Excellent quality Carbon Fiber Oars - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi

Excellent quality Carbon Fiber Oars - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi Detail:

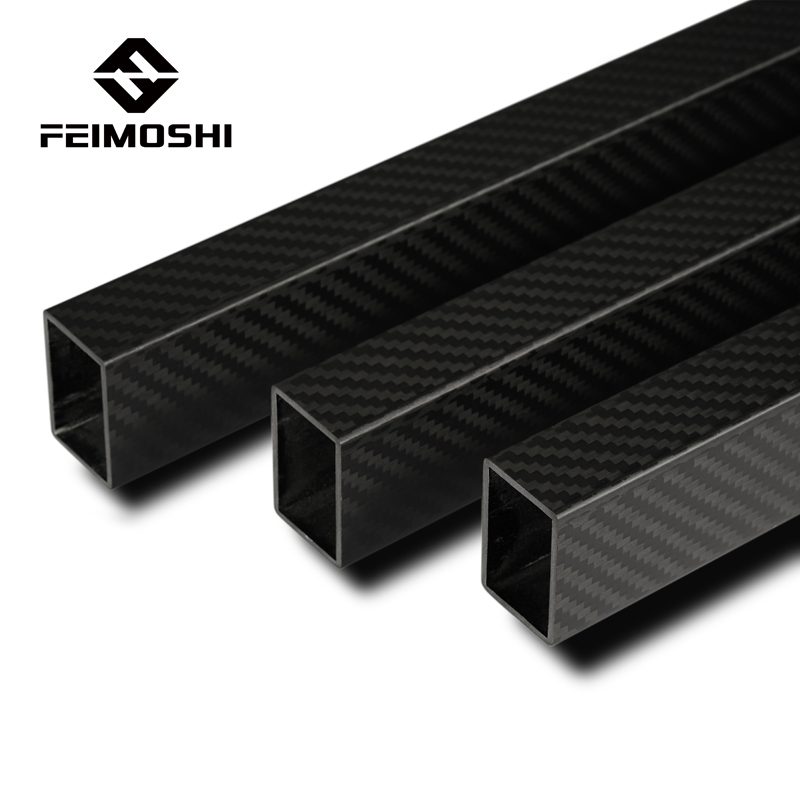

Custom Octagonal composite carbon fiber square tube for accessories

In these recent years, custom carbon fiber tube is more populare in the drone market.

Also we have carbon fiber round tube, carbon fiber octagonal tube and carbon fiber square tube in stock.

Different size and type is avaliable for your choosing.

Small carbon fiber round tube could be inserting the large carbon fiber tube according to your requirements.

Carbon fiber rectangle tube, large carbon fiber tubes, carbon fiber tube handguard, ect. are all customized according to your requirements.

If you have any other requirements, please don’t hesitate to contact us.

Product detail pictures:

Related Product Guide:

In the automotive industry, carbon fiber sheets are used to strengthen automotive components such as doors, hoods, bumpers, fenders and roof rails. Automakers often use steel to make these parts. Although less expensive, steel is much heavier than carbon fiber. To make vehicles such as race cars lighter, carbon fiber sheets are often used to replace many steel parts. Excellent quality Carbon Fiber Oars - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi , The product will supply to all over the world, such as: Indonesia, Spain, Puerto Rico, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

Send your message to us:

Write your message here and send it to us