High definition Composite Plate Fit - 3K CNC carbon fiber cutting opener part for composite frame – Feimoshi

High definition Composite Plate Fit - 3K CNC carbon fiber cutting opener part for composite frame – Feimoshi Detail:

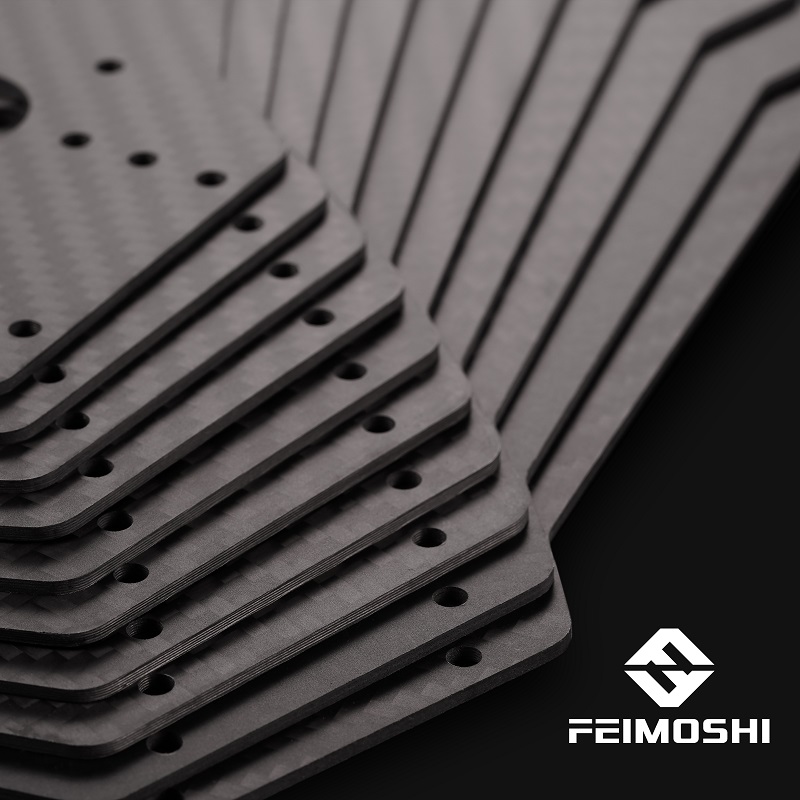

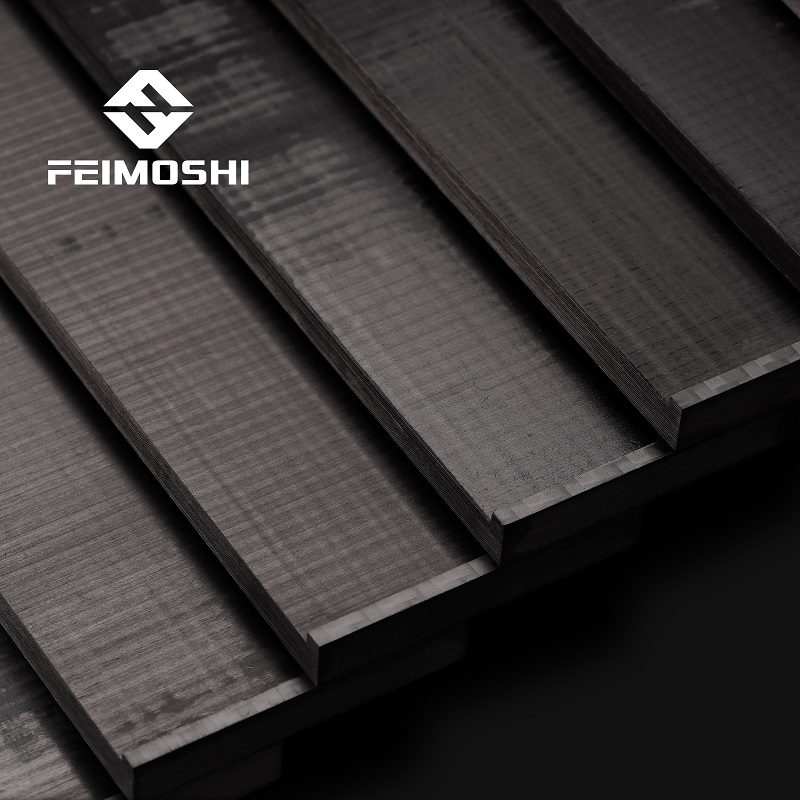

3K CNC carbon fiber cutting opener part for composite frame

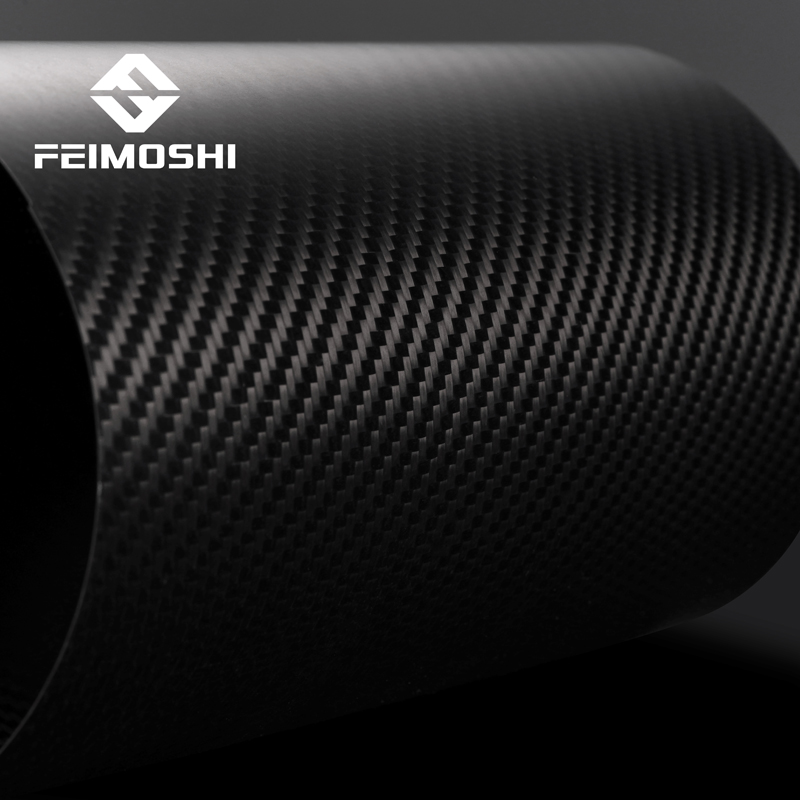

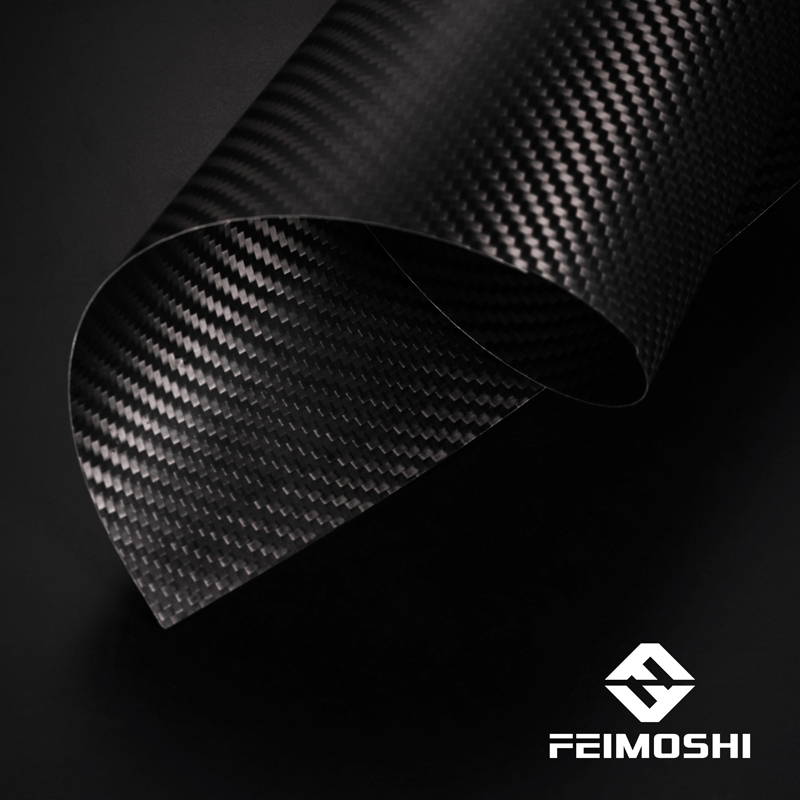

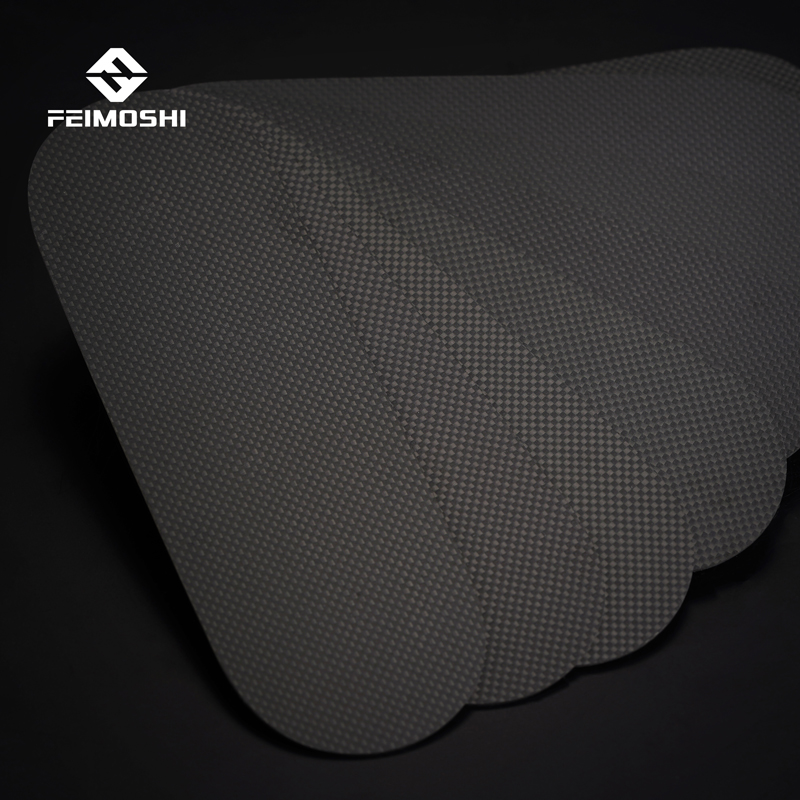

3K full carbon fiber sheet is made of carbon fiber cloth, UD cloth and eposy resin. Normally, 3K full carbon fiber plate is popular in the market. It could do many different types according to your designs.

We could help you to CNC cut the composite frame. Carbon fiber opener, carbon fiber FPV frame, carbon fiber car chassis and carbon fiber rc parts, ect. are all avaliable for us.

Also colored carbon fiber sheet, forged carbon fiber plate and carbon fiber plate with all 3K layers could be customized.

Meantime, we do many 400X500mm and 500X600mm carbon fiber plate in stock.

600X800mm, 800X1000mm and 1000X1500mm could be produced.

Do you want to do your own frame? Any interests, contact us freely.

PS: Logo service, Packing service and Assembly service are avaliable for us.

Product detail pictures:

Related Product Guide:

3. Carbon fiber material shock absorber. It is manufactured from epoxy rubber sheet and carbon fiber production, and has the original vibration damping properties of high bending stiffness raw materials. Often in the case of industrial equipment, this type of feature will quickly reduce the vibration caused by sports and fitness, high stability, and improve production efficiency. In addition, it is also helpful for reducing load and extending life. High definition Composite Plate Fit - 3K CNC carbon fiber cutting opener part for composite frame – Feimoshi , The product will supply to all over the world, such as: New Zealand, Mali, Marseille, There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.