Factory Supply Solid Composite Plate - Forged carbon composite carbon fiber fabric custom forged plate – Feimoshi

Factory Supply Solid Composite Plate - Forged carbon composite carbon fiber fabric custom forged plate – Feimoshi Detail:

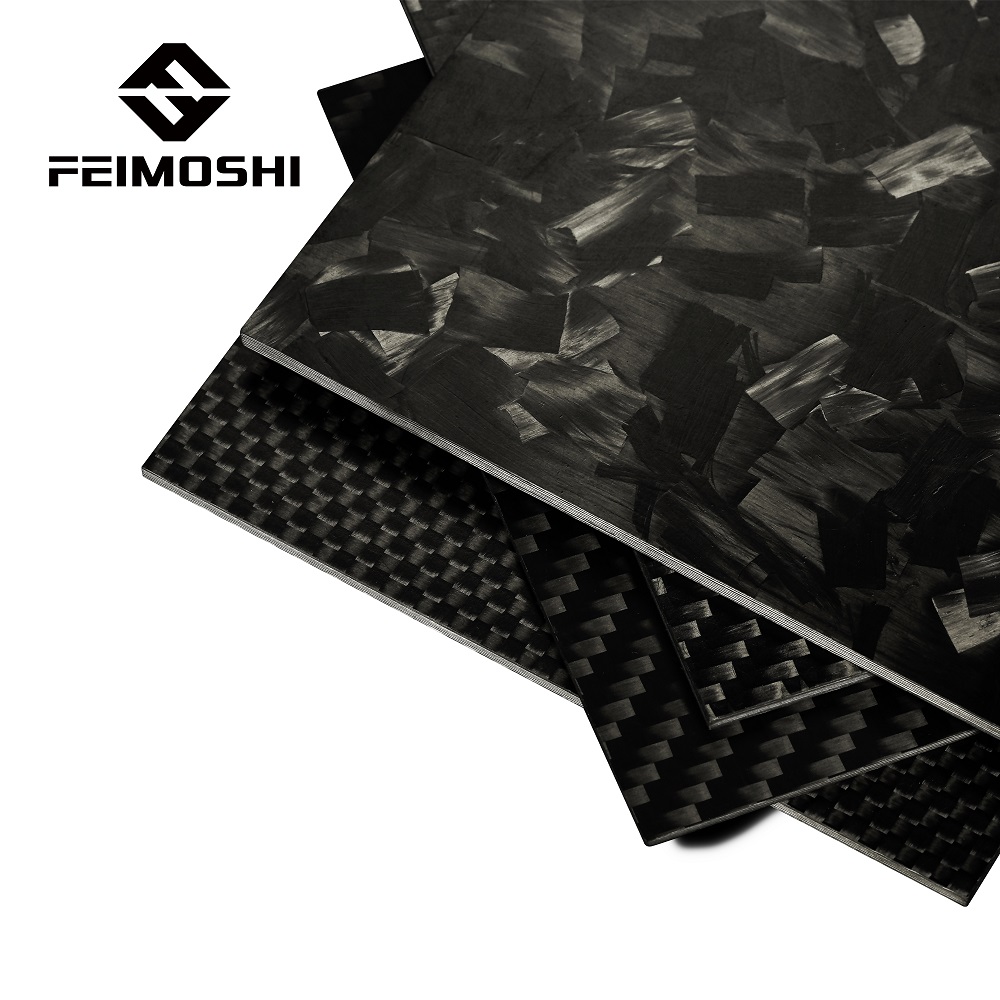

Forged carbon composite carbon fiber fabric custom forged plate

roduct Description:

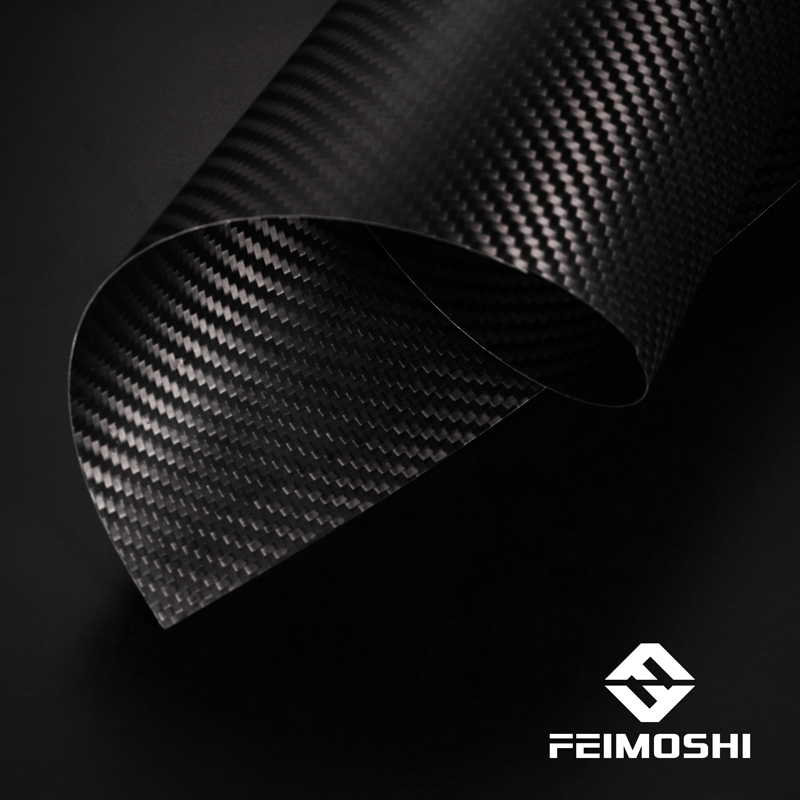

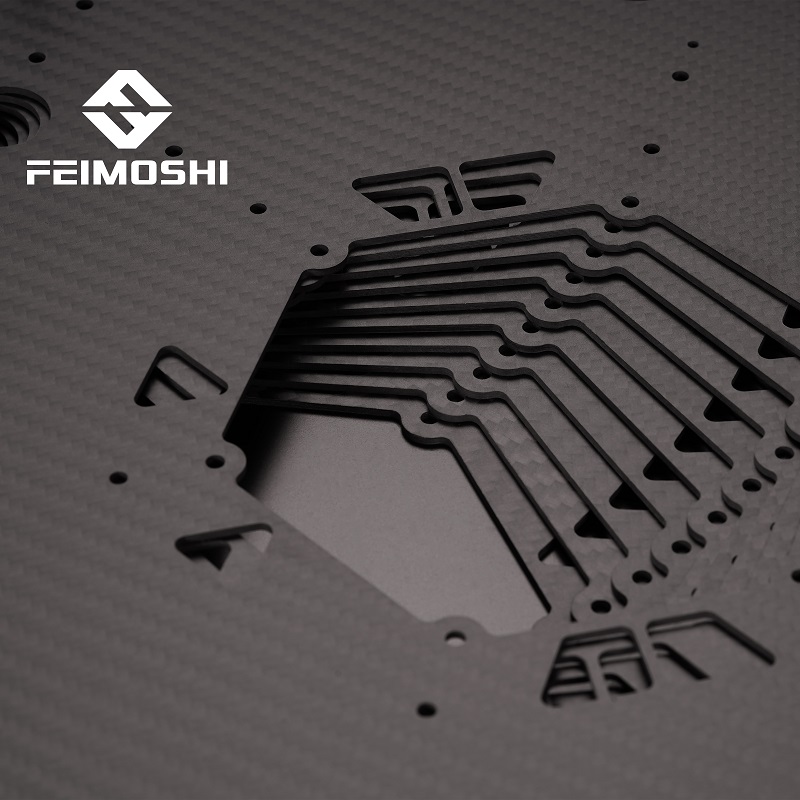

The Forged Carbon Fiber Sheet or Forged Carbon Fiber Plate is manufactured using 100% carbon fiber reinforcement and epoxy resin. The surface can choose from will /plain, matte/glossy. without any glass fiber contents. It is especially applicable for FPV frames, helicopters, and RC airplanes. We are able to do Carbon Fiber CNC cutting Parts for RC Helicopter, RC cars, UAV frame, drone frame, multi-copter frame, camera gimbal frame or others per your specifications. Our factory use imported Japan TORAY or Taiwan TAIRYFIL carbon fiber fabric to make the carbon fiber plates/carbon fiber sheets.

Product Feature:

Strengthening material for C/C compound material;

High strength, lighter weight, imported raw material from Taiwan and Japan;

Filtration material under high temperature and for caustic liquid;

Electric conduct material, electrode & Static electricity resistance.

Product Application:

1. Aerospace, RC model parts Helicopters Model Drone, UAVS

2. Decoration parts for Car and jewelry

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

Product detail pictures:

Related Product Guide:

The basic properties of chopped carbon fiber are mainly inherited from its raw material, continuous carbon fiber. What kind of continuous carbon fiber is used as the raw material also directly determines the price of chopped carbon fiber. The tensile strength of continuous carbon fibers directly affects the tensile properties of chopped carbon fiber composite thermoplastics. Some chopped carbon fiber manufacturers will mix different types of continuous carbon fibers due to insufficient raw material supply or cost issues, but this will lead to unstable properties of chopped carbon fiber composite thermoplastic materials. Therefore, when purchasing chopped carbon fiber, it is best to ask the supplier to indicate the type or main performance of continuous carbon fiber on the quality inspection sheet. Factory Supply Solid Composite Plate - Forged carbon composite carbon fiber fabric custom forged plate – Feimoshi , The product will supply to all over the world, such as: Thailand, Islamabad, Uruguay, In general, grinding and filing can grind the edges of sharp carbon fiber boards to a smooth appearance. However, if the fiberboard is exposed to harsh environments for a long time, such as marine environments, a two-part epoxy laminate is used to seal the edges.According to the different divisions of carbon fiber precursors, there are generally pitch-based carbon fiber cloth, PAN-based carbon fiber cloth, and viscose-based carbon fiber cloth.Second, according to different specifications, it can be divided into 1K, 3K, 6K, 12K and 24K and above carbon fiber cloth.Third, according to different carbonization, it can also be divided into graphitized carbon fiber cloth, (this carbon fiber cloth can withstand high temperature of 2,000 to 3,000), carbon fiber cloth (can cope with high temperature of about 1,000 degrees), and pre-oxidized carbon fiber cloth (can Resist the high temperature of 200~3 Baidu).Fourth, according to different manufacturing methods, subsequent divisions can be performed. Woven carbon fiber cloth, generally two-dimensional cloth, three-dimensional cloth and three-dimensional woven cloth, etc.; carbon fiber prepreg cloth, including dry and wet prepreg cloth; carbon fiber non-woven fabric, non-woven fabric, also known as chopped strand mat, Continuous felt, surface felt, stitched felt, etc.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.