China Cheap price Carbon Fiber Cutting Part - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi

China Cheap price Carbon Fiber Cutting Part - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi Detail:

Why choose Autoclave phone case?

Easy to use even with complex curvature of the product

Zero voids.

Perfect appearance of the carbon fiber fabric.

Excellent fatigue resistance.

Laminate thickness keeped under control.

The process is clean.

The process offers better quality as well as conformity.

Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max Protective Cases – aramid Bullet-Proof Material – Wireless Charging Capable – Slim, Drop Protection – Textured, Non-Scratch Shell

Why choose Aramid/Kevlar fibers?

High strength

Good resistance to abrasion

Good resistance to organic solvents

Non-conductive

No melting point

Low flammability

Good fabric integrity at elevated temperatures

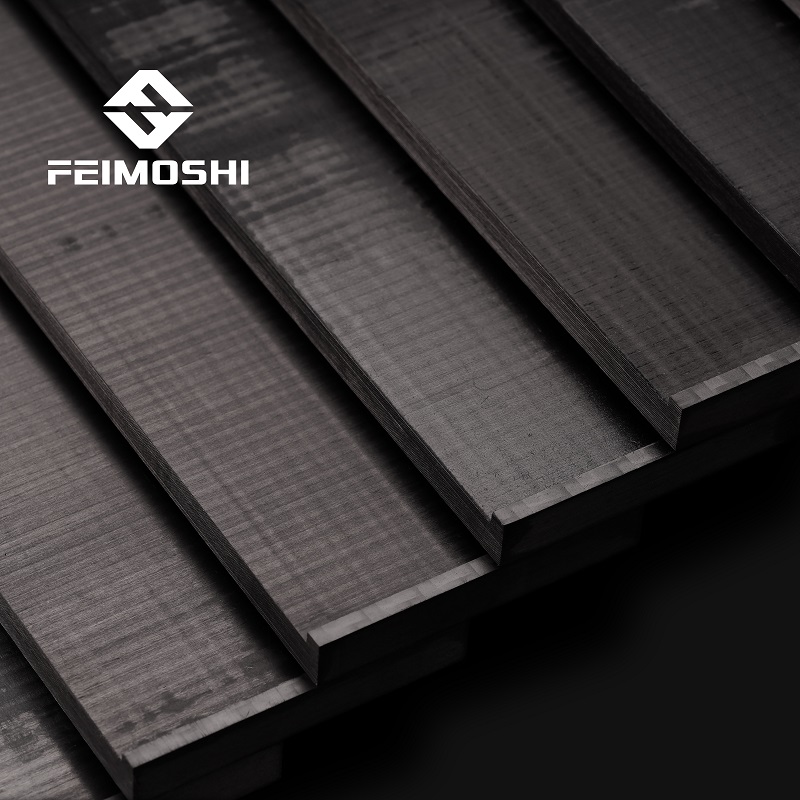

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. China Cheap price Carbon Fiber Cutting Part - Autoclave kevlar Phone Case Compatible with iPhone 13mini, iphone 13, phone 13 pro & 13 pro max – Feimoshi , The product will supply to all over the world, such as: Hungary, venezuela, Jakarta, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

Send your message to us:

Write your message here and send it to us