China wholesale Carbon Fiber Plate - 0.5mm twill weave carbon fiber laminate sheet – Feimoshi

China wholesale Carbon Fiber Plate - 0.5mm twill weave carbon fiber laminate sheet – Feimoshi Detail:

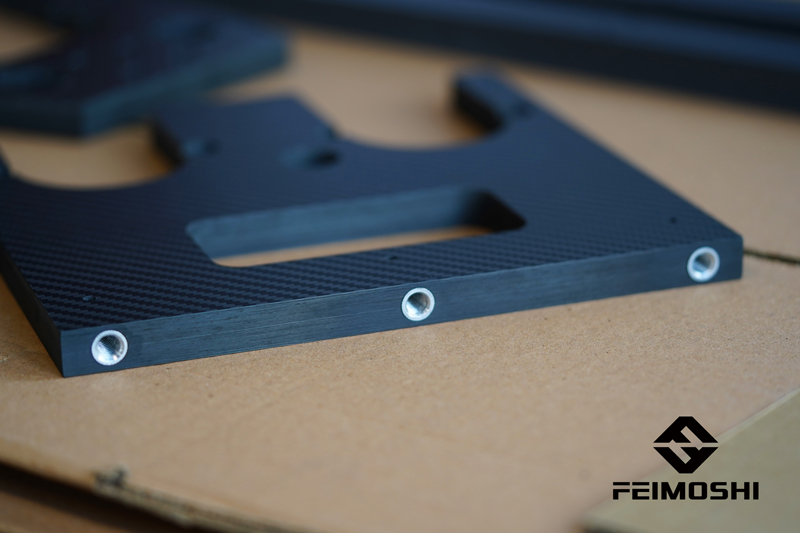

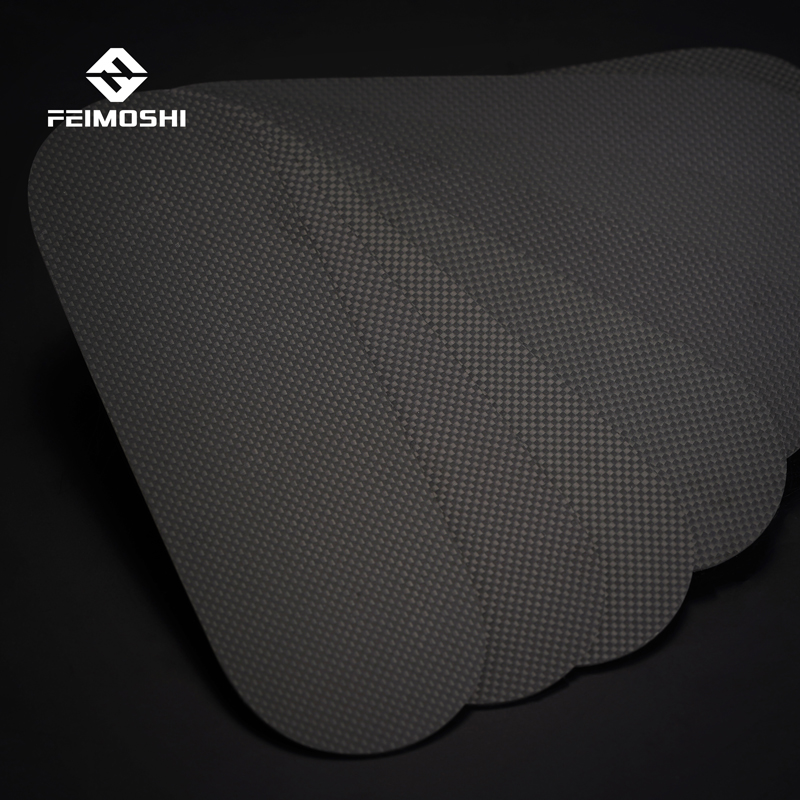

0.5mm twill weave carbon fiber laminate sheet

Carbon fiber is a kind of special fiber mainly composed of carbon elements, and its carbon content varies with different types, generally more than 90%. Carbon fiber has the characteristics of general carbon materials, such as high temperature resistance, friction resistance, electrical conductivity, heat conduction and corrosion resistance, etc. However, different from general carbon materials, its shape is significantly anisotropic, soft, and can be processed into various fabric. The fabric exhibits high strength along its direction. Carbon fiber has a small specific gravity, so it has a high specific strength.

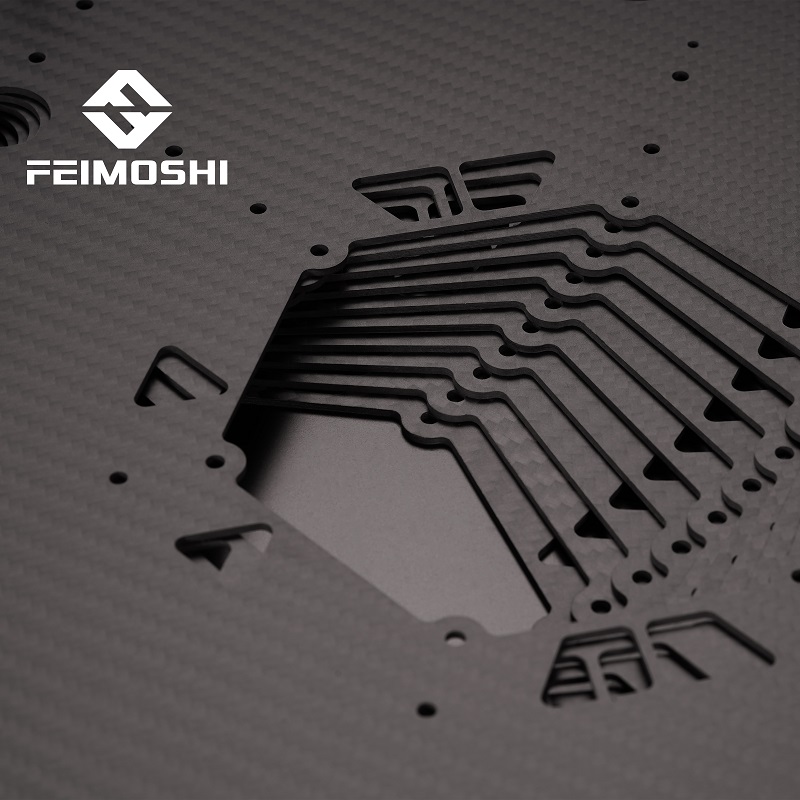

CNC Carbon Fiber Cutting is a special way to help customers get the unique frame to produce their drones in the market. We made many cooperation with many popular brand and also get more and more good feedback.

Feature: 100% 3K Carbon Fiber Strong Strength and Light Weight. Perfect for any application including RC, drones, helicopters, etc. The surface is cross grain, matte surface without any glass fiber contents. It is specially applicable for Multicopter, Helicopter and RC airplanes.

Looking for ideal Twill Weave Carbon Fiber Laminate Sheet Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 0.5mm Twill Carbon Fiber Laminate Sheet are quality guaranteed. We are China Origin Factory of 0.5mm Carbon Fiber Laminate Sheets. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. China wholesale Carbon Fiber Plate - 0.5mm twill weave carbon fiber laminate sheet – Feimoshi , The product will supply to all over the world, such as: New York, Bolivia, Hanover, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.