Factory Cheap Hot Drill Composite Boom - 3K CNC carbon fiber cutting opener part for composite frame – Feimoshi

Factory Cheap Hot Drill Composite Boom - 3K CNC carbon fiber cutting opener part for composite frame – Feimoshi Detail:

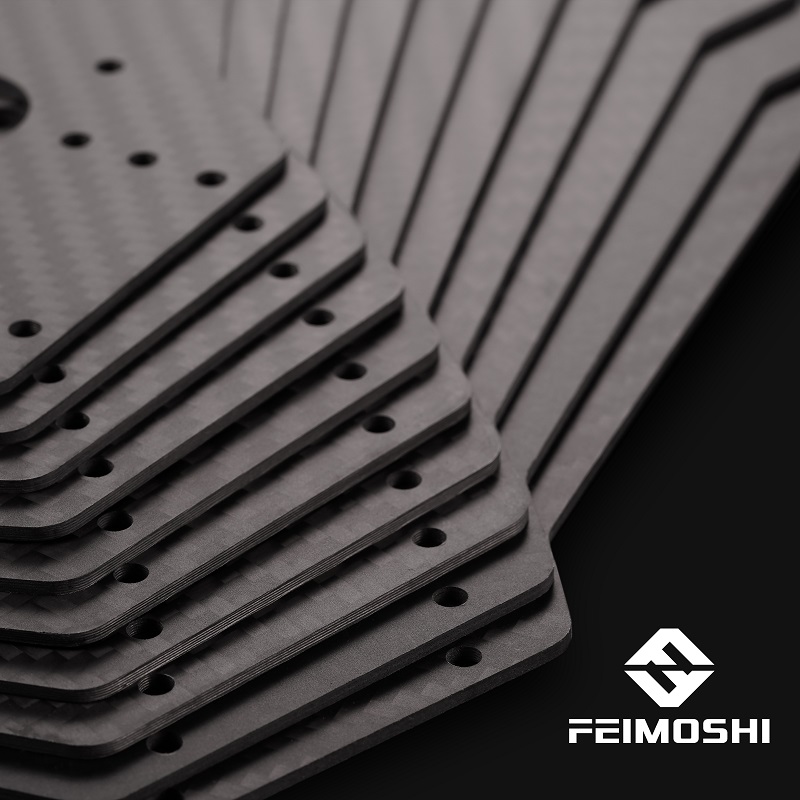

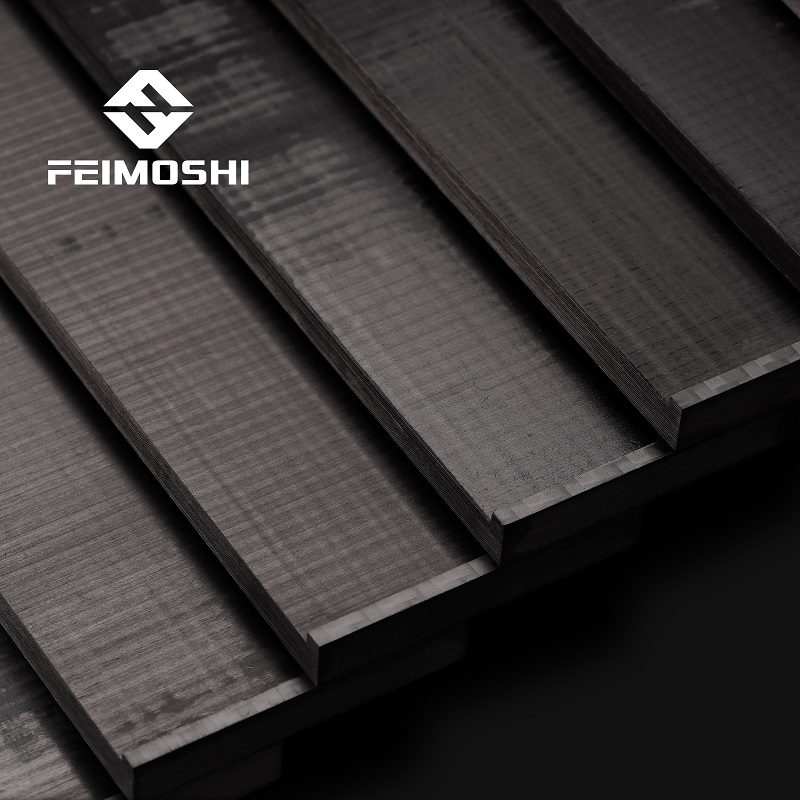

3K CNC carbon fiber cutting opener part for composite frame

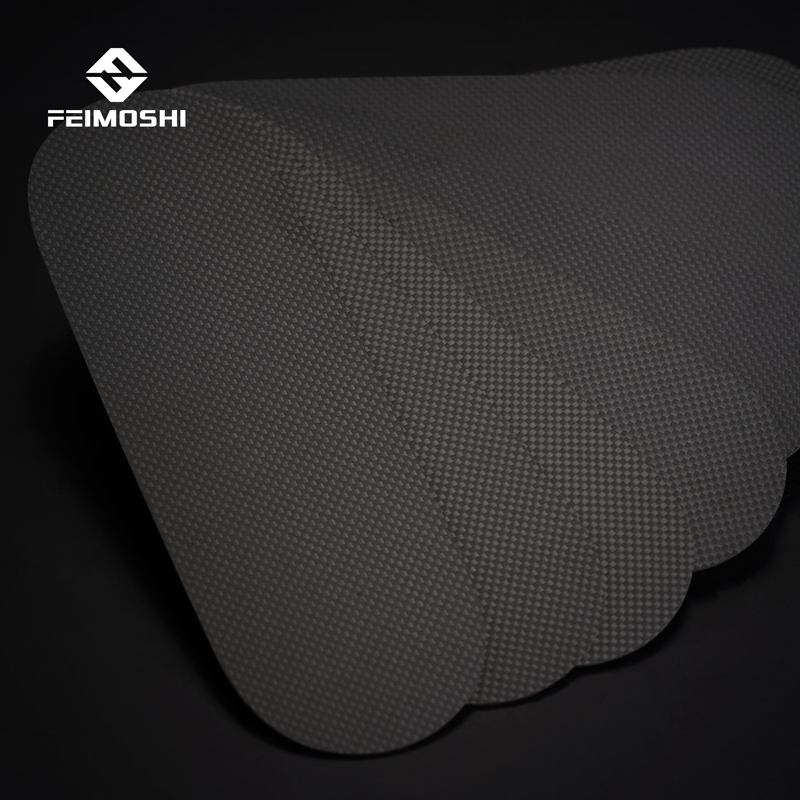

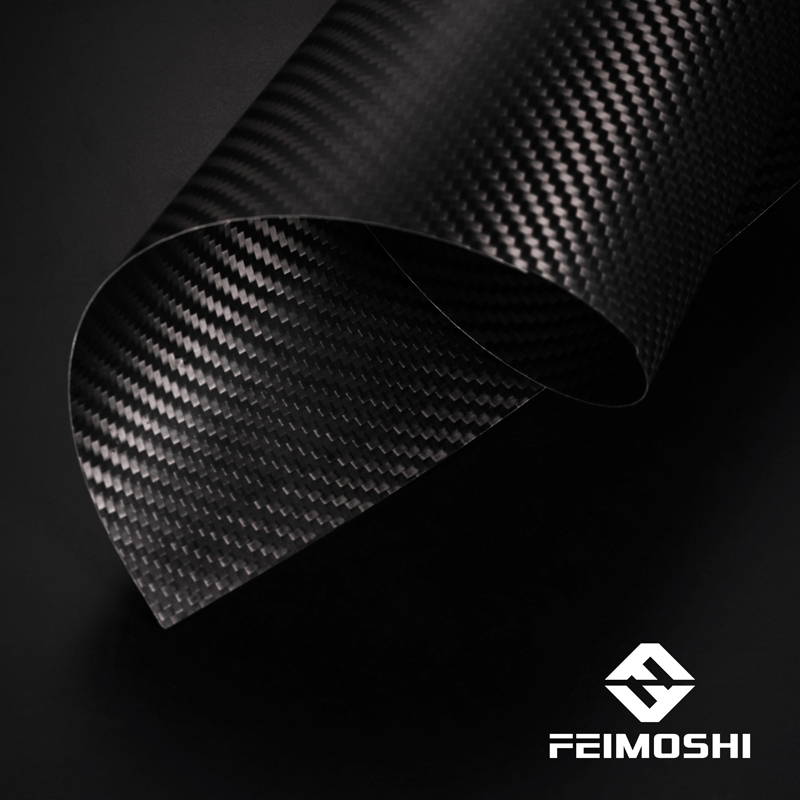

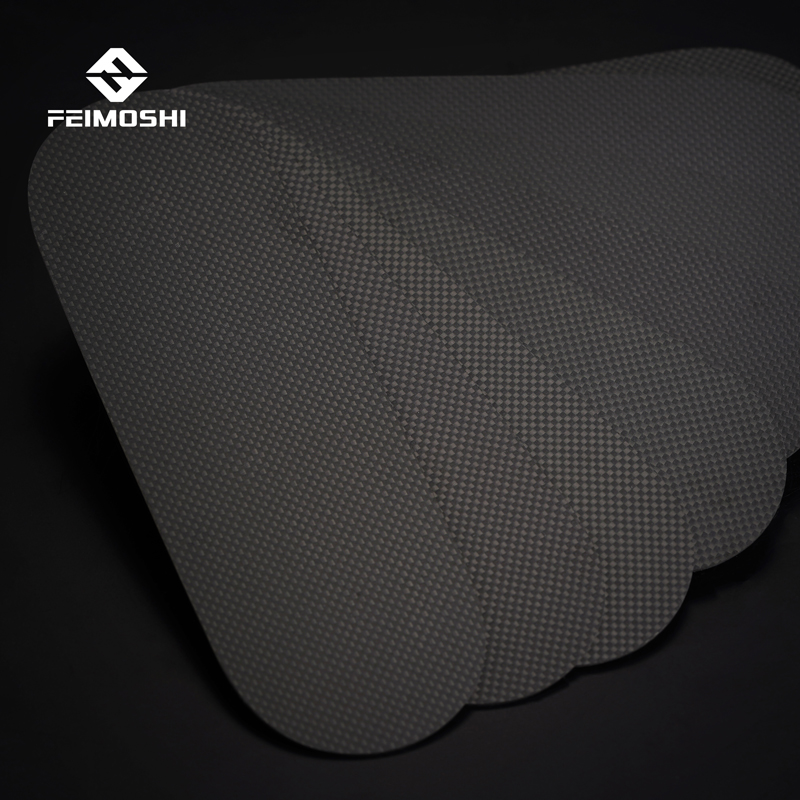

3K full carbon fiber sheet is made of carbon fiber cloth, UD cloth and eposy resin. Normally, 3K full carbon fiber plate is popular in the market. It could do many different types according to your designs.

We could help you to CNC cut the composite frame. Carbon fiber opener, carbon fiber FPV frame, carbon fiber car chassis and carbon fiber rc parts, ect. are all avaliable for us.

Also colored carbon fiber sheet, forged carbon fiber plate and carbon fiber plate with all 3K layers could be customized.

Meantime, we do many 400X500mm and 500X600mm carbon fiber plate in stock.

600X800mm, 800X1000mm and 1000X1500mm could be produced.

Do you want to do your own frame? Any interests, contact us freely.

PS: Logo service, Packing service and Assembly service are avaliable for us.

Product detail pictures:

Related Product Guide:

4. Its maintenance function is good. Carbon fiber material is waterproof, resistant to high temperature, ultra-low temperature, and abrasion, and can be used in all harsh environments. Factory Cheap Hot Drill Composite Boom - 3K CNC carbon fiber cutting opener part for composite frame – Feimoshi , The product will supply to all over the world, such as: Sierra Leone, Palestine, United Arab Emirates, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.