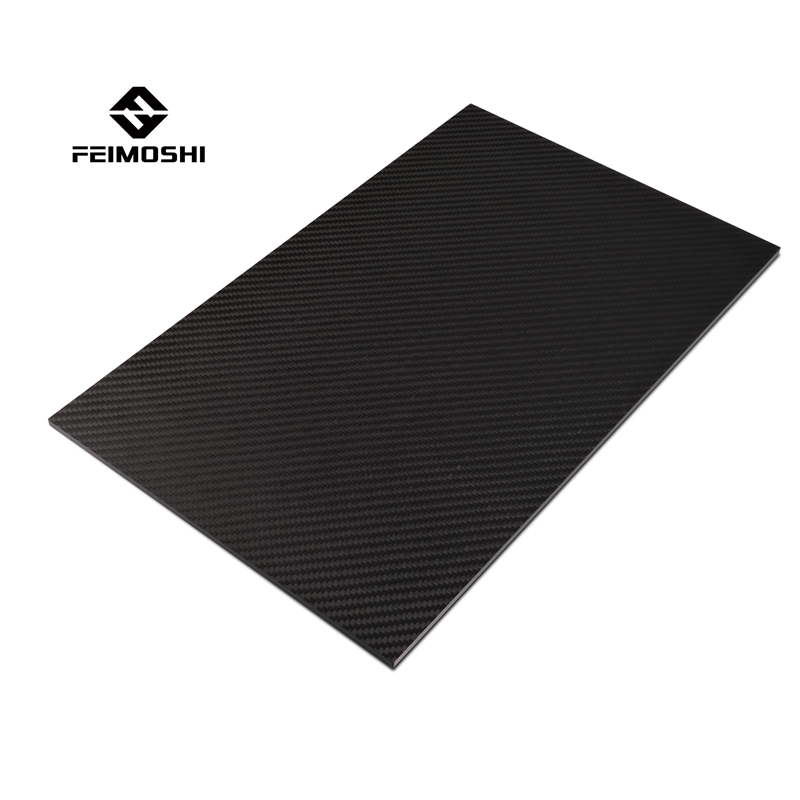

Product name: Racing Car 3k carbon fiber Panel

Size: 400x500mm/ 500x600mm is our regular size, customize other size also is ok

Thinkness: 0.3mm-20mm

Weave: Plain/Twill

Surface: Gloosy/ Matte

Service: CNC carbon fiber cutting, customized service

FAQ

1. More than 10 years experience,you will get pleased service on time.

2. 100% inspection on critical dimensions with high accuracy +/-0.02-0.2mm

3. Factory direct price and fast delivery on time

4. Sample is available

5. OEM&ODM orders are welcome

*Drawings, photos and samples are welcome.

*We can produce the products as to your requirement or samples. Special for your own.

* Please contact us freely if there is any question.

*We are looking forward to having good cooperation with you.

*Welcome to FMS!

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. China Cheap price 3k Composite Plate - Racing Car 3k carbon fiber Panel – Feimoshi , The product will supply to all over the world, such as: Bolivia, Ukraine, Uruguay, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.