Chinese Professional Hexagon Carbon Fiber Tube - custom 15mm 3K twill matte carbon fiber tubes – Feimoshi

Chinese Professional Hexagon Carbon Fiber Tube - custom 15mm 3K twill matte carbon fiber tubes – Feimoshi Detail:

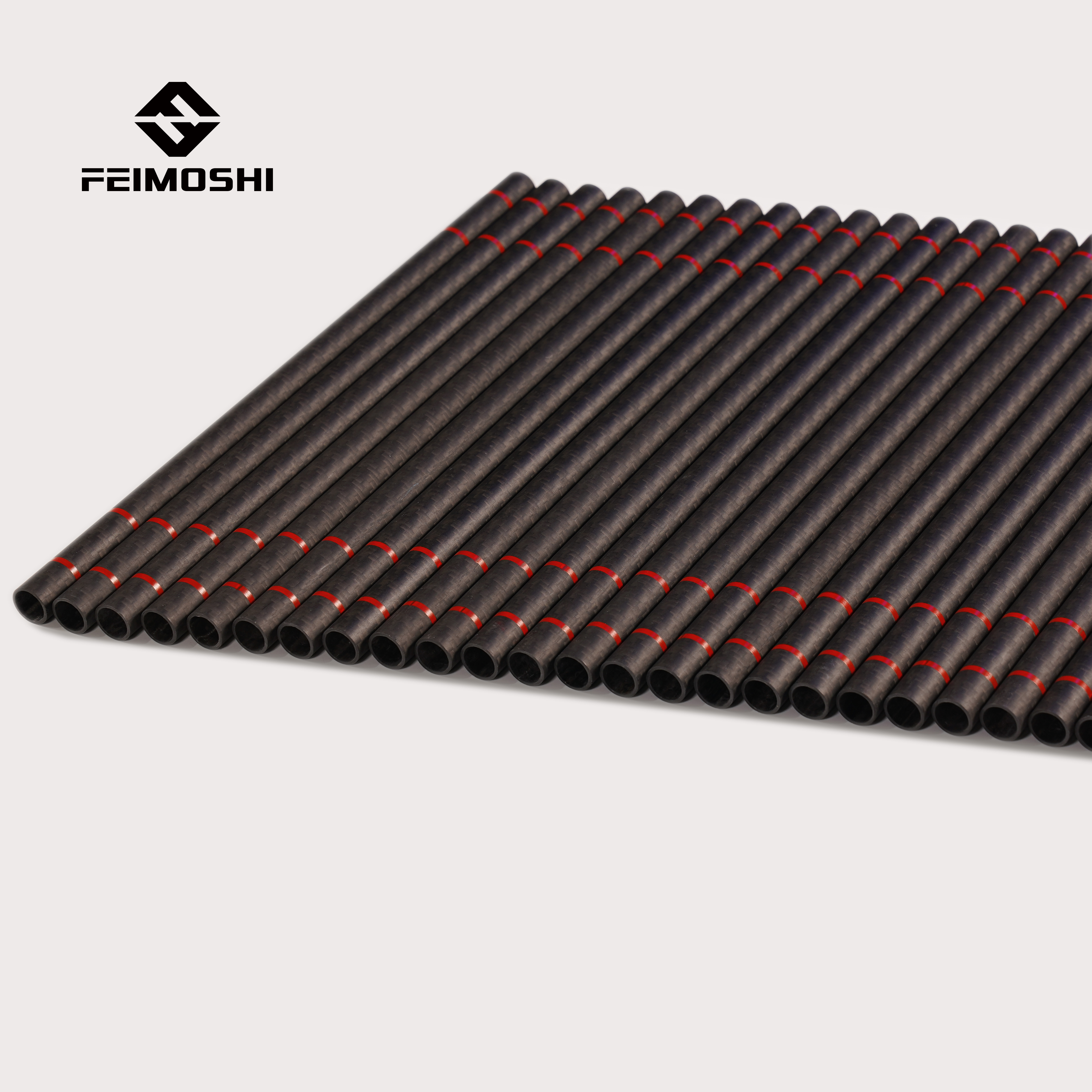

custom 15mm 3K twill matte Carbon Fiber Tubes

Carbon tube/pipe features:

1. Introduction

These 3K Carbon Fiber Tube are made of pure carbon fiber with beautiful twill or plain weave; Available in different colors and sizes( usually 3K twill matte); Customized Round carbon fiber tubes specs are accepted,like Outer Diameter :6mm,8mm,10mm,12mm,14mm,16mm20mm,22mm,25mm,30mm……350mm;

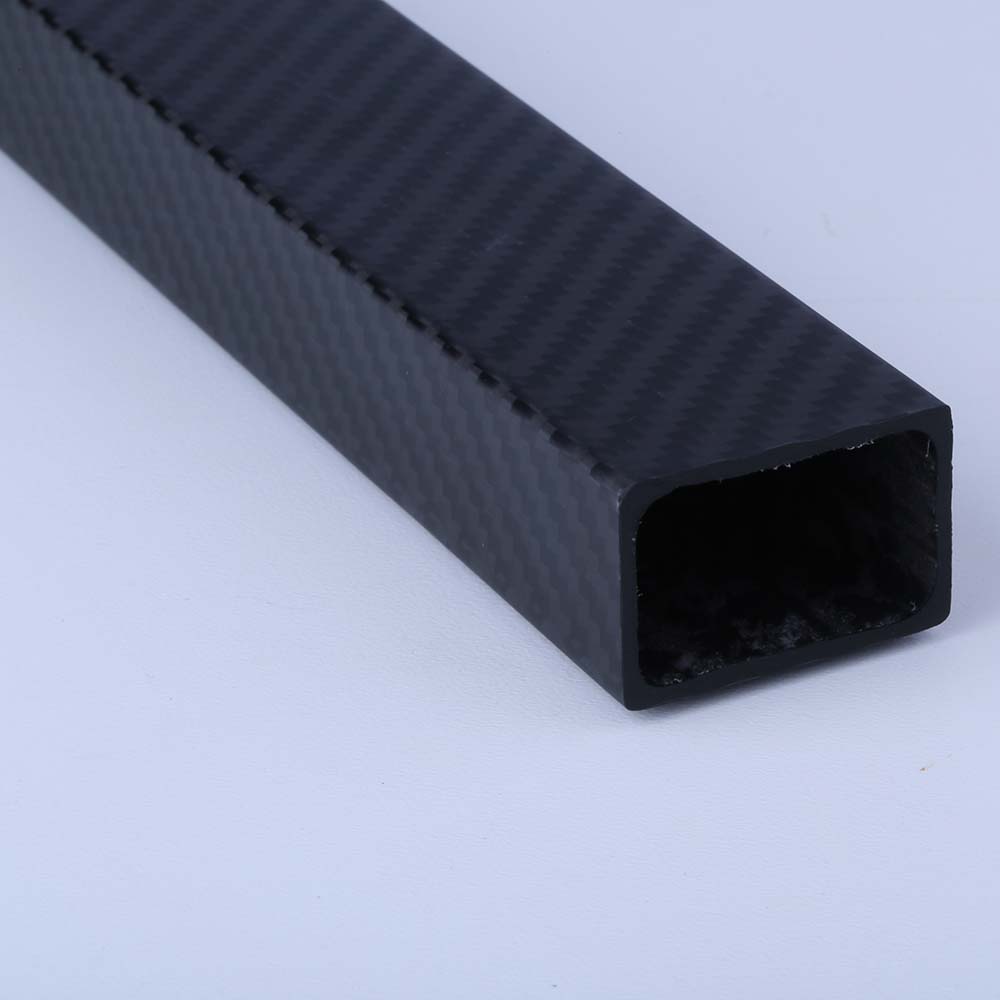

Customized Shaped Full Carbon Fiber Tube: such as: 20X30mm, 30X30mm or others. Thickness: 1.0mm, 1.5mm, 2.0mm or other thickness.

Square carbon fiber tube: 10X10mm, 15X15mm, 18X18mm, 20X20mm, 30X30mm square carbon fiber tube(These tubes have the mould by us)

Recently we upgrade our machines to improve the carbon fiber tube precision.

Most precise tolerance shaped carbon fiber tubes for us.

2. Specifications

1) High temperature resistance carbon fiber tubes :100%carbon fiber ;

2) Light & high strength;

3) Good corrosion resistance;

The carbon fiber tube is light in weight and high in strength. It can be applied to different parts of the drone body during design and assembly, such as the arm and wing frame. Compared with aluminum alloy material, it can increase the weight reduction effect by 30%, which can improve the aircraft, endurance and increase load capacity. The carbon fiber material itself has high tensile strength, energy absorption, shock resistance, and good corrosion resistance, which also extend the service life of the UAV.

Product picture

Looking for ideal 15mm Matte Carbon Fiber Tubes Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 15mm Twill Matte Carbon Fiber Tubes are quality guaranteed. We are China Origin Factory of Custom 3K Carbon Fiber Tubes. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

At this stage, many product parts are made of carbon fiber. Most parts are not standard plate and tube products. In the application environment, there are some inclination and shape regulations. Carbon fiber composite materials have good ductility, and epoxy resin can complete various intricate shapes in the flow of the mold. At this stage, the customized industry has a very large demand for such special-shaped parts. Some customers do not understand the basic knowledge of the production and application of carbon fiber special-shaped parts. Chinese Professional Hexagon Carbon Fiber Tube - custom 15mm 3K twill matte carbon fiber tubes – Feimoshi , The product will supply to all over the world, such as: America, United Arab emirates, Jersey, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.